- 您的位置:

- 标准下载网 >>

- 标准分类 >>

- 商检行业标准(SN) >>

- SN/T 1594-2005 进出口茶叶中噻嗪酮残留量检验方法 气相色谱法(附英文版)

标准号:

SN/T 1594-2005

标准名称:

进出口茶叶中噻嗪酮残留量检验方法 气相色谱法(附英文版)

标准类别:

商检行业标准(SN)

标准状态:

现行-

发布日期:

2005-05-20 -

实施日期:

2005-12-01 出版语种:

简体中文下载格式:

.rar.pdf下载大小:

243.07 KB

点击下载

标准简介:

标准下载解压密码:www.bzxz.net

本标准规定了进出口茶叶中噻嗪酮残留量检验的抽样、制样和气相色谱测定方法。本标准适用于进出口茶叶中噻嗪酮残留量的检验。 SN/T 1594-2005 进出口茶叶中噻嗪酮残留量检验方法 气相色谱法(附英文版) SN/T1594-2005

部分标准内容:

中华人民共和国出入境检验检疫行业标准SN/T1594—2005

进出口茶叶中噻嗪酮残留量检验方法气相色谱法

Inspection of buprofezin residue in tea for import and export-Gas chromatographic method

2005-05-20发布

中华人民共和国

数码防伪

国家质量监督检验检疫总局免费标准下载网bzxz

2005-12-01实施

本标准的附录A为资料性附录。

本标准由国家认证认可监督管理委员会提出并归口。本标准起草单位:中华人民共和国浙江出人境检验检疫局。本标准主要起草人:丁慧瑛、朱晓雨、谢文、章晓氨、朱青青。本标准系首次发布的出入境检验检疫行业标准。SN/T1594—2005

1范围

进出口茶叶中噻嗪酮残留量检验方法气相色谱法

SN/T1594—2005

本标准规定了进出口茶叶中噻嗪酮残留量检验的抽样、制样和气相色谱测定方法。本标准适用于进出口茶叶中噻嗪酮残留量的检验。2抽样和制样

2.1检验批

以不超过2000件为一检验批。同一检验批的商品应具有同一特征,如包装、标记、产地、规格、等级等。

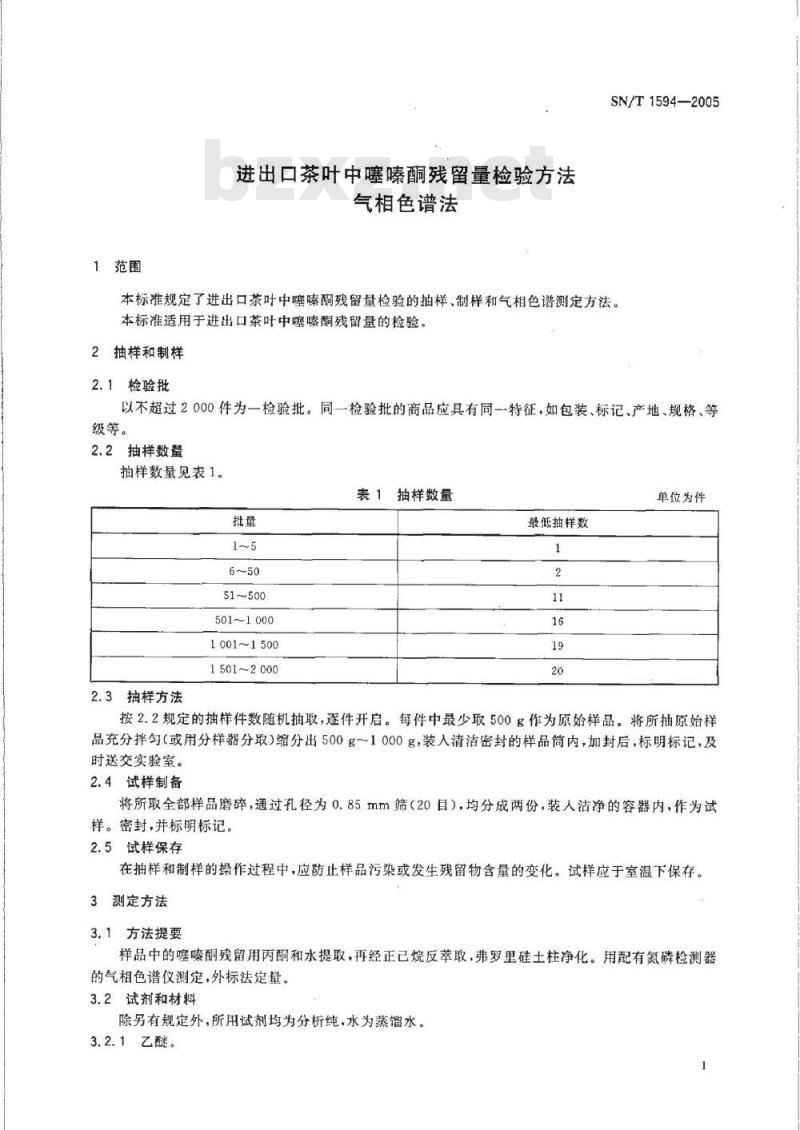

2.2抽样数量

抽样数量见表1。

表1抽样数量

51~500

501~1000

1001~1500

1501~2000

2.3抽样方法

最低抽样数

单位为件

按2.2规定的抽样件数随机抽取,逐件开启。每件中最少取500g作为原始样品。将所抽原始样品充分拌匀(或用分样器分取)缩分出500g1000g,装人清洁密封的样品简内,加封后,标明标记,及时送交实验室。

2.4试样制备

将所取全部样品磨碎,通过孔径为0.85mm筛(20目),均分成两份,装入洁净的容器内,作为试样。密封,并标明标记。

2.5试样保存

在抽样和制样的操作过程中,应防止样品污染或发生残留物含量的变化。试样应于室温下保存。3测定方法

3.1方法提要

样品中的噻嗪酮残留用丙酮和水提取,再经正己烷反萃取,弗罗里硅土柱净化。用配有氮磷检测器的气相色谱仪测定,外标法定量。3.2试剂和材料

除另有规定外,所用试剂均为分析纯,水为蒸馏水。3.2.1乙醚。

SN/T1594—2005

正已烷。

3.2.3丙酮。

3.2.4氯化钠水溶液150g/L。

3.2.5洗脱液:正已烷-乙醚(7+3)3.2.6无水硫酸钠:650℃灼烧4h,在干燥器内冷却至室温,贮于密封瓶中备用。3.2.7弗罗里硅±:粒度0.075mm~0.15mm(100目~200日)。650℃灼烧4h,使用前一天于130℃活化4h,在干燥器内冷却至室温,加1%的水脱活,备用。3.2.8脱脂棉。

3.2.9噻嗪酮标准品:纯度大于99%。3.2.10噻嗪酮标准储备溶液:称取0.01000g噻嗪酮标准品(3.2.9),用正已烷溶解定容至100mL,此溶液浓度为100μg/mL。存放在4℃的冰箱中。根据需要用正已烷稀释至适当浓度的标准工作液。3.3仪器和设备

3.3.1气相色谱仪,配有氮磷检测器。3.3.2旋转蒸发器。

3.3.3均质器。

3.3.4无水硫酸钠柱:80mm×40mm(内径)筒型漏斗,底部垫约5mm高脱脂棉,再装约50mm高无水硫酸钠。

3.3.5净化柱:200mmX15mm(内径)玻璃柱,底部垫约5mm高脱脂棉和约20mm高无水硫酸钠,10g弗罗里硅土,顶端加约20mm高无水硫酸钠,使用前用30mL正已烷淋洗。3.4测定步骤

3.4.1提取

称取5g试样(精确到0.01g)置于100mL烧杯中,加入15mL蒸馏水浸泡2h,加人30mL丙酮,在均质器中均质2min。过滤至50mL容量瓶中,用丙酮清洗残渣,合并滤液,并定容至50mL。移取20.0mL滤液至预先装有50mL氯化钠水溶液(3.2.4)和25mL正烷的250mL分液漏斗中,剧烈振摇,静置分层。水相中再加入25mL正已烷,重复操作,合并正已烷相;过无水硫酸钠柱(3.3.4)至浓缩瓶中,用旋转蒸发器在45℃水浴减压浓缩至近干。3.4.2净化

浓缩瓶中残留物用2mL、2mL正已烷溶解洗涤2次,将溶液移入净化柱中(3.3.5),用100mL洗脱液(3.2.5)洗脱。收集全部洗脱液,用旋转蒸发器在45℃水浴减压浓缩至近干,加入2.0mL正已烷溶解,供气相色谱测定。

3.4.3测定

3.4.3.1色谱条件

进行测定色谱条件如下:

a)色谱柱:石英毛细管柱,HP-Ultra225m×0.32mm(直径)×0.52μm(膜厚),固定相为:(5%)二苯基-(95%)二甲基硅氧烷共聚物,或相当者;载气和尾吹气:氮气(纯度大于99.999%),载气流量:5.0mL/min,尾吹气流量:20mL/min,b)

空气流量:110mL/min;氢气流量:3.5mL/min;柱温:初始温度70℃保持1min,以25℃/min升至280℃,保持8minc)

d)进样口温度:250℃;

检测器温度:300℃;

开阀时间:1min;

进样方式:不分流进样;

进样量:2μL:

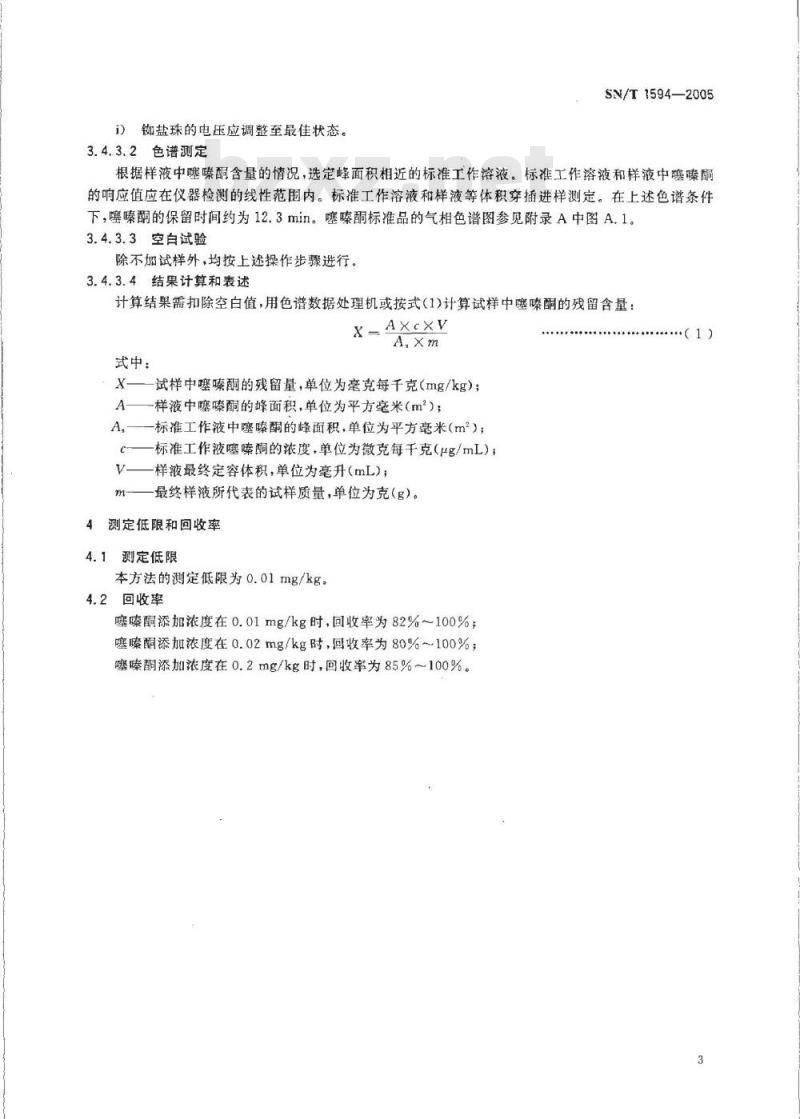

i)盐珠的电压应调整至最佳状态。3.4.3.2色谱测定

SN/T1594—2005

根据样液中噻嗪酮含量的情况,选定峰面积相近的标准工作溶液。标准工作溶液和样液中噻嗪酮的响应值应在仪器检测的线性范围内。标准工作溶液和样液等体积穿插进样测定。在上述色谱条件下,噻嗪酮的保留时间约为12.3min。噻嗪酮标准品的气相色谱图参见附录A中图A.1。3.4.3.3空白试验

除不加试样外,均按上述操作步骤进行。3.4.3.4结果计算和表述

计算结果需扣除空白值,用色谱数据处理机或按式(1)计算试样中噻嗪酮的残留含量:X-AXcXV

式中:

一试样中噻嗪酮的残留量,单位为毫克每千克(mg/kg);一样液中噻嗪酮的峰面积,单位为平方毫米(m);A,——标准工作液中噻嗪酮的峰面积,单位为平方毫米(m);C

标准工作液噻嗪酮的浓度,单位为微克每千克(μg/mL);V—样液最终定容体积,单位为毫升(mL);m

最终样液所代表的试样质量,单位为克(g)。4测定低限和回收率

4.1测定低限

本方法的测定低限为0.01mg/kg。4.2回收率

噻嗪酮添加浓度在0.01mg/kg时,回收率为82%100%;噻嗪酮添加浓度在0.02mg/kg时,回收率为80%~100%;噻嗪酮添加浓度在0.2mg/kg时,回收率为85%100%。(1)

SN/T1594—-2005

附录A

(资料性附录)

标准品色谱图

噻嗪酮

噻嗪酮标准品气相色谱图

Fr/min

Foreword

AnnexAof this standard isan informativeannex.SN/T1594—2005

This standard was proposed by and is under the charged of The Certification and Accreditation Ad.ministration of the People's Republic of China.This standard was drafted by Zhejiang Entry-Exit Inspection and Quarantine Bureau.The standard was mainly drafted by Ding Huiying, Zhu Xiao yu, Xie Wen,Zhang Xiao Dong and ZhuQing Qing.

This standard is a professional standard for entry-exit inspection and quarantine promulgated for thefirst time.

SN/T1594—2005

Inspection of buprofezinresidue inteaforexportand import-Gaschromatographicmethod

1Scope

This standard specifies the methods of sampling, sample reparation and determination by gas chro-matography(Gc)of buprofezin residue inteaforexport and importThis standard is applicable to the determination of buprofezin residues in tea for export and importSampling and sample preparation.2Samplingandsamplepreparation2.1 Inspection lot

Each inspection lot should not be exceed 2 000 packages.The characteristics of the cargowithin the same inspection lot,such as packing,mark,origin,speci-fication and grade etc. should be the same.2.2Quantity of sampletaken

Quantityofsampletaken(seeTable1.Table1

Number of packages in an inspection lot1~5

51~500

501~1000

1001~1500

1501~2000

2.3Samplingprocedure

Minimumnumberofpackagestobetaken,

Draw a number of packagesspecified in 2.2 are taken at random and open the packages. The feastsample weight as the primary sample from each package should be at 5oo g. The combine primarysample is fullymixed,reducedto500-1000 g,placed in a clean sample canister,sealed,labeled andsent to laboratory in time.

2.4 Preparation of test sampleThemixed primary sample is crushed with a grinder or mortar until throughly crushed and wholly6

SN/T1594—2005

passed through a 0.85 mm(id) sieve(20 mesh),and then divided into two equal portions.Each por-tion is placed in a clean container as the test sample, which is then sealed and labeled.2.5 Storage of test sample

In the course of sampling and sample preparation.precautions mustbe taken toavoid contaminationor any factors which may cause the change of residue content. The test samples should be stored atroomtemperature

3Method ofdetermination

3.1Principle

Buprofezin residue are extracted from the tea sample by acetone,and re-extracted by hexane,andcleaned up by passing through a florisil column. The solution is used for GC-NPD determination. Ex-ternal standard method is used for quantitativemeasurement.3.2Reagentsandmaterials

Unless otherwise specified,all the reagent used should be analytical.grade,\water\ is distilled wa-ter.

ethyl ether.

n-hexane

Sodiumchloridesolution150g/L.Eluting solution:n-hexane-ethyl ether(7+3)3.2.6Anhydrous sodium sulfate: ignite for 4 h at 650℃, and keep in a tightly closed container.3.2.7Florisil:granulesize0.075mm~0.15mm(100mesh~200mesh),ignitefor4hat650℃,and keep in a tightly closed container,then heat for 4 h at 13oc in an oven, cooling to room temper-ature in desiccator and add 1% of water before use.3.2.8

Absorbentcotton.

Satandardofbuprofezin:purity>99%.3.2.10Stock satandard solution of buprofezin:accurately weight 0.010 00 g Satandard(3.2.9),dissolve with n-hexane and quantitatively on 100 mL, the concentration of solution is 100 μg/mL.The solution shall be stored in 4' refrigeratory. According to the requirement, is prepared from the7

SN/T1594-—2005

stock standard solution by n-hexane and diluted to the required concentration.3.3Apparatus andequipment

Gaschromatography,equippedwithNitrogenphosphorusdetectorRotaryvacuumevaporator

High speed blender.

Column of anhydrous sodium sulfate: 80 mm × 40 mm(id) cylinder funnel, pack with ca5mmabsorbent cotton at thebottomof thecolumn and fill in50mmanhydroussodium sulfate.3.3.5Columnforclean-up:200mmx15mm(id)glasscloumn,packwith5mmabsorbentcottonat the bottom of the column and fill in 20 mm anhydrous sodium sulfate, 10 g florisil, fill in 20 mmanhydrous sodium suifate at top.Add 30 mL of n-hexane wash before use.3.4Procedure

Extraction

Weigh ca5g of the test sample(accurate to 0.01g)into a 100mLbeaker.Add 15rnL waterandstand to 2 hours.Add 30 mL acetone , mixed 2 min in high speed blender,filter the extracted solu-tion with a filter paper,collect the filtrates quantitatively in 50 mL volunetric flask with acetone.Transfer20.0mL filter solution intoa250mL separatoryfunnel which isadded 50mLsodium chlo-ride solution(3.2.4)and 25mL n-hexane,shakevigorouslyfor2min,let standtoseparating,Add 25mL n-hexane to water layer, repeat the operation again.Combine the n-hexane layers through col-umn of anhydrous sodium sulfate(3.3.4) into a 1o0 mL round bottom flask to nearly dryness at rota-ryvacuumevaporatorbleow45℃

Cleanup

Add 2 mL n-hexane and 2 mL n-hexane to dissolve the residue, transfer the above solution into col-umn(3.3.5),eluted with 100 mL eluting solution(3.2.5).Collect all the eluted solution and rotaryvacuum evaporate to dryness below 45℃.Add exactly2.O mL n-hexane to dissolve the residue,the solution is ready for GC determination.3.4.3

Determination

G operating condition

Chromatographiccolumn:Fused silica capillarycolumn,Ultra225m×0.32mm(id)×0.52μm(filmthickness),composition:5%diphenyland95%dimethylpolysiloxane;b)

Carrier gas and make-up gas:Nitrogoen(purity>99.999%),Flow rate of carrier gas:5.0mL/min,flowrateofmake-upgas:20mL/min,flowrateofhydrogen:3.5mL/min,flowrateofair110mL/min;

SN/T1594—2005

Temperatureprogramme:70℃(keep1min),25℃/minto280(keep8min);Injectionporttemperature:25o℃;Detector temperature:30o℃;

Purgevalve:1min on;

Inectionmode:Splitless;

Injectionvolume:2μL;

i)The voltage of the bead should be adjusted good condition,GC determination

According to the concentrations of buprofezin, select the standard working solution with similarpeak area to that of sample solution. The responses of buprofezin in the standard working solutionand the sample solution should be within the linear range of the instrumental detection. The standardworking solution should be randomly injected in between the injections of sample solution of egualvolume. Under the above Gc operating condition, the retention time of buprofezin is about12.3min.For chromatogram of the standard seeFigureA.1 in annexA.3.4.3.3Blank test

The operation of the blank test is the same as the described in the method of determination, but withtheomission of sampleaddition.3.4.3.4Calculation and expression of resultThe blank value should be subtracted from the above result of calculation. calculation the content ofbuprofezin residue in the test sampleby GC data processororaccording to the formula(1):X

-theresidue content of buprofezin in the test sample,mg/kg;thepeakareaofbuprofezinin samplesolution,m';-thepeakareaof-multi organophosphorus instandardworkingsolution,mC-the concentration of multi organophosphorus in working solution,μg/mt;V

-the final volume of the sample solution,mL;Massoftest sample,g.

4 Limit of determination and recovery4.1 Limit of determination

The limit of determination of this method is O.D1 mg /kg.4.2Recovery

buprofezin0.01mg/kg,the recovery is82%~100%buprofezin0.02mg/kg,therecoveryis80%~100%;buprofezin0.2mg/kg,therecoveryis85%~100%(1)

SN/T 1594—2005

AnnexA

(informative)

Chromatogram of the standardBuprofezin

Fig.A.1 Gas chromatogram of buprofezintr/mint

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

进出口茶叶中噻嗪酮残留量检验方法气相色谱法

Inspection of buprofezin residue in tea for import and export-Gas chromatographic method

2005-05-20发布

中华人民共和国

数码防伪

国家质量监督检验检疫总局免费标准下载网bzxz

2005-12-01实施

本标准的附录A为资料性附录。

本标准由国家认证认可监督管理委员会提出并归口。本标准起草单位:中华人民共和国浙江出人境检验检疫局。本标准主要起草人:丁慧瑛、朱晓雨、谢文、章晓氨、朱青青。本标准系首次发布的出入境检验检疫行业标准。SN/T1594—2005

1范围

进出口茶叶中噻嗪酮残留量检验方法气相色谱法

SN/T1594—2005

本标准规定了进出口茶叶中噻嗪酮残留量检验的抽样、制样和气相色谱测定方法。本标准适用于进出口茶叶中噻嗪酮残留量的检验。2抽样和制样

2.1检验批

以不超过2000件为一检验批。同一检验批的商品应具有同一特征,如包装、标记、产地、规格、等级等。

2.2抽样数量

抽样数量见表1。

表1抽样数量

51~500

501~1000

1001~1500

1501~2000

2.3抽样方法

最低抽样数

单位为件

按2.2规定的抽样件数随机抽取,逐件开启。每件中最少取500g作为原始样品。将所抽原始样品充分拌匀(或用分样器分取)缩分出500g1000g,装人清洁密封的样品简内,加封后,标明标记,及时送交实验室。

2.4试样制备

将所取全部样品磨碎,通过孔径为0.85mm筛(20目),均分成两份,装入洁净的容器内,作为试样。密封,并标明标记。

2.5试样保存

在抽样和制样的操作过程中,应防止样品污染或发生残留物含量的变化。试样应于室温下保存。3测定方法

3.1方法提要

样品中的噻嗪酮残留用丙酮和水提取,再经正己烷反萃取,弗罗里硅土柱净化。用配有氮磷检测器的气相色谱仪测定,外标法定量。3.2试剂和材料

除另有规定外,所用试剂均为分析纯,水为蒸馏水。3.2.1乙醚。

SN/T1594—2005

正已烷。

3.2.3丙酮。

3.2.4氯化钠水溶液150g/L。

3.2.5洗脱液:正已烷-乙醚(7+3)3.2.6无水硫酸钠:650℃灼烧4h,在干燥器内冷却至室温,贮于密封瓶中备用。3.2.7弗罗里硅±:粒度0.075mm~0.15mm(100目~200日)。650℃灼烧4h,使用前一天于130℃活化4h,在干燥器内冷却至室温,加1%的水脱活,备用。3.2.8脱脂棉。

3.2.9噻嗪酮标准品:纯度大于99%。3.2.10噻嗪酮标准储备溶液:称取0.01000g噻嗪酮标准品(3.2.9),用正已烷溶解定容至100mL,此溶液浓度为100μg/mL。存放在4℃的冰箱中。根据需要用正已烷稀释至适当浓度的标准工作液。3.3仪器和设备

3.3.1气相色谱仪,配有氮磷检测器。3.3.2旋转蒸发器。

3.3.3均质器。

3.3.4无水硫酸钠柱:80mm×40mm(内径)筒型漏斗,底部垫约5mm高脱脂棉,再装约50mm高无水硫酸钠。

3.3.5净化柱:200mmX15mm(内径)玻璃柱,底部垫约5mm高脱脂棉和约20mm高无水硫酸钠,10g弗罗里硅土,顶端加约20mm高无水硫酸钠,使用前用30mL正已烷淋洗。3.4测定步骤

3.4.1提取

称取5g试样(精确到0.01g)置于100mL烧杯中,加入15mL蒸馏水浸泡2h,加人30mL丙酮,在均质器中均质2min。过滤至50mL容量瓶中,用丙酮清洗残渣,合并滤液,并定容至50mL。移取20.0mL滤液至预先装有50mL氯化钠水溶液(3.2.4)和25mL正烷的250mL分液漏斗中,剧烈振摇,静置分层。水相中再加入25mL正已烷,重复操作,合并正已烷相;过无水硫酸钠柱(3.3.4)至浓缩瓶中,用旋转蒸发器在45℃水浴减压浓缩至近干。3.4.2净化

浓缩瓶中残留物用2mL、2mL正已烷溶解洗涤2次,将溶液移入净化柱中(3.3.5),用100mL洗脱液(3.2.5)洗脱。收集全部洗脱液,用旋转蒸发器在45℃水浴减压浓缩至近干,加入2.0mL正已烷溶解,供气相色谱测定。

3.4.3测定

3.4.3.1色谱条件

进行测定色谱条件如下:

a)色谱柱:石英毛细管柱,HP-Ultra225m×0.32mm(直径)×0.52μm(膜厚),固定相为:(5%)二苯基-(95%)二甲基硅氧烷共聚物,或相当者;载气和尾吹气:氮气(纯度大于99.999%),载气流量:5.0mL/min,尾吹气流量:20mL/min,b)

空气流量:110mL/min;氢气流量:3.5mL/min;柱温:初始温度70℃保持1min,以25℃/min升至280℃,保持8minc)

d)进样口温度:250℃;

检测器温度:300℃;

开阀时间:1min;

进样方式:不分流进样;

进样量:2μL:

i)盐珠的电压应调整至最佳状态。3.4.3.2色谱测定

SN/T1594—2005

根据样液中噻嗪酮含量的情况,选定峰面积相近的标准工作溶液。标准工作溶液和样液中噻嗪酮的响应值应在仪器检测的线性范围内。标准工作溶液和样液等体积穿插进样测定。在上述色谱条件下,噻嗪酮的保留时间约为12.3min。噻嗪酮标准品的气相色谱图参见附录A中图A.1。3.4.3.3空白试验

除不加试样外,均按上述操作步骤进行。3.4.3.4结果计算和表述

计算结果需扣除空白值,用色谱数据处理机或按式(1)计算试样中噻嗪酮的残留含量:X-AXcXV

式中:

一试样中噻嗪酮的残留量,单位为毫克每千克(mg/kg);一样液中噻嗪酮的峰面积,单位为平方毫米(m);A,——标准工作液中噻嗪酮的峰面积,单位为平方毫米(m);C

标准工作液噻嗪酮的浓度,单位为微克每千克(μg/mL);V—样液最终定容体积,单位为毫升(mL);m

最终样液所代表的试样质量,单位为克(g)。4测定低限和回收率

4.1测定低限

本方法的测定低限为0.01mg/kg。4.2回收率

噻嗪酮添加浓度在0.01mg/kg时,回收率为82%100%;噻嗪酮添加浓度在0.02mg/kg时,回收率为80%~100%;噻嗪酮添加浓度在0.2mg/kg时,回收率为85%100%。(1)

SN/T1594—-2005

附录A

(资料性附录)

标准品色谱图

噻嗪酮

噻嗪酮标准品气相色谱图

Fr/min

Foreword

AnnexAof this standard isan informativeannex.SN/T1594—2005

This standard was proposed by and is under the charged of The Certification and Accreditation Ad.ministration of the People's Republic of China.This standard was drafted by Zhejiang Entry-Exit Inspection and Quarantine Bureau.The standard was mainly drafted by Ding Huiying, Zhu Xiao yu, Xie Wen,Zhang Xiao Dong and ZhuQing Qing.

This standard is a professional standard for entry-exit inspection and quarantine promulgated for thefirst time.

SN/T1594—2005

Inspection of buprofezinresidue inteaforexportand import-Gaschromatographicmethod

1Scope

This standard specifies the methods of sampling, sample reparation and determination by gas chro-matography(Gc)of buprofezin residue inteaforexport and importThis standard is applicable to the determination of buprofezin residues in tea for export and importSampling and sample preparation.2Samplingandsamplepreparation2.1 Inspection lot

Each inspection lot should not be exceed 2 000 packages.The characteristics of the cargowithin the same inspection lot,such as packing,mark,origin,speci-fication and grade etc. should be the same.2.2Quantity of sampletaken

Quantityofsampletaken(seeTable1.Table1

Number of packages in an inspection lot1~5

51~500

501~1000

1001~1500

1501~2000

2.3Samplingprocedure

Minimumnumberofpackagestobetaken,

Draw a number of packagesspecified in 2.2 are taken at random and open the packages. The feastsample weight as the primary sample from each package should be at 5oo g. The combine primarysample is fullymixed,reducedto500-1000 g,placed in a clean sample canister,sealed,labeled andsent to laboratory in time.

2.4 Preparation of test sampleThemixed primary sample is crushed with a grinder or mortar until throughly crushed and wholly6

SN/T1594—2005

passed through a 0.85 mm(id) sieve(20 mesh),and then divided into two equal portions.Each por-tion is placed in a clean container as the test sample, which is then sealed and labeled.2.5 Storage of test sample

In the course of sampling and sample preparation.precautions mustbe taken toavoid contaminationor any factors which may cause the change of residue content. The test samples should be stored atroomtemperature

3Method ofdetermination

3.1Principle

Buprofezin residue are extracted from the tea sample by acetone,and re-extracted by hexane,andcleaned up by passing through a florisil column. The solution is used for GC-NPD determination. Ex-ternal standard method is used for quantitativemeasurement.3.2Reagentsandmaterials

Unless otherwise specified,all the reagent used should be analytical.grade,\water\ is distilled wa-ter.

ethyl ether.

n-hexane

Sodiumchloridesolution150g/L.Eluting solution:n-hexane-ethyl ether(7+3)3.2.6Anhydrous sodium sulfate: ignite for 4 h at 650℃, and keep in a tightly closed container.3.2.7Florisil:granulesize0.075mm~0.15mm(100mesh~200mesh),ignitefor4hat650℃,and keep in a tightly closed container,then heat for 4 h at 13oc in an oven, cooling to room temper-ature in desiccator and add 1% of water before use.3.2.8

Absorbentcotton.

Satandardofbuprofezin:purity>99%.3.2.10Stock satandard solution of buprofezin:accurately weight 0.010 00 g Satandard(3.2.9),dissolve with n-hexane and quantitatively on 100 mL, the concentration of solution is 100 μg/mL.The solution shall be stored in 4' refrigeratory. According to the requirement, is prepared from the7

SN/T1594-—2005

stock standard solution by n-hexane and diluted to the required concentration.3.3Apparatus andequipment

Gaschromatography,equippedwithNitrogenphosphorusdetectorRotaryvacuumevaporator

High speed blender.

Column of anhydrous sodium sulfate: 80 mm × 40 mm(id) cylinder funnel, pack with ca5mmabsorbent cotton at thebottomof thecolumn and fill in50mmanhydroussodium sulfate.3.3.5Columnforclean-up:200mmx15mm(id)glasscloumn,packwith5mmabsorbentcottonat the bottom of the column and fill in 20 mm anhydrous sodium sulfate, 10 g florisil, fill in 20 mmanhydrous sodium suifate at top.Add 30 mL of n-hexane wash before use.3.4Procedure

Extraction

Weigh ca5g of the test sample(accurate to 0.01g)into a 100mLbeaker.Add 15rnL waterandstand to 2 hours.Add 30 mL acetone , mixed 2 min in high speed blender,filter the extracted solu-tion with a filter paper,collect the filtrates quantitatively in 50 mL volunetric flask with acetone.Transfer20.0mL filter solution intoa250mL separatoryfunnel which isadded 50mLsodium chlo-ride solution(3.2.4)and 25mL n-hexane,shakevigorouslyfor2min,let standtoseparating,Add 25mL n-hexane to water layer, repeat the operation again.Combine the n-hexane layers through col-umn of anhydrous sodium sulfate(3.3.4) into a 1o0 mL round bottom flask to nearly dryness at rota-ryvacuumevaporatorbleow45℃

Cleanup

Add 2 mL n-hexane and 2 mL n-hexane to dissolve the residue, transfer the above solution into col-umn(3.3.5),eluted with 100 mL eluting solution(3.2.5).Collect all the eluted solution and rotaryvacuum evaporate to dryness below 45℃.Add exactly2.O mL n-hexane to dissolve the residue,the solution is ready for GC determination.3.4.3

Determination

G operating condition

Chromatographiccolumn:Fused silica capillarycolumn,Ultra225m×0.32mm(id)×0.52μm(filmthickness),composition:5%diphenyland95%dimethylpolysiloxane;b)

Carrier gas and make-up gas:Nitrogoen(purity>99.999%),Flow rate of carrier gas:5.0mL/min,flowrateofmake-upgas:20mL/min,flowrateofhydrogen:3.5mL/min,flowrateofair110mL/min;

SN/T1594—2005

Temperatureprogramme:70℃(keep1min),25℃/minto280(keep8min);Injectionporttemperature:25o℃;Detector temperature:30o℃;

Purgevalve:1min on;

Inectionmode:Splitless;

Injectionvolume:2μL;

i)The voltage of the bead should be adjusted good condition,GC determination

According to the concentrations of buprofezin, select the standard working solution with similarpeak area to that of sample solution. The responses of buprofezin in the standard working solutionand the sample solution should be within the linear range of the instrumental detection. The standardworking solution should be randomly injected in between the injections of sample solution of egualvolume. Under the above Gc operating condition, the retention time of buprofezin is about12.3min.For chromatogram of the standard seeFigureA.1 in annexA.3.4.3.3Blank test

The operation of the blank test is the same as the described in the method of determination, but withtheomission of sampleaddition.3.4.3.4Calculation and expression of resultThe blank value should be subtracted from the above result of calculation. calculation the content ofbuprofezin residue in the test sampleby GC data processororaccording to the formula(1):X

-theresidue content of buprofezin in the test sample,mg/kg;thepeakareaofbuprofezinin samplesolution,m';-thepeakareaof-multi organophosphorus instandardworkingsolution,mC-the concentration of multi organophosphorus in working solution,μg/mt;V

-the final volume of the sample solution,mL;Massoftest sample,g.

4 Limit of determination and recovery4.1 Limit of determination

The limit of determination of this method is O.D1 mg /kg.4.2Recovery

buprofezin0.01mg/kg,the recovery is82%~100%buprofezin0.02mg/kg,therecoveryis80%~100%;buprofezin0.2mg/kg,therecoveryis85%~100%(1)

SN/T 1594—2005

AnnexA

(informative)

Chromatogram of the standardBuprofezin

Fig.A.1 Gas chromatogram of buprofezintr/mint

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

标准图片预览:

- 热门标准

- 商检行业标准(SN)

- SN/T4322-2015 食品接触材料高分子材料双酚A残留量的测定酶联免疫法

- SN0667-1997 出口肉及肉制品中丙酸睾丸酮残留量检验方法放射免疫法

- SN/T3756-2013 玉米细菌性枯萎病菌检疫鉴定方法PCR方法

- SN/T0944-2000 出口冻虾及虾制品中吲哚检验方法比色法

- SN/T0794-1999 进出口西洋参检验规程

- SN/T1891.10-2007 进出口微波食品包装容器及包装材料卫生标准 第10部分:聚苯乙烯树脂

- SN/T3534-2013 搪瓷及玻璃器皿中砷、锑溶出量的测定 原子荧光法

- SN/T4773-2017 玩具材料中N-亚硝胺和N-亚硝基化合物迁移量的测定高效液相色谱-串联质谱法

- SN/T4584-2016 出口动物源性食品中沃尼妙林和泰妙菌素残留量的测定液相色谱-质谱/质谱法

- SN0047-1992 出口黄酒检验规程

- SN0069-1992 出口革皮服装检验规程

- SN/T1283-2003 国境口岸结核病监测规程

- SN/T0958-2000 进出口冻蚕蛹检验规程

- SN/T0777-1999 出口冻鱵鱼片检验规程

- SN/T0802.1-1999 进出口磷脂乙醚不溶物检验方法

- 行业新闻

请牢记:“bzxz.net”即是“标准下载”四个汉字汉语拼音首字母与国际顶级域名“.net”的组合。 ©2025 标准下载网 www.bzxz.net 本站邮件:bzxznet@163.com

网站备案号:湘ICP备2025141790号-2

网站备案号:湘ICP备2025141790号-2