- 您的位置:

- 标准下载网 >>

- 标准分类 >>

- 商检行业标准(SN) >>

- SN/T 2052-2008 进出口水产品中一氧化碳残留量检验方法气相色谱法

标准号:

SN/T 2052-2008

标准名称:

进出口水产品中一氧化碳残留量检验方法气相色谱法

标准类别:

商检行业标准(SN)

标准状态:

现行-

发布日期:

2008-04-29 -

实施日期:

2008-11-01 出版语种:

简体中文下载格式:

.rar.pdf下载大小:

220.04 KB

标准ICS号:

食品技术>>67.050食品试验和分析的一般方法中标分类号:

食品>>食品加工与制品>>X20水产品加工与制品

部分标准内容:

中华人民共和国出入境检验检疫行业标准SN/T 2052—2008

进出口水产品中一氧化碳残留量的检验方法

气相色谱法

Inspection of carbon monoxide residues in aquatic productsfor import and exportGas chromatography method2008-04-29发布

中华人民共和国

国家质量监督检验检疫总局

2008-11-01实施

本孙准闷附录A为资料性附录

本标滩山国家认证认可监督管理菱员会提出并归口本标淮起卢单位:中华人民!和国上海出人境检验检后、上海水产大学。本弥准工要起市人:李波、郭德华、邓琥乖、吴核呆、陈葬牡、殿平、李茹本标准系前款发布的出入境检验检疫行业标准。S>/T2052—2008

1范围

进出口水产品中一氧化碳残留量的法气相色谱法

检验方法

S>/T 2052—2008

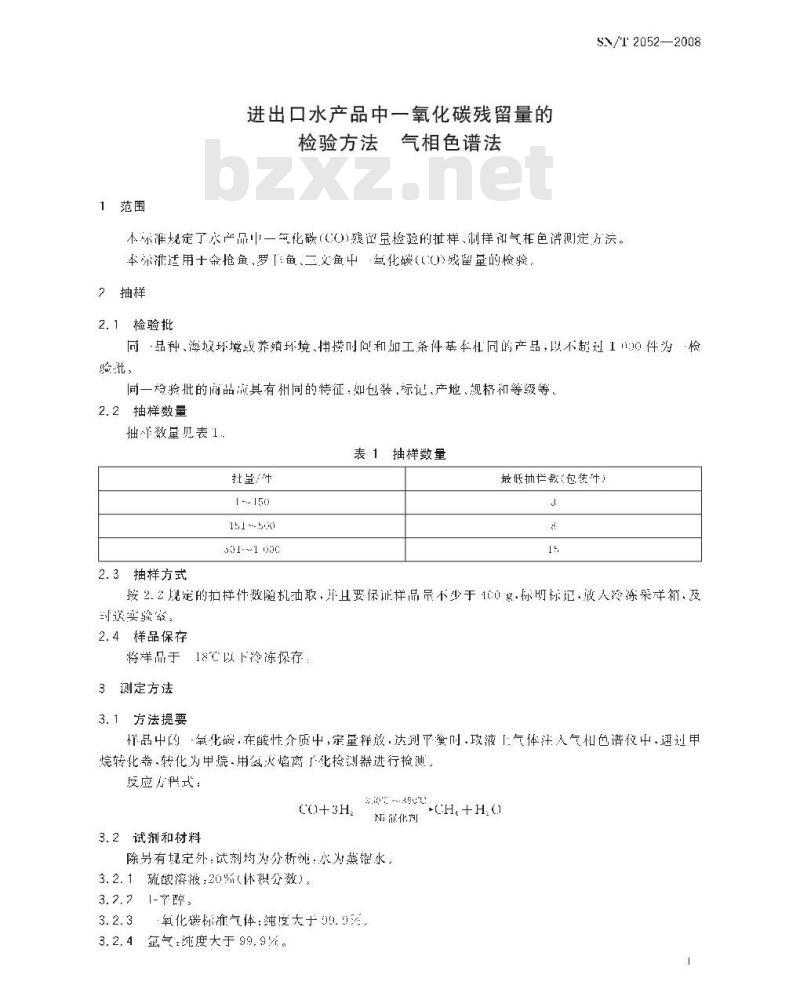

本标准划定了水产品中一化磁((())残逆量检验的推样、制样和气相色谱测定方法。本雅适用十金抢鱼、罗鱼、三义鱼中弯化碳(())战留量的检验,2抽样

2.1检验批

向品种、海故坏境或养殖坏境、捕捞叫问和加工条件基本札同的产品,以不超过1件为检验批。

一检验批的商品成具有州同的特征,如包装,标记,产地、规格和等级等,2.2抽样数量

抽数量见表1,

表 1抽样数量

批呈/件

3311 0ac

2.3抽样方式

最低抽栏数包装件!

按2.2现定的拍样件数随机油取,并且要保证样品员不少于1(0·标明标记·放人冷冻采详箱,及封送实鉴室

2.4样品保存

将样品于,18℃以下冷陈保存

3测定方法

3.1方法提要

样品中的-氧化碳.在酸性介质中,定量释放·达到平黛玟液「气体注入气扣色谱仪中.划甲烷转化养、转化为甲烷、用氢大焰离了化检测器进行检测反应店程式:

3.2试剂和材料

3i? -R80'C

+CH, +HO

Ni化剂

除另有规定外:试剂均为分析纯:水为蒸馏水3.2.1硫酸溶液,20%(体积分数)3.2.2 1-文醇,

氧化碳标准气体:纯度大于09.0法3. 2. 4 氩气.纯度大于 99. 9%。$N/T 2052—2008

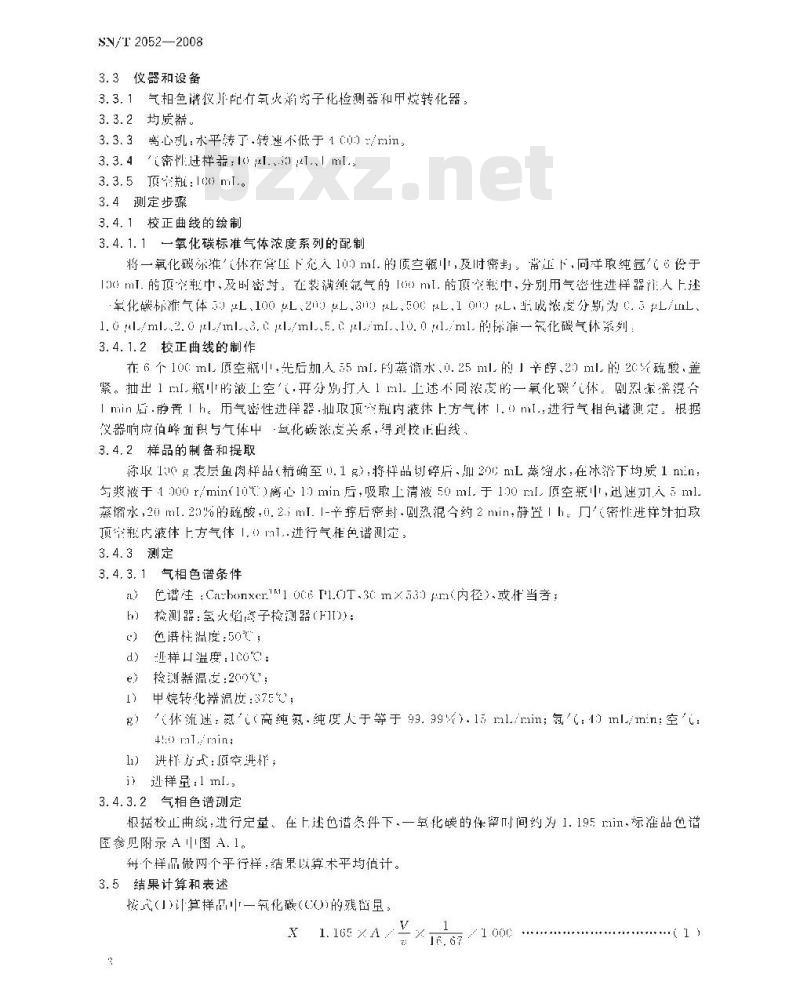

3.3器和设备

3.3.1气相色谱俊Ⅱ配有氧火炸窝子化检测器和甲烷转化器,3.3.2均质。

3.3.3离心矶:水平转了.转速不低于1(0/1i13.3.4案性进样器.1.1ml.

3. 3.5顶:1eo ml.。

3.4测定步骤

3.4.1校正曲线的绘制

3.4.1.1一氧化碳标准气体浓度系列的配制將一氧化碳弥雅不在营压下态人1m的顺空瓶,及时密封,常下,同详最纯氩偿于Iml.的顶瓶中,及时密对,在装满缅氧气的1ml.的顶窄邦中,分别用气密性进样器注人上述氧化碳标雅气体3 μ,100 L,2 μL,3 50℃uL,1 L,成浓分别为 CL/1. 0 /ml.2.0 μL/ml.,μL/ml,5,μ/ml,1o. 0 nlml.的际准一年化碳气体系划3.4.1.2校正曲线的制作

在6个100:ml,顶空瓶,光后加人55 ml.的蒸水,0.25 ml的」辛婷、2)ml的2(:硫酸,盖紧。抽出1rl,瓶的波上空再分别打人1 ril 上述不同浓的一氧化气体。剧烈案混台Imin后·静置「h。币气密性进样器.灿取顶瓶内液休上方气休1.\ml.进行气相色谱测定,根据仪器响应伯峰直积与气体中-氢化碳浓支关系,得别校正出线,3.4.2样品的制备和提取

称取10g表层鱼肉样品(精确至.1),将样品切碎后加20n蒸密水,在冰溶下均质1nn;每波于 rmin1离心1 min后.吸最上清波5o ml.于l0 rl顶空辉,年速人 ml蒸缩水,20 ml.20%的硫酸.0.2.;ml.1-辛拧后密封.剧熟混今约2 min.静置1h门密性进样针拍取预举内液体上方气体1,:T.进行气椎色谱测定,3.4.3测定

3.4.3.1气相色谱条件

谱注:Cahonxern1o[10T.3(:mX53)m内径).或件当者:h)

检测器:氢火焰离子检测器(FII)):色谱柱温度:50元;

逊样山温度:1coC:

检测器温友:200℃;

甲烷转化器温度:375%℃

(体流迷,氮气(高纯纯度人于等于93.99%).15ml./mnin;氧:4)ml/mn:空气:+!o r:trnin:

l)进样方式:顾空进样,

i)样呈:lml.

3.4.3.2气相色谱测定

根括校止曲线:进行定量。在上述色谱条件下,一氧化碳的保留叫间约为1.1951r1i.标准品色谐医参见附录 A 图 A. 1。

册个样品做两个平行样:结果以算术平均值计。3.5结果计算和表述

按式()计算样品一氧化碳((的留显,1.165XA

试样中一氧化碳())残留量单位为微克每于克()S>/T2052—2008

试样中测役的色谱峰面积在校正山线工所对虚的一氧化碳的含显,单莅为徽升(!);顶净熟中气州体积,单位为室升(mL);气相色谱过样量.单位为毫外(mL);1mol.一氧化体布常注,2时的气体牵,单位为亮克每衰(mg/ml):每取出5(ml的浆上清波中机当于样品的量,节位为克(g)。4方法的测定低限及回收率

4.1测定低限

本法测定低限Q)为)

4.2回收率

添加问收率实验数据如下:

a金枪鱼:

在51μg/kg时回收本为 39. 3%-~84. 8%在21:/kg时.川收率为82.1%-103.8:—在699g/kg时.川收率为86.1-103.2片:罗非鱼:

在30 μ9/ kg时,回收率为 34,4%89. 2%;一在210 μg/kg时.可收率为 73.6穿--96.9法一在699 μg/kg时.可收率为 60.7~-101.2三文:

在 50 μg/k时.同收率为 55,8%~81, 0:在21 1/kg叫.可收率为 74. 8%~104. 8/在699 2g/k%时,可收率为 75.2%-~95. 4$N/T2052—2008

附录A

(资料性附录)

标准品色谱图

1一氧化碳(C0)(0.202μ叫l./ml)的气相色谱图图A.1

Foreword

Annex A of this standard is an infarmative annex.S>/T2052—2008

This stancarc was proposed by and is lincer the charged of certification and accreditation administa-tion of the People's Republic of ChinaThis stancard was drarted by Shanghai Entry-Exit Inspection and Quarantine Bureall ol the People sRepuitblic ar China.Shenghai Fisheries UniversityThe standard was rriainly drafted by Li Bo, Guo Dehua, Derig Xiaojun, Wu Jiale, Chen Shunsherig, Yinping,Li Juan.

This stancarcd is a professional standard for entry-exit inspection and quiarantine promulgated for thefirst time.

Note:this English version:a translation from the Chinese text-is solely fo'guidance5

$N/T2052—2008

Inspectionofcarbonmonoxideresiduesinaguatic products for import and export-Gaschromatographymethod

The standard specilies the methods al sampling: sample preparation and determinatian or carbonmonoxide residues by Gc in aquatic products for export and import.This standard is applicable to the determination of carbon monoxide residues in tuina. tilapia and redsalmon far import and export.2

Sampling

Inspectian lot

The quantity of an inspection lot should not he more than 1 aoo packages which of the type,sea areaor cuiltivating enviarnment :and rishing time should be the sarme.The characteristics of the cargo within the sarrie inspectioni lot,such as packing.mark,origini.specifi-cation and grade. should be the same.2.2

Quantity ol sarmple taken

The quantity of sarmple taken is according to table 1.Table 1-Quantity af sample takenNumber af packages in each inspection lot1~150

151~500

501 ~ 1 000bzxZ.net

Sampling procedure

Minimiim nuimter ol packages to be taken3

A number of packages specified in 2. 2 are taken at random. The sample weight taken as the primarysample from eacl pacdage should be at least 400 g.and sliould be sealed. labeled. frozen and sent tolaboratoryintime.

Storage of sample

The test samples should be stored at - 18'C.3Method of determination

Principle

S>/T 2052—2008

Carbon monoxide residue was released quantitatively from thie sample in acidity mediuim. While bal-ance,the heacspace gas was iniected inta the gas chramatography. CO was separated Trom other ga-ses on the collimn and was reduced to methane in the methanizer for detedtion by FiD,Reaction equation:

CO-3H,

Reagents and materials

350 ~380%

+CH4 + H,O

Unless otherwise speciried:all the reagent Lised should be analytical grade,\water\is distilled water.3.2.1

Sulfate acid solution: 20%( V/ V)3.2.2

n-octyl alcohol.

Standard co gas: purity 99. 9%.Argon gas: purity.99. 9%

Apparatus and equipment

Gas chromatography(equipped withFID and methanizer).High speed blender.

Centrifuge:4 000 r'min.

Gas-tight syringe: 10 μL,50 μL.1 mL.Head-space bottle: 1ao mL

Procedure

Calibration CO gas

CO standard gas series

Filled the purity cO into the 1o0 mL Head-space bottle at the normal atmospheric pressire.and closed$N/T2052—2008

as quickly as possible with a cap which was placed a septum and an O-ring. In the same way filled six100 mL Heacd-space bottles with argon gas,and then inject 99. 9%CO 50 μL.100 μL.200 μL.300 μL.500 L、1D00 μL into them. The CO standard gas series are 0.5 L/mL、1.0 μxL/mL、2. μL/mL、3. 0 rL/rmiL,5. 0 jxL/rriL,10. 0 μxL/mL CO.3.4.1.2co gas calibration seriesIn six 100 mL Head-space bottles,55 mL water.0, 25 mL n-octyl alcolol.20 mL 20% ( V/ V)Sulfateacid solution were added.and they were closed tightly. 1 mL the leadspace gas of these bottles wasdrawn anc then injected separately the Co standard gas series. The mixtures were shaked vigorouslyfor about 1 min.and left for 1 h. 1.0 mL of the head-space gas was taken and injected into the gaschromatograph. According to the response area and the concentration of co.the Co gas calibrationcurve could be obtainecd.

Preparation af test sample and extractionWeigh ca 100 g of the test sample (accurate to 0. 1 g). Sample was miriced.added 200 mL water,ho-mogenized for 1 min in a iced-bath.arid ceritrifuge for 10 min at 4 000 r/min (10'c ). The supernatant,50 mL.was poured into a 100 mL head-space bottle,then 5 mL of water.20 mL 20% ( V/ V) Sulfateacid soluition:0. 25 mL n-octyl alcohal were added. A cap with a septurn and an O-ring was placed onthe bottle: which was closed as quickly as possible. The mixtures were shaked vigorouisly for about2 min.and lelt [or 1 h. 1. d mL ol the head-space gas was taken anc iniected into the gas chramato-graph.

3. 4, 3 Determination

GC operating conditions

Column: Caronxen M 1 00s PLOT,30 m × 530 μmti. d. ).or the equivalent :a

Detector:FID;

Column temperature:50'C :

Injection port temperatuire: 10o' :d

Detector temperatuire:200c ;e)

Methanizer temperature:375'cf)

Carrier gas:N, (purity::99. 99 % ).15 mL/min: H. :40 mL/rrin: Air: 450 rriL/min1;g

h)Injectian mode:head-space;co

i) Injection volume:1 mL.

3. 4. 3.2 GC operating

S>/T2052—2008

According to the CO gas calibration curve,cO residue in flesh could he detected, Under the above Gcoperating condition.the retention time of cO was ahaut 1, 195 min, The chromatograms of the stand-ard see Figure A. 1 in annex AEvery sample should be dauble tested.and the resuilt was mean value.3. 5Calculation and expression af resultCalculation the content of CO residue in thre test sample by GC data processor or according to the formula (1)V

X = 1. 165 × A ×

×1000

theresiduecontentafco inthetestsample.fg/kg:x

A-the concentrationof co inthe test solution from Co gas calibration curveμLV-the voluime of gas in the head-space bottle.mL;yInjection volume.mL:

1.165the density of 1 moL cO at the normal atmaspheric pressuire(20'cC):mg/mL;16. 67-mass of test sample of final sarnple solution.g.4 Limit of quantilalion( LOQ) and recovery4. 1 Limit of quantitation

The limit of quantitation (LoQ) of the method is 5a μg.kg4.2Recovery

According to the experimental data.the fortifying coriceritrations of test sarriple and its correspond.ing recaveries in tuna,tilapia and red salmon are as follows:a)

Fortirying concentrations was 50 μrg: kg : The recoveries were between 69. 6% ~-84. 8% ;Forti[ying concentrations was 21D μg/kg.The recoveries were between 82.4% ~103.8% :Fortifyirig concentrations was 699 pμg/ kg. The recoveries were between 86. 1% ~103. 2% :b)Tilapia:

Fortifying concentrations was 50 μg/kg.The recoveries were between 64. 4% 80.2% ;$N/T 2052—2008

Fortifying concentrations was 210 μg. kg, The recoveries were between 73. 6% ~96. 9% ;Fortifying concentrations was 699 μg/kg-The recoveries were between 69.7% -- 101. 2% :C

Red salmon:

Fortilying concentrations was 50 μg: kg : The recoveries were between 65. 8% ~81. a% :Fortifyirig concentrations was 210 μg/ kg, The recoveries were betweeri 74. 8% ~104. 8% :Fortifying conceritrations was 699 μg/ kg, The recoveries were between 75. 2% ~95. 4%

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

进出口水产品中一氧化碳残留量的检验方法

气相色谱法

Inspection of carbon monoxide residues in aquatic productsfor import and exportGas chromatography method2008-04-29发布

中华人民共和国

国家质量监督检验检疫总局

2008-11-01实施

本孙准闷附录A为资料性附录

本标滩山国家认证认可监督管理菱员会提出并归口本标淮起卢单位:中华人民!和国上海出人境检验检后、上海水产大学。本弥准工要起市人:李波、郭德华、邓琥乖、吴核呆、陈葬牡、殿平、李茹本标准系前款发布的出入境检验检疫行业标准。S>/T2052—2008

1范围

进出口水产品中一氧化碳残留量的法气相色谱法

检验方法

S>/T 2052—2008

本标准划定了水产品中一化磁((())残逆量检验的推样、制样和气相色谱测定方法。本雅适用十金抢鱼、罗鱼、三义鱼中弯化碳(())战留量的检验,2抽样

2.1检验批

向品种、海故坏境或养殖坏境、捕捞叫问和加工条件基本札同的产品,以不超过1件为检验批。

一检验批的商品成具有州同的特征,如包装,标记,产地、规格和等级等,2.2抽样数量

抽数量见表1,

表 1抽样数量

批呈/件

3311 0ac

2.3抽样方式

最低抽栏数包装件!

按2.2现定的拍样件数随机油取,并且要保证样品员不少于1(0·标明标记·放人冷冻采详箱,及封送实鉴室

2.4样品保存

将样品于,18℃以下冷陈保存

3测定方法

3.1方法提要

样品中的-氧化碳.在酸性介质中,定量释放·达到平黛玟液「气体注入气扣色谱仪中.划甲烷转化养、转化为甲烷、用氢大焰离了化检测器进行检测反应店程式:

3.2试剂和材料

3i? -R80'C

+CH, +HO

Ni化剂

除另有规定外:试剂均为分析纯:水为蒸馏水3.2.1硫酸溶液,20%(体积分数)3.2.2 1-文醇,

氧化碳标准气体:纯度大于09.0法3. 2. 4 氩气.纯度大于 99. 9%。$N/T 2052—2008

3.3器和设备

3.3.1气相色谱俊Ⅱ配有氧火炸窝子化检测器和甲烷转化器,3.3.2均质。

3.3.3离心矶:水平转了.转速不低于1(0/1i13.3.4案性进样器.1.1ml.

3. 3.5顶:1eo ml.。

3.4测定步骤

3.4.1校正曲线的绘制

3.4.1.1一氧化碳标准气体浓度系列的配制將一氧化碳弥雅不在营压下态人1m的顺空瓶,及时密封,常下,同详最纯氩偿于Iml.的顶瓶中,及时密对,在装满缅氧气的1ml.的顶窄邦中,分别用气密性进样器注人上述氧化碳标雅气体3 μ,100 L,2 μL,3 50℃uL,1 L,成浓分别为 CL/1. 0 /ml.2.0 μL/ml.,μL/ml,5,μ/ml,1o. 0 nlml.的际准一年化碳气体系划3.4.1.2校正曲线的制作

在6个100:ml,顶空瓶,光后加人55 ml.的蒸水,0.25 ml的」辛婷、2)ml的2(:硫酸,盖紧。抽出1rl,瓶的波上空再分别打人1 ril 上述不同浓的一氧化气体。剧烈案混台Imin后·静置「h。币气密性进样器.灿取顶瓶内液休上方气休1.\ml.进行气相色谱测定,根据仪器响应伯峰直积与气体中-氢化碳浓支关系,得别校正出线,3.4.2样品的制备和提取

称取10g表层鱼肉样品(精确至.1),将样品切碎后加20n蒸密水,在冰溶下均质1nn;每波于 rmin1离心1 min后.吸最上清波5o ml.于l0 rl顶空辉,年速人 ml蒸缩水,20 ml.20%的硫酸.0.2.;ml.1-辛拧后密封.剧熟混今约2 min.静置1h门密性进样针拍取预举内液体上方气体1,:T.进行气椎色谱测定,3.4.3测定

3.4.3.1气相色谱条件

谱注:Cahonxern1o[10T.3(:mX53)m内径).或件当者:h)

检测器:氢火焰离子检测器(FII)):色谱柱温度:50元;

逊样山温度:1coC:

检测器温友:200℃;

甲烷转化器温度:375%℃

(体流迷,氮气(高纯纯度人于等于93.99%).15ml./mnin;氧:4)ml/mn:空气:+!o r:trnin:

l)进样方式:顾空进样,

i)样呈:lml.

3.4.3.2气相色谱测定

根括校止曲线:进行定量。在上述色谱条件下,一氧化碳的保留叫间约为1.1951r1i.标准品色谐医参见附录 A 图 A. 1。

册个样品做两个平行样:结果以算术平均值计。3.5结果计算和表述

按式()计算样品一氧化碳((的留显,1.165XA

试样中一氧化碳())残留量单位为微克每于克()S>/T2052—2008

试样中测役的色谱峰面积在校正山线工所对虚的一氧化碳的含显,单莅为徽升(!);顶净熟中气州体积,单位为室升(mL);气相色谱过样量.单位为毫外(mL);1mol.一氧化体布常注,2时的气体牵,单位为亮克每衰(mg/ml):每取出5(ml的浆上清波中机当于样品的量,节位为克(g)。4方法的测定低限及回收率

4.1测定低限

本法测定低限Q)为)

4.2回收率

添加问收率实验数据如下:

a金枪鱼:

在51μg/kg时回收本为 39. 3%-~84. 8%在21:/kg时.川收率为82.1%-103.8:—在699g/kg时.川收率为86.1-103.2片:罗非鱼:

在30 μ9/ kg时,回收率为 34,4%89. 2%;一在210 μg/kg时.可收率为 73.6穿--96.9法一在699 μg/kg时.可收率为 60.7~-101.2三文:

在 50 μg/k时.同收率为 55,8%~81, 0:在21 1/kg叫.可收率为 74. 8%~104. 8/在699 2g/k%时,可收率为 75.2%-~95. 4$N/T2052—2008

附录A

(资料性附录)

标准品色谱图

1一氧化碳(C0)(0.202μ叫l./ml)的气相色谱图图A.1

Foreword

Annex A of this standard is an infarmative annex.S>/T2052—2008

This stancarc was proposed by and is lincer the charged of certification and accreditation administa-tion of the People's Republic of ChinaThis stancard was drarted by Shanghai Entry-Exit Inspection and Quarantine Bureall ol the People sRepuitblic ar China.Shenghai Fisheries UniversityThe standard was rriainly drafted by Li Bo, Guo Dehua, Derig Xiaojun, Wu Jiale, Chen Shunsherig, Yinping,Li Juan.

This stancarcd is a professional standard for entry-exit inspection and quiarantine promulgated for thefirst time.

Note:this English version:a translation from the Chinese text-is solely fo'guidance5

$N/T2052—2008

Inspectionofcarbonmonoxideresiduesinaguatic products for import and export-Gaschromatographymethod

The standard specilies the methods al sampling: sample preparation and determinatian or carbonmonoxide residues by Gc in aquatic products for export and import.This standard is applicable to the determination of carbon monoxide residues in tuina. tilapia and redsalmon far import and export.2

Sampling

Inspectian lot

The quantity of an inspection lot should not he more than 1 aoo packages which of the type,sea areaor cuiltivating enviarnment :and rishing time should be the sarme.The characteristics of the cargo within the sarrie inspectioni lot,such as packing.mark,origini.specifi-cation and grade. should be the same.2.2

Quantity ol sarmple taken

The quantity of sarmple taken is according to table 1.Table 1-Quantity af sample takenNumber af packages in each inspection lot1~150

151~500

501 ~ 1 000bzxZ.net

Sampling procedure

Minimiim nuimter ol packages to be taken3

A number of packages specified in 2. 2 are taken at random. The sample weight taken as the primarysample from eacl pacdage should be at least 400 g.and sliould be sealed. labeled. frozen and sent tolaboratoryintime.

Storage of sample

The test samples should be stored at - 18'C.3Method of determination

Principle

S>/T 2052—2008

Carbon monoxide residue was released quantitatively from thie sample in acidity mediuim. While bal-ance,the heacspace gas was iniected inta the gas chramatography. CO was separated Trom other ga-ses on the collimn and was reduced to methane in the methanizer for detedtion by FiD,Reaction equation:

CO-3H,

Reagents and materials

350 ~380%

+CH4 + H,O

Unless otherwise speciried:all the reagent Lised should be analytical grade,\water\is distilled water.3.2.1

Sulfate acid solution: 20%( V/ V)3.2.2

n-octyl alcohol.

Standard co gas: purity 99. 9%.Argon gas: purity.99. 9%

Apparatus and equipment

Gas chromatography(equipped withFID and methanizer).High speed blender.

Centrifuge:4 000 r'min.

Gas-tight syringe: 10 μL,50 μL.1 mL.Head-space bottle: 1ao mL

Procedure

Calibration CO gas

CO standard gas series

Filled the purity cO into the 1o0 mL Head-space bottle at the normal atmospheric pressire.and closed$N/T2052—2008

as quickly as possible with a cap which was placed a septum and an O-ring. In the same way filled six100 mL Heacd-space bottles with argon gas,and then inject 99. 9%CO 50 μL.100 μL.200 μL.300 μL.500 L、1D00 μL into them. The CO standard gas series are 0.5 L/mL、1.0 μxL/mL、2. μL/mL、3. 0 rL/rmiL,5. 0 jxL/rriL,10. 0 μxL/mL CO.3.4.1.2co gas calibration seriesIn six 100 mL Head-space bottles,55 mL water.0, 25 mL n-octyl alcolol.20 mL 20% ( V/ V)Sulfateacid solution were added.and they were closed tightly. 1 mL the leadspace gas of these bottles wasdrawn anc then injected separately the Co standard gas series. The mixtures were shaked vigorouslyfor about 1 min.and left for 1 h. 1.0 mL of the head-space gas was taken and injected into the gaschromatograph. According to the response area and the concentration of co.the Co gas calibrationcurve could be obtainecd.

Preparation af test sample and extractionWeigh ca 100 g of the test sample (accurate to 0. 1 g). Sample was miriced.added 200 mL water,ho-mogenized for 1 min in a iced-bath.arid ceritrifuge for 10 min at 4 000 r/min (10'c ). The supernatant,50 mL.was poured into a 100 mL head-space bottle,then 5 mL of water.20 mL 20% ( V/ V) Sulfateacid soluition:0. 25 mL n-octyl alcohal were added. A cap with a septurn and an O-ring was placed onthe bottle: which was closed as quickly as possible. The mixtures were shaked vigorouisly for about2 min.and lelt [or 1 h. 1. d mL ol the head-space gas was taken anc iniected into the gas chramato-graph.

3. 4, 3 Determination

GC operating conditions

Column: Caronxen M 1 00s PLOT,30 m × 530 μmti. d. ).or the equivalent :a

Detector:FID;

Column temperature:50'C :

Injection port temperatuire: 10o' :d

Detector temperatuire:200c ;e)

Methanizer temperature:375'cf)

Carrier gas:N, (purity::99. 99 % ).15 mL/min: H. :40 mL/rrin: Air: 450 rriL/min1;g

h)Injectian mode:head-space;co

i) Injection volume:1 mL.

3. 4. 3.2 GC operating

S>/T2052—2008

According to the CO gas calibration curve,cO residue in flesh could he detected, Under the above Gcoperating condition.the retention time of cO was ahaut 1, 195 min, The chromatograms of the stand-ard see Figure A. 1 in annex AEvery sample should be dauble tested.and the resuilt was mean value.3. 5Calculation and expression af resultCalculation the content of CO residue in thre test sample by GC data processor or according to the formula (1)V

X = 1. 165 × A ×

×1000

theresiduecontentafco inthetestsample.fg/kg:x

A-the concentrationof co inthe test solution from Co gas calibration curveμLV-the voluime of gas in the head-space bottle.mL;yInjection volume.mL:

1.165the density of 1 moL cO at the normal atmaspheric pressuire(20'cC):mg/mL;16. 67-mass of test sample of final sarnple solution.g.4 Limit of quantilalion( LOQ) and recovery4. 1 Limit of quantitation

The limit of quantitation (LoQ) of the method is 5a μg.kg4.2Recovery

According to the experimental data.the fortifying coriceritrations of test sarriple and its correspond.ing recaveries in tuna,tilapia and red salmon are as follows:a)

Fortirying concentrations was 50 μrg: kg : The recoveries were between 69. 6% ~-84. 8% ;Forti[ying concentrations was 21D μg/kg.The recoveries were between 82.4% ~103.8% :Fortifyirig concentrations was 699 pμg/ kg. The recoveries were between 86. 1% ~103. 2% :b)Tilapia:

Fortifying concentrations was 50 μg/kg.The recoveries were between 64. 4% 80.2% ;$N/T 2052—2008

Fortifying concentrations was 210 μg. kg, The recoveries were between 73. 6% ~96. 9% ;Fortifying concentrations was 699 μg/kg-The recoveries were between 69.7% -- 101. 2% :C

Red salmon:

Fortilying concentrations was 50 μg: kg : The recoveries were between 65. 8% ~81. a% :Fortifyirig concentrations was 210 μg/ kg, The recoveries were betweeri 74. 8% ~104. 8% :Fortifying conceritrations was 699 μg/ kg, The recoveries were between 75. 2% ~95. 4%

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

标准图片预览:

- 热门标准

- 商检行业标准(SN)

- SN/T2404-2009 玩具中防腐剂2-甲基-4-异噻唑啉-3-酮及其衍生物的测定

- SN/T2004.2-2005 电子电气产品中铅、镉、铬的测定 第2部分:火焰原子吸收光谱法

- SN/T2648-2010 进出口食品中啶酰菌胺残留量的测定 气相色谱-质谱法

- SN/T2927-2011 出口水处理用无烟煤滤料检验规程

- SN/T3591-2013 实验室标准物质管理指南

- SN/T3764-2013 猕猴桃举肢蛾检疫鉴定方法

- SN/T4081-2014 伤残短体线虫检疫鉴定方法

- SN/T1349-2004 山松大小蠹检疫鉴定方法

- SN/T1667.2-2007 进出口机电产品检测方法 第2部分:彩色液晶显示器件电光性能的测量

- SN/T1743-2006 食品中诱惑红、酸件红、亮蓝、日落黄的含量检测高效液相色谱法

- SN/T2329-2009 化妆品眼刺激性/腐蚀性的鸡胚绒毛尿囊试验

- SN/T2870-2011 中肠腺坏死杆状病毒病检疫技术规范

- SN/T1589.7-2013 进出口家用和类似用途电器检验规程 第7部分:空气净化器

- SN/T1603.1-2012 进出口音视频及类似电子设备检验规程 第1部分:通用要求

- SN/T0739-1997 出口热镀锌焊接薄壁钢管检验规程

- 行业新闻

请牢记:“bzxz.net”即是“标准下载”四个汉字汉语拼音首字母与国际顶级域名“.net”的组合。 ©2025 标准下载网 www.bzxz.net 本站邮件:bzxznet@163.com

网站备案号:湘ICP备2025141790号-2

网站备案号:湘ICP备2025141790号-2