- 您的位置:

- 标准下载网 >>

- 标准分类 >>

- 商检行业标准(SN) >>

- SN/T 2095-2008 进出口疏荣中氟啶脲残留量检测方法 高效液相色谱法

标准号:

SN/T 2095-2008

标准名称:

进出口疏荣中氟啶脲残留量检测方法 高效液相色谱法

标准类别:

商检行业标准(SN)

标准状态:

现行-

发布日期:

2008-08-11 -

实施日期:

2009-02-01 出版语种:

简体中文下载格式:

.rar.pdf下载大小:

1.29 MB

标准ICS号:

食品技术>>水果、蔬菜及其制品>>67.080.20蔬菜及其制品中标分类号:

食品>>食品加工与制品>>X26蔬菜加工与制品

部分标准内容:

中华人民共和国出入境检验检疫行业标准SN/T 2095—2008

进出口蔬菜中氟啶脲残留量检测方法高效液相色谱法

Determination of chlorfluazuron residues in vegetables for import and export-Highperformanceliquid chromatographicmethod2008-07-17发布

中华人民共和国下载标准就来标准下载网

国家质量监督检验检疫总局

2009-02-01实施

本标准的附录A是资料性附录。

本标准由国家认证认可监督管理委员会提出并归口。本标准由中华人民共和国浙江出人境检验检疫局负责起草本标准主要起草人:刘海山、陈笑梅、石蕾、池浩超、汤杭燕、杨磊本标准系首次发布的出入境检验检疫行业标准SN/T2095—2008

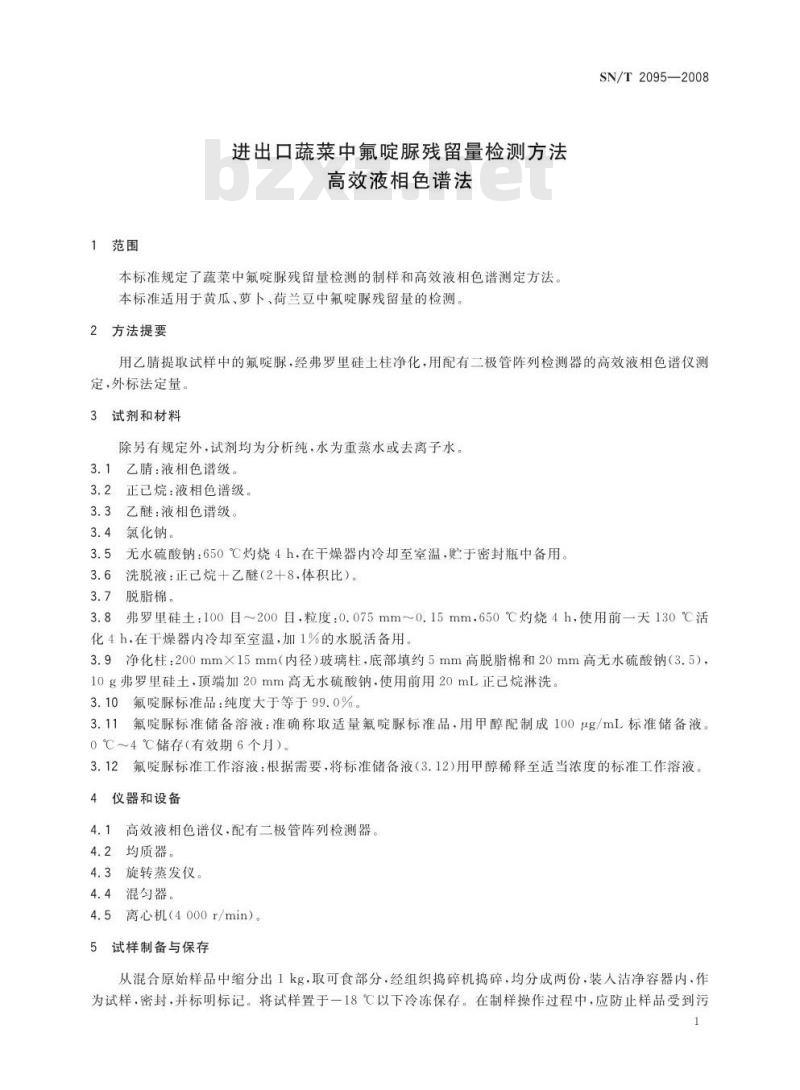

1范围

进出口蔬菜中氟啶脲残留量检测方法高效液相色谱法

本标准规定了蔬菜中氟啶脲残留量检测的制样和高效液相色谱测定方法。本标准适用于黄瓜、萝下、荷兰豆中氟啶腺残留量的检测。2方法提要

SN/T2095—2008

用乙腈提取试样中的氟啶脲,经弗罗里硅土柱净化,用配有二极管阵列检测器的高效液相色谱仪测定,外标法定量。

3试剂和材料

除另有规定外,试剂均为分析纯,水为重蒸水或去离子水。3.1乙睛:液相色谱级。

3.2正已烷:液相色谱级。

3.3乙醚:液相色谱级。

3.4,氯化钠。

3.5无水硫酸钠:650℃灼烧4h,在干燥器内冷却至室温,贮于密封瓶中备用。3.6洗脱液:正已烷十乙醚(2+8.体积比)。3.7脱脂棉,

3.8弗罗里硅土:100目~200目,粒度:0.075mm~0.15mm650℃灼烧4h,使用前一天130℃活化4h在干燥器内冷却至室温,加1%的水脱活备用。3.9净化柱:200mm×15mm(内径)玻璃柱,底部填约5mm高脱脂棉和20mm高无水硫酸钠(3.5),10g弗罗里硅土,顶端加20mm高无水硫酸钠,使用前用20mL正已烷淋洗。3.10氟啶标准品:纯度大于等于99.0%。3.11氟啶脲标准储备溶液:准确称取适量氟啶脲标准品,用甲醇配制成100ug/mL标准储备液。0℃~4℃储存(有效期6个月)。3.12氟啶脲标准工作溶液:根据需要,将标准储备液(3.12)用甲醇稀释至适当浓度的标准工作溶液4仪器和设备

4.1高效液相色谱仪,配有二极管阵列检测器4.2均质器。

4.3旋转蒸发仪。

4.4混匀器。

4.5离心机(4000r/min)。

5试样制备与保存

从混合原始样品中缩分出1kg,取可食部分·经组织捣碎机捣碎,均分成两份,装人洁净容器内·作为试样,密封,并标明标记。将试样置于一18C以下冷冻保存。在制样操作过程中,应防正样品受到污SN/T2095—2008

染或发生残留物含量的变化。

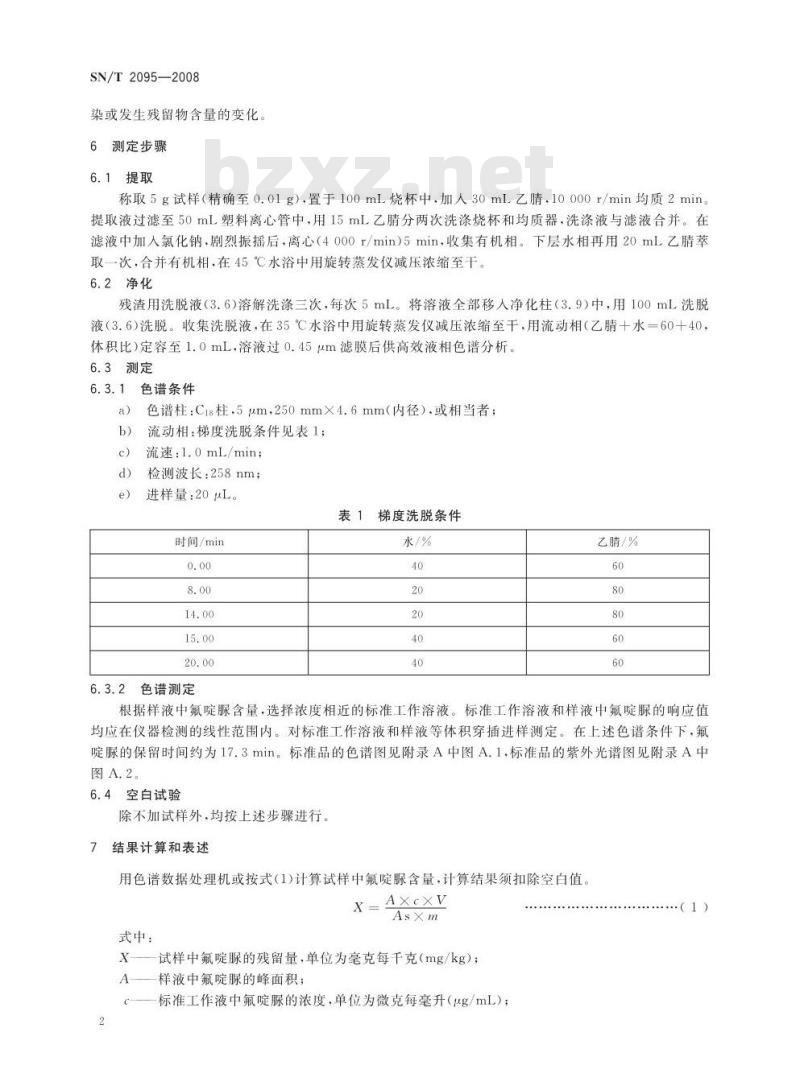

6测定步骤

6.1提取

称取5g试样(精确至0.01g),置于100mL烧杯中,加人30mL乙晴,10000r/min均质2min。提取液过滤至50mL塑料离心管中,用15mL乙睛分两次洗涤烧杯和均质器,洗涤液与滤液合并。在滤液中加人氯化钠.剧烈振摇后,离心(4000r/min)5min,收集有机相。下层水相再用20mL乙萃取一次,合并有机相,在45℃水浴中用旋转蒸发仪减压浓缩至干。6.2净化

残渣用洗脱液(3.6)溶解洗涤三次,每次5mL。将溶液全部移人净化柱(3.9)中,用100mL洗脱液(3.6)洗脱。收集洗脱液,在35℃水浴中用旋转蒸发仪减压浓缩至干,用流动相(乙睛+水=60十40,体积比)定容至1.0mL,溶液过0.45μm滤膜后供高效液相色谱分析。6.3测定

6.3.1色谱条件

色谱柱:Cl:柱,5um,250mm×4.6mm(内径),或相当者;流动相:梯度洗脱条件见表1;

流速:1.0mL/min;

检测波长:258nm;

进样量:20μL。

表1梯度洗脱条件

时间/min

6.3.2色谱测定

乙腈/%

根据样液中氟啶脲含量,选择浓度相近的标准工作溶液。标准工作溶液和样液中氟脲的响应值均应在仪器检测的线性范围内。对标准工作溶液和样液等体积穿插进样测定。在上述色谱条件下,氟啶脲的保留时间约为17.3min。标准品的色谱图见附录A中图A.1,标准品的紫外光谱图见附录A中图A.2。

6.4空白试验

除不加试样外,均按上述步骤进行结果计算和表述

用色谱数据处理机或按式(1)计算试样中氟啶脲含量,计算结果须扣除空白值。AXcXV

式中:

X试样中氟啶脲的残留量,单位为毫克每千克(mg/kg);A

样液中氟啶脲的峰面积:

标准工作液中氟啶豚的浓度,单位为微克每毫升(μg/mL);2

..(1)

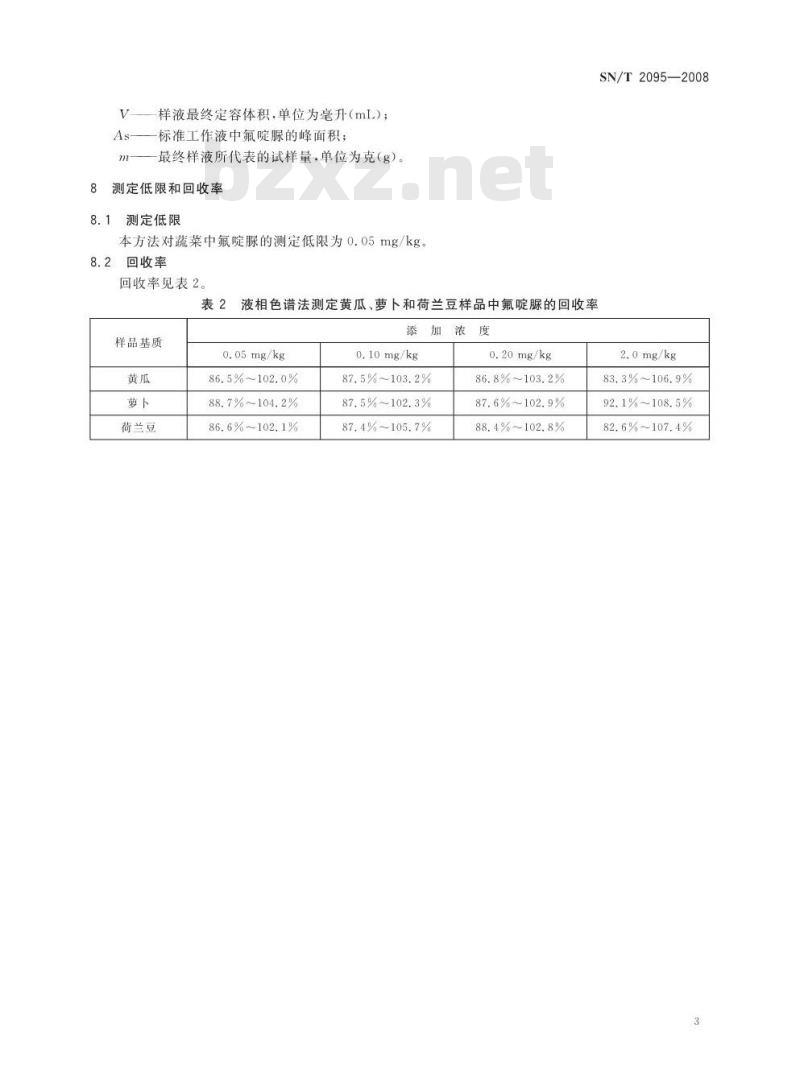

样液最终定容体积,单位为毫升(mL);As——标准工作液中氟啶脲的峰面积;m——最终样液所代表的试样量,单位为克(g))。测定低限和回收率

测定低限

本方法对蔬菜中氟啶脲的测定低限为0.05mg/kg。8.2

回收率

回收率见表2。

样品基质

液相色谱法测定黄瓜、萝卜和荷兰豆样品中氟啶脲的回收率加浓度

0.05mg/kg

荷兰豆

86.5%~102.0%

88.7%~104.2%

86.6%~102.1%

0.10mg/kg

87.5%~103.2%

87.5%~102.3%

87.4%~105.7%

0.20mg/kg

86.8%~103.2%

87.6%~102.9%

88.4%~102.8%

SN/T2095—2008

83.3%~106.9%

92.1%~108.5%

82.6%~107.4%

SN/T2095—2008

附录A

(资料性附录)

标准品色谱图和紫外光谱图

氟啶脲标准品的液相色谱图

氟啶脲标准品的紫外光谱图

AnnexAisan informativeannex

Foreword

SN/T2095—2008

This standard is proposed by and is under the charge of Certification and Accreditation administrationofthePeople'sRepublicof China.This standard was drafted by Zhejiang Entry-Exit Inspection and Quarantine Bureau of the People'sRepublic of China

The main drafters of this standard are Liu Haishan,Chen Xiaomei,Shi Lei,Chi Haochao,Tang Hangyan, Yang Lei.

This standard is a professional standard for entry-exit inspection and quarantine promulgated for thefirsttime.

SN/T2095—2008

Determination of chlorfluazuron residues in vegetablesforimport and exportHighperformanceliquidchromatographicmethod

This standard specifies the method of sample preparation and determination of chlorfluazuron resi-dues invegetablesbyhighperformanceliquidchromatography.This standard is applicable to the determination of chlorfluazuron residues in cucumber, radish andgreen soy bean.

Principle

Chlorfluazuronresidue isextractedbyacetonitrilefromthesample.Cleanuptheextractionbypassing througha florisil column.Determine chlorfluazuron by HPLC with diode array detector and quan-titatewithexternal standardmethod.3

Reagents and materials

Unless specified notes,all reagents are analyticallypure,\water\is redistilled or deionized.3.1

Acetonitrile:HPLC grade

n-Hexane:HPLCgrade

Ethyl ether:HPLC grade

Sodium chloride.

Anhydrous sodium sulfate:Lgnite at 65o for 4 h,and keep in a tightly closed container aftercooling.

Eluent:n-Hexane+ethylether(2+8,V/V).Absorbentcotton.

SN/T2095—2008

3.8Florisil:Granulesize0.075mm~0.15mm(100~200mesh).igniteat650℃for4h,andkeepin a tightly closed container,then heat for 4 h at 130 ℃ in an oven,cooling to room temperature indesiccator and adding 1% of water before use.3.9Columnforclean-up:200mmX15mm(i.d.)glasscolumn,packedwith5mmabsorbentcottonat the bottom of the column.fill in 20 mm anhydrous sodium sulfate,10 g florisil,and 20 mm anhydroussodiumsulfateattop.Add20mLn-hexanetowashbeforeuse.3.10

Chlorfluazuronstandard:Purity≥99.0%Chlorfluazuron standard stocksolution:Accurately weigh an appropriate amountof Chlorflua-3.11

zuron standard and dissolve with methanol to prepare a standard stock solution of 1oo μg/mL.Thisstandard stock solution should be stored at o ℃ ~4 ℃. The standard stock solution is stable in sixmonths.

Chlorfluazuron standard working solution:According to the requirement,pipette adequate a-mount of standard stock solution(3.12) and dilute with methanol to prepare standard working solu-tionof suitableconcentration.4

Apparatusandequipment

Highperformance liquid chromatograph,equipped withdiodearraydetector.Highspeedblender

Rotaryvacuumevaporator.

Vortex mixer.

Centrifuge(4000 r/min).

5Preparationand storageoftestsampleThe combined sample is reduced to 1kg,the edible portion is blended,and divided into two equalportions.Each portion is placed in a clear container as the test sample,which is sealed and labled.Thetest sample shouldbe stored below-18 .In the course of samplepreparation,precautionmust be taken to avoid the contamination or any factors which may cause the change of residue con-tent.

SN/T2095—2008

Determinationprocedure

Extraction

Weigh ca 5 g test sample(accurate to 0.01 g) in 100 mL beaker. Add 30 mL acetonitrile and homoge-nize the sample with the blender at 10 000 r/min for2 min.Filtrate the extraction to 50 mL centrifu-gal tube. Wash the beaker and the blender twice with 15 mL acetonitrile aggregately. Filtrate thewashing solution to the centrifugal tube. Add some Sodium chloride into the filtrate and shake thetube vigrously.Centrifugate(4000 r/min)for5minandcollect the organicphase.Add20mLaceto-nitrile to water phase to extrat again. Combine acetonitrile phase and evaporate the organic phase todrynessat45℃.

Cleanup

Dissolve the residue for three times,using 5 mL eluent(3. 6) each time,and transfer all the solutionto column for clean-up(3.9),elute the column with 100 mL eluent(3. 6). Collect all the eluted solu-tion and evaporate the solution to dryness at 35 C. Dissolve the residue with 1. 0 mL mobile phase(acetonitrile+water=60+40.V/V)and filtrate the solutionby0.45μm filterforhigh-performanceliquidchromatographicdetermination.6.3

Determination

HPLCconditions

Chromatographiccolumn:C1.5μm,250mmx4.6mm(i.d.),orequivalent;Mobile phase:for gradient elute condition,see table 1;b)

Mobilephaseflowrate:1.0mL/min;Detectingwavelength:258nm;

Injection volume: 20 μL.

Table1-Gradienteluteconditiontime/min

water/%

acetonitrile/%

6.3.2HPLCdetermination

SN/T2095—2008

According to the approximate concentration of chlorfluazuron in the sample solution,select thestandard working solution with similar concentration to that of sample solution. The responses ofchlorfluazuron in the standard working solution and the sample solution should be in the linear rangeof the instrumental detection.The standard solution should be randomly injected between the injec-tions of sample solution of equal volume.Under the above operating conditions,the retention timeof chlorfluazuron is about 17.3 min. For the chromatogram of the standard,see figure A. 1 in annexA,andfortheUv spectrumofthestandardseefigureA.2inannexA.6.4 Blank test

The operation of the blank test is the same as the method described in the determination procedurebut with the omission of sample addition.7

Calculation and expression of resultThe calculation of result is carried out by data processor or according to formula(1),and the blankvalue shallbe subtracted fromthe resultof calculation.x=

X-the residue content of chlorfluazuron in the test sample,mg/kg;Athepeak areaof chlorfluazuron insamplesolution;cthe concentration of chlorfluazuron in the standard working solution,μg/mL;Vthefinalvolumeof samplesolution,mL;Asthepeakareaof chlorfluazuroninthestandardworkingsolution;m-thecorrespondingmassofthetestsampleinthefinalsamplesolution.g.8Limitofquantification(LOQ)andrecoveryLimitof quantification

The limit of determination of this method is 0. 05 mg/kg8.2

Recovery

Recoveryseetable2

SN/T2095—2008

Sample

cucumber

radish

green soy bean

0.05mg/kg

86.5%~102.0%

88.7%~104.2%

86.6%~102.1%

Table2—Recovery

Fortifying concentrations

0.10mg/kg

87.5%~103.2%

87.5%~102.3%

87.4%~105.7%

0.20mg/kg

86.8%~103.2%

87.6%~102.9%

88.4%~102.8%

83. 3% ~106. 9%

92. 1% ~108.5%

82.6%~107.4%

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

进出口蔬菜中氟啶脲残留量检测方法高效液相色谱法

Determination of chlorfluazuron residues in vegetables for import and export-Highperformanceliquid chromatographicmethod2008-07-17发布

中华人民共和国下载标准就来标准下载网

国家质量监督检验检疫总局

2009-02-01实施

本标准的附录A是资料性附录。

本标准由国家认证认可监督管理委员会提出并归口。本标准由中华人民共和国浙江出人境检验检疫局负责起草本标准主要起草人:刘海山、陈笑梅、石蕾、池浩超、汤杭燕、杨磊本标准系首次发布的出入境检验检疫行业标准SN/T2095—2008

1范围

进出口蔬菜中氟啶脲残留量检测方法高效液相色谱法

本标准规定了蔬菜中氟啶脲残留量检测的制样和高效液相色谱测定方法。本标准适用于黄瓜、萝下、荷兰豆中氟啶腺残留量的检测。2方法提要

SN/T2095—2008

用乙腈提取试样中的氟啶脲,经弗罗里硅土柱净化,用配有二极管阵列检测器的高效液相色谱仪测定,外标法定量。

3试剂和材料

除另有规定外,试剂均为分析纯,水为重蒸水或去离子水。3.1乙睛:液相色谱级。

3.2正已烷:液相色谱级。

3.3乙醚:液相色谱级。

3.4,氯化钠。

3.5无水硫酸钠:650℃灼烧4h,在干燥器内冷却至室温,贮于密封瓶中备用。3.6洗脱液:正已烷十乙醚(2+8.体积比)。3.7脱脂棉,

3.8弗罗里硅土:100目~200目,粒度:0.075mm~0.15mm650℃灼烧4h,使用前一天130℃活化4h在干燥器内冷却至室温,加1%的水脱活备用。3.9净化柱:200mm×15mm(内径)玻璃柱,底部填约5mm高脱脂棉和20mm高无水硫酸钠(3.5),10g弗罗里硅土,顶端加20mm高无水硫酸钠,使用前用20mL正已烷淋洗。3.10氟啶标准品:纯度大于等于99.0%。3.11氟啶脲标准储备溶液:准确称取适量氟啶脲标准品,用甲醇配制成100ug/mL标准储备液。0℃~4℃储存(有效期6个月)。3.12氟啶脲标准工作溶液:根据需要,将标准储备液(3.12)用甲醇稀释至适当浓度的标准工作溶液4仪器和设备

4.1高效液相色谱仪,配有二极管阵列检测器4.2均质器。

4.3旋转蒸发仪。

4.4混匀器。

4.5离心机(4000r/min)。

5试样制备与保存

从混合原始样品中缩分出1kg,取可食部分·经组织捣碎机捣碎,均分成两份,装人洁净容器内·作为试样,密封,并标明标记。将试样置于一18C以下冷冻保存。在制样操作过程中,应防正样品受到污SN/T2095—2008

染或发生残留物含量的变化。

6测定步骤

6.1提取

称取5g试样(精确至0.01g),置于100mL烧杯中,加人30mL乙晴,10000r/min均质2min。提取液过滤至50mL塑料离心管中,用15mL乙睛分两次洗涤烧杯和均质器,洗涤液与滤液合并。在滤液中加人氯化钠.剧烈振摇后,离心(4000r/min)5min,收集有机相。下层水相再用20mL乙萃取一次,合并有机相,在45℃水浴中用旋转蒸发仪减压浓缩至干。6.2净化

残渣用洗脱液(3.6)溶解洗涤三次,每次5mL。将溶液全部移人净化柱(3.9)中,用100mL洗脱液(3.6)洗脱。收集洗脱液,在35℃水浴中用旋转蒸发仪减压浓缩至干,用流动相(乙睛+水=60十40,体积比)定容至1.0mL,溶液过0.45μm滤膜后供高效液相色谱分析。6.3测定

6.3.1色谱条件

色谱柱:Cl:柱,5um,250mm×4.6mm(内径),或相当者;流动相:梯度洗脱条件见表1;

流速:1.0mL/min;

检测波长:258nm;

进样量:20μL。

表1梯度洗脱条件

时间/min

6.3.2色谱测定

乙腈/%

根据样液中氟啶脲含量,选择浓度相近的标准工作溶液。标准工作溶液和样液中氟脲的响应值均应在仪器检测的线性范围内。对标准工作溶液和样液等体积穿插进样测定。在上述色谱条件下,氟啶脲的保留时间约为17.3min。标准品的色谱图见附录A中图A.1,标准品的紫外光谱图见附录A中图A.2。

6.4空白试验

除不加试样外,均按上述步骤进行结果计算和表述

用色谱数据处理机或按式(1)计算试样中氟啶脲含量,计算结果须扣除空白值。AXcXV

式中:

X试样中氟啶脲的残留量,单位为毫克每千克(mg/kg);A

样液中氟啶脲的峰面积:

标准工作液中氟啶豚的浓度,单位为微克每毫升(μg/mL);2

..(1)

样液最终定容体积,单位为毫升(mL);As——标准工作液中氟啶脲的峰面积;m——最终样液所代表的试样量,单位为克(g))。测定低限和回收率

测定低限

本方法对蔬菜中氟啶脲的测定低限为0.05mg/kg。8.2

回收率

回收率见表2。

样品基质

液相色谱法测定黄瓜、萝卜和荷兰豆样品中氟啶脲的回收率加浓度

0.05mg/kg

荷兰豆

86.5%~102.0%

88.7%~104.2%

86.6%~102.1%

0.10mg/kg

87.5%~103.2%

87.5%~102.3%

87.4%~105.7%

0.20mg/kg

86.8%~103.2%

87.6%~102.9%

88.4%~102.8%

SN/T2095—2008

83.3%~106.9%

92.1%~108.5%

82.6%~107.4%

SN/T2095—2008

附录A

(资料性附录)

标准品色谱图和紫外光谱图

氟啶脲标准品的液相色谱图

氟啶脲标准品的紫外光谱图

AnnexAisan informativeannex

Foreword

SN/T2095—2008

This standard is proposed by and is under the charge of Certification and Accreditation administrationofthePeople'sRepublicof China.This standard was drafted by Zhejiang Entry-Exit Inspection and Quarantine Bureau of the People'sRepublic of China

The main drafters of this standard are Liu Haishan,Chen Xiaomei,Shi Lei,Chi Haochao,Tang Hangyan, Yang Lei.

This standard is a professional standard for entry-exit inspection and quarantine promulgated for thefirsttime.

SN/T2095—2008

Determination of chlorfluazuron residues in vegetablesforimport and exportHighperformanceliquidchromatographicmethod

This standard specifies the method of sample preparation and determination of chlorfluazuron resi-dues invegetablesbyhighperformanceliquidchromatography.This standard is applicable to the determination of chlorfluazuron residues in cucumber, radish andgreen soy bean.

Principle

Chlorfluazuronresidue isextractedbyacetonitrilefromthesample.Cleanuptheextractionbypassing througha florisil column.Determine chlorfluazuron by HPLC with diode array detector and quan-titatewithexternal standardmethod.3

Reagents and materials

Unless specified notes,all reagents are analyticallypure,\water\is redistilled or deionized.3.1

Acetonitrile:HPLC grade

n-Hexane:HPLCgrade

Ethyl ether:HPLC grade

Sodium chloride.

Anhydrous sodium sulfate:Lgnite at 65o for 4 h,and keep in a tightly closed container aftercooling.

Eluent:n-Hexane+ethylether(2+8,V/V).Absorbentcotton.

SN/T2095—2008

3.8Florisil:Granulesize0.075mm~0.15mm(100~200mesh).igniteat650℃for4h,andkeepin a tightly closed container,then heat for 4 h at 130 ℃ in an oven,cooling to room temperature indesiccator and adding 1% of water before use.3.9Columnforclean-up:200mmX15mm(i.d.)glasscolumn,packedwith5mmabsorbentcottonat the bottom of the column.fill in 20 mm anhydrous sodium sulfate,10 g florisil,and 20 mm anhydroussodiumsulfateattop.Add20mLn-hexanetowashbeforeuse.3.10

Chlorfluazuronstandard:Purity≥99.0%Chlorfluazuron standard stocksolution:Accurately weigh an appropriate amountof Chlorflua-3.11

zuron standard and dissolve with methanol to prepare a standard stock solution of 1oo μg/mL.Thisstandard stock solution should be stored at o ℃ ~4 ℃. The standard stock solution is stable in sixmonths.

Chlorfluazuron standard working solution:According to the requirement,pipette adequate a-mount of standard stock solution(3.12) and dilute with methanol to prepare standard working solu-tionof suitableconcentration.4

Apparatusandequipment

Highperformance liquid chromatograph,equipped withdiodearraydetector.Highspeedblender

Rotaryvacuumevaporator.

Vortex mixer.

Centrifuge(4000 r/min).

5Preparationand storageoftestsampleThe combined sample is reduced to 1kg,the edible portion is blended,and divided into two equalportions.Each portion is placed in a clear container as the test sample,which is sealed and labled.Thetest sample shouldbe stored below-18 .In the course of samplepreparation,precautionmust be taken to avoid the contamination or any factors which may cause the change of residue con-tent.

SN/T2095—2008

Determinationprocedure

Extraction

Weigh ca 5 g test sample(accurate to 0.01 g) in 100 mL beaker. Add 30 mL acetonitrile and homoge-nize the sample with the blender at 10 000 r/min for2 min.Filtrate the extraction to 50 mL centrifu-gal tube. Wash the beaker and the blender twice with 15 mL acetonitrile aggregately. Filtrate thewashing solution to the centrifugal tube. Add some Sodium chloride into the filtrate and shake thetube vigrously.Centrifugate(4000 r/min)for5minandcollect the organicphase.Add20mLaceto-nitrile to water phase to extrat again. Combine acetonitrile phase and evaporate the organic phase todrynessat45℃.

Cleanup

Dissolve the residue for three times,using 5 mL eluent(3. 6) each time,and transfer all the solutionto column for clean-up(3.9),elute the column with 100 mL eluent(3. 6). Collect all the eluted solu-tion and evaporate the solution to dryness at 35 C. Dissolve the residue with 1. 0 mL mobile phase(acetonitrile+water=60+40.V/V)and filtrate the solutionby0.45μm filterforhigh-performanceliquidchromatographicdetermination.6.3

Determination

HPLCconditions

Chromatographiccolumn:C1.5μm,250mmx4.6mm(i.d.),orequivalent;Mobile phase:for gradient elute condition,see table 1;b)

Mobilephaseflowrate:1.0mL/min;Detectingwavelength:258nm;

Injection volume: 20 μL.

Table1-Gradienteluteconditiontime/min

water/%

acetonitrile/%

6.3.2HPLCdetermination

SN/T2095—2008

According to the approximate concentration of chlorfluazuron in the sample solution,select thestandard working solution with similar concentration to that of sample solution. The responses ofchlorfluazuron in the standard working solution and the sample solution should be in the linear rangeof the instrumental detection.The standard solution should be randomly injected between the injec-tions of sample solution of equal volume.Under the above operating conditions,the retention timeof chlorfluazuron is about 17.3 min. For the chromatogram of the standard,see figure A. 1 in annexA,andfortheUv spectrumofthestandardseefigureA.2inannexA.6.4 Blank test

The operation of the blank test is the same as the method described in the determination procedurebut with the omission of sample addition.7

Calculation and expression of resultThe calculation of result is carried out by data processor or according to formula(1),and the blankvalue shallbe subtracted fromthe resultof calculation.x=

X-the residue content of chlorfluazuron in the test sample,mg/kg;Athepeak areaof chlorfluazuron insamplesolution;cthe concentration of chlorfluazuron in the standard working solution,μg/mL;Vthefinalvolumeof samplesolution,mL;Asthepeakareaof chlorfluazuroninthestandardworkingsolution;m-thecorrespondingmassofthetestsampleinthefinalsamplesolution.g.8Limitofquantification(LOQ)andrecoveryLimitof quantification

The limit of determination of this method is 0. 05 mg/kg8.2

Recovery

Recoveryseetable2

SN/T2095—2008

Sample

cucumber

radish

green soy bean

0.05mg/kg

86.5%~102.0%

88.7%~104.2%

86.6%~102.1%

Table2—Recovery

Fortifying concentrations

0.10mg/kg

87.5%~103.2%

87.5%~102.3%

87.4%~105.7%

0.20mg/kg

86.8%~103.2%

87.6%~102.9%

88.4%~102.8%

83. 3% ~106. 9%

92. 1% ~108.5%

82.6%~107.4%

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

标准图片预览:

- 热门标准

- 商检行业标准(SN)

- SN/T1509-2005 异尖线虫病诊断规程

- SN/T1672.7-2013 进出口医用设备检验规程 第7部分:医用内窥镜

- SN/T0328-94 出口氟石中氟化钙的化学分析方法

- SN/T1083.1-2002 焦炭分析试样水分、灰分的快速测定

- SN/T1359.2-2004 进口纺织机械检验规程 织袜机

- SN/T1395.2-2005 禽衣原体病琼脂免疫扩散试验操作规程

- SN/T1443.2-2004 食品安全管理体系 审核指南

- SN0665-1997 出口肉及肉制品中雌三醇残留量检验方法放射免疫法

- SN/T0226.2-1993 出口冻公鱼检验规程

- SN/T0380-1995 出口活鱼检验规程

- SN/T0801.6-1999 进出口动植物油脂沉积物检验方法

- SN/T1891.6-2007 进出口微波食品包装容器及包装材料卫生标准 第6部分:玻璃制品

- SN/T2552.1-2010 乳及乳制品卫生微生物学检验方法 第1部分:取样指南

- SN/T3719.1-2013 进出口纺织行业成套设备检验技术要求 第1部分化纤设备

- SN/T3683-2013 松针褐枯病菌检疫鉴定方法

- 行业新闻

请牢记:“bzxz.net”即是“标准下载”四个汉字汉语拼音首字母与国际顶级域名“.net”的组合。 ©2025 标准下载网 www.bzxz.net 本站邮件:bzxznet@163.com

网站备案号:湘ICP备2025141790号-2

网站备案号:湘ICP备2025141790号-2