- 您的位置:

- 标准下载网 >>

- 标准分类 >>

- 商检行业标准(SN) >>

- SN/T 2063-2008 进出口蜂王浆中氯霉素残留量的检测方法液相色谱串联质谱法

标准号:

SN/T 2063-2008

标准名称:

进出口蜂王浆中氯霉素残留量的检测方法液相色谱串联质谱法

标准类别:

商检行业标准(SN)

标准状态:

现行-

发布日期:

2008-04-29 -

实施日期:

2008-11-01 出版语种:

简体中文下载格式:

.rar.pdf下载大小:

737.39 KB

标准ICS号:

食品技术>>67.050食品试验和分析的一般方法中标分类号:

食品>>食品综合>>X04基础标准与通用方法

部分标准内容:

中华人民共和国出入境检验检疫行业标准SN/T 2063—2008

进出口蜂王浆中氯霉素

残留量的检测方法

液相色谱串联质谱法

Determination of chloramphenicol residue in royajellyfor import and export-LC-MS/MS2008-04-29发布

中华人民共和国

国家质量监督检验检疫总局

2008-11-01实施

本标准的附录A和附录B均为资料性附录。本标准由国家认证认可监督管理委员会提出并归口。本标准起草单位:中华人民共和国浙江出入境检验检疫局。本标准主要起草人:谢文、丁慧瑛、钱艳、昊君阳、陈笑梅、黄雷芳本标准系首次发布的出入境检验检疫行业标准SN/T2063—2008

1范围

进出口蜂王浆中氯霉素

残留量的检测方法

液相色谱串联质谱法

本标准规定了蜂主浆中氯霉素残留量的制样和液相色谱串联质谱测定方法本标准适用于蜂主浆中氯霉素残留量的检测2方法提要

SN/T2063—2008

样品用甲醇沉淀蛋白质,再用乙酸乙酯提取,经硅胶和OasisHLB固相萃取小柱净化,液相色谱串联质谱测定和确证,同位素内标法定量3试剂和材料

除另有规定外,所有试剂均为分析纯,水为二次蒸馏水。3.1乙酸乙酯:高效液相色谱级。3.2甲醇:高效液相色谱级。

3.3甲苯:高效液相色谱级。

3.4氯化钠。

3.5无水硫酸钠:650℃灼烧4h,在干燥器内冷却至室温,贮于密封瓶中备用3.6甲醇水溶液:甲醇-水(2+8.体积比)。3.7甲苯-乙睛(9十1.体积比)。3.8甲苯-乙睛(4十6.体积比)。3.9氯霉素标准品(chloramphenicol.CASNO.56-75-7.CuH12ClzN2O,):纯度大于等于99%。3.10氯霉素-d5标准品:纯度大于等于99%。3.11氯霉素标准储备溶液:称取适量标准品(3.9),用甲醇溶解,溶液浓度为100ug/mL。1℃~4℃冷藏保存。有效期6个月。

3.12氯霉素-d5标准储备溶液:称取适量标准品(3.10).用甲醇溶解,溶液浓度为100μg/mL,1℃~4℃冷藏保存。有效期6个月。

3.13标准工作溶液:根据需要用空白样品溶液将标准储备液稀释成0.04ng/ml、0.12ng/mL、0.24ng/mL、0.32ng/mL、0.64ng/mL的标准工作溶液,相当于样品中含有0.1μg/kg、0.3μg/kg、0.6ug/kg、0.8μg/kg、1.6μg/kg氯霉素,同位素内标氯霉素-d5浓度均为0.25ng/mL。3.14无水硫酸钠柱:80mm×40mm(内径)筒形漏斗,底部垫5mm脱脂棉,再装40mm无水硫酸钠。3.15硅胶固相萃取柱:500mg或相当者,使用前用10mL甲苯-乙(9+1.体积比)预洗。3.16OasisHLB固相萃取柱:500mg,或相当者.使用前用甲醇7mL和水10mL预洗。4仪器和设备

4.1高效液相色谱-串联质谱仪:配有电喷雾离子源。4.2旋转蒸发器

4.3旋涡混合器。

SN/T2063—2008

固相萃取装置。

4.5高速离心机:7000r/min。

4.6氮吹仪。

5试样制备与保存

取500g代表性蜂王浆样品,在室温下解冻,等样品全部融化后搅匀,将试样均分成两份,分别装入样品瓶中,密封,并标明标记。“一份作为试验样,另一份在一18℃保存。在制样的操作过程中,应防止样品污染或发生残留物含量的变化。6测定步骤

6.1提取

称取4g试样(精确到0.01g)置于50mL具塞离心管中,准确加人0.5mL氯霉素-d5(5ng/mL)内标溶液和15mL水,混匀,静置5min,加甲醇至30.0mL,于旋涡混合器上以2000r/min,混匀1min,以6000r/min离心5min,移取15.0mL上层液置于另一个50mL具塞离心管中,加人2g氯化钠和20mL乙酸乙酯,于旋涡混合器上以2000r/min,混勺1min,以4000r/min离心5min,将上层乙酸乙酯过无水硫酸钠柱(3.14)收集于浓缩瓶中,再加入20mL乙酸乙酯,重复上述操作,合并乙酸乙酯提取液.再用5mL乙酸乙酯洗涤无水硫酸钠柱,在40℃以下水浴减压浓缩至近干。6.2净化

用10mL乙睛-甲苯(1十9.体积比)溶液溶解残渣,将溶解液分次转移至硅胶净化柱(3.15)中,弃去流出液,用6mL乙腈-甲苯(6十4,体积比)洗脱,在50℃以下水浴下平缓氮气吹干,加入5mL水溶解残渣,将溶液转移至OasisHLB柱(3.16)中,再用10mL水和5mL甲醇水溶液(3.6)依次洗涤离心管,洗涤液过固相萃取小柱,弃去流出液。在负压下减压抽干,最后用5mL甲醇洗脱,控制流速1mL/min~2mL/min,收集全部洗脱液于10mL离心管中,洗脱液在50℃以下水浴下平缓氮气吹至约2.5mL,用水定容至5.0mL混匀,将溶液通过0.45μm滤膜,供液相色谱-串联质谱仪测定6.3测定

液相色谱串联质谱条件

色谱柱:C柱,5μm,150mm×4.6mm(内径)或相当者;a)

流动相见表1;

流动相梯度洗脱

时间/min

流速:400μL/min;

进样量:20μL;

离子源:电喷雾离子源;

扫描方式:负离子扫描;

检测方式:多反应监测;

甲醇/%

雾化气、气帘气、辅助气、碰撞气均为高纯氮气:使用前应调节各参数使质谱灵敏度达到检测要求,参考条件参见附录A;

SN/T2063—2008

监测离子对(m/z):氯霉素321.0/256.9(定量离子)、321.0/152.0、321.0/194.0、321.0/175.8:氯霉素-d5326.0/157.1。6.3.2液相色谱串联质谱测定

根据试样中被测样液的含量情况,选取待测物的响应值在仪器线性响应范围内的浓度进行测定,如超出仪器线性响应范围应进行稀释。在上述色谱条件下氯每素、氯素-d5的参考保留时间约为6.1min,标准溶液的选择性离子流图参见附录B中图B.1。6.3.3液相色谱串联质谱确证

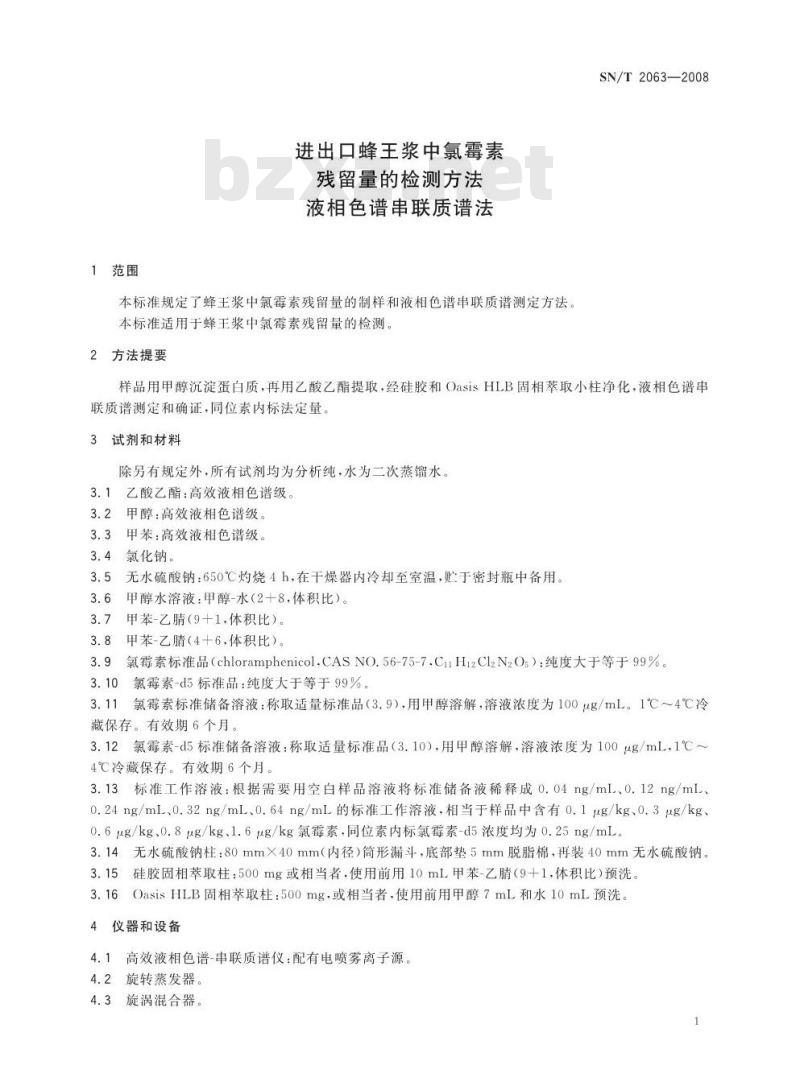

按照液相色谱-串联质谱条件测定样品和标准工作溶液,样品中待测物质的保留时间与标准溶液中待测物质的保留时间偏差在士2.5%之内。定量测定时采用同位素内标标准曲线法。定性时应当与浓度相当标准工作溶液的相对丰度一致,相对丰度允许偏差不超过表2规定的范围,则可判断样品中存在对应的被测物。

表2定性确证时相对离子丰度的最大允许偏差相对离子丰度/%

允许的相对偏差/%

6.3.4空白试验

除不加试样外,均按上述操作步骤进行。7结果计算和表述

>20~50

>10~20

用色谱数据处理机或按下式计算试样中氯霉素残留含量,计算结果需扣除空白值:a=(y-a)/b

b=nZriyr-Eyi/n(a-())

a=(i-ba)/m

式中:

样品中氯霉素的残留量,单位为微克每千克(ug/kg);xi

标准溶液中氯霉素的含量,单位为微克每千克(μg/kg);a——工作曲线的截距;

b—工作曲线的斜率;

样品溶液中氯霉素峰面积/氯霉素-d5峰面积:标准溶液中氯霉素峰面积/氯霉素-d5峰面积;yi

工作曲线包括不同浓度的数目。8测定低限(LOQ)和回收率

测定低限(LOQ)

测定低限为0.3μg/kg。

8.2回收率

回收率的实验数据(在不同添加浓度范围内)如下:添加浓度在0.3ug/kg时,回收率范围为83.1%~106.7%;添加浓度在0.6μg/kg时,回收率范围为82.3%~106.8%;—添加浓度在0.8μg/kg时,回收率范围为82.6%~107.2%。10

......3)wwW.bzxz.Net

SN/T2063—2008

附录A

(资料性附录)

API4000LC-MS/MS系统电喷雾离子源参考条件1)监测离子对及电压参数:

电喷雾电压(IS):-4500V;

雾化气压力(GS1):262.01kPa(38Psi);气帘气压力(CUR):186.165kPa(27Psi);辅助气流速(GS2):310.275kPa45Psi);离子源温度(TEM):525℃;

碰撞气(CAD):41.37kPa(6Psi);离子对、去簇电压(DP)、碰撞气能量(CE)及碰撞室出口电压(CXP)见表A.1。表A.1

待测物

氯霉素

氯霉素-d5

a为定量离子对。

离子对、去簇电压(DP)、碰撞气能量(CE)及碰撞室出口电压(CXP)离子对

321.0/256.9a

321.0/152,0

321.0/194.0

321.0/175.8

326.0/157.1

去簇电压(DP)/

碰撞气能量(CE)/

碰撞室出口电压

(CXP)/V

1)非商业性声明:附录A所列参数是在API4000质谱仪完成的,此处列出试验用仪器型号仅是为了提供参考,并不涉及商业目的,鼓励标准使用者尝试不同厂家和型号的仪器4

附录B

(资料性附录)

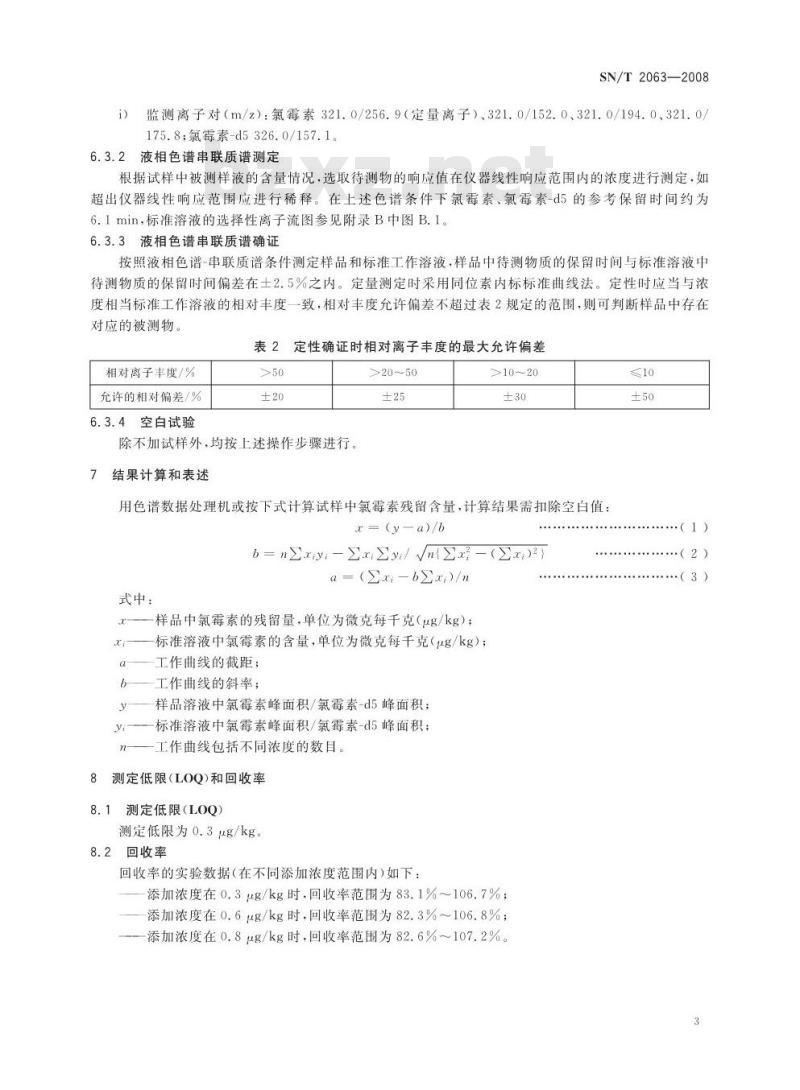

氯霉素标准品选择性离子流图

321.0/152.0

3.61 3.66 4.18 4.

3.0 3. 532

21. 0/2h6. 4

SN/T2063-2008

321.0/191.0

2.8.5ob.195.60

321. 0/17a. 8

3. 85. 4. 19 4. 48 1. 83

326. 0/157. 1

216 55 6. 99 7. 27 7. 56 7. 66t.5

7. 25 7. 1117. 58

氯霉素(0.24ng/mL)和氯霉素-d5(0.25ng/mL)标准品的选择性离子流图7. 5

SN/T2063—2008

Foreword

AnnexAandannexBofthis standardare informativeannex.This standard was proposed by and is under the charged of certification and accreditation administa-tionofthePeople'sRepublicofChina.This standard was drafted by Zhejiang Entry-Exit Inspection and Quarantine Bureau of the People'sRepublic of China.

The standard was mainly drafted by WenXie,Hui-yin Ding,Yan Qian,Jun-yang Xi,Xiao-mei ChenLei-fang Huang

This standard is a professional standard for entry-exit inspection and quarantinepromulgated for thefirsttime.

Note:This EnglishVersion,a translation from the Chinese text,is solely for guidance,6

SN/T 2063—2008

Determination of chloramphenicol residue in royaljellyfor importandexportLC-MS/MSScope

The standard specifiesthemethodsof samplepreparation and determinationbyLC-Ms/MS of chlor-amphenicolinroyal jelly.

This standard is applicableto thedetermination of chloramphenicol residue in royal jelly sample.2

Principle

Methanol is used to precipitate protein. The upper layer is extracted with ethyl acetate Then it isevaporated and cleaned up with silica and Oasis HLB columns. Finally it is determined and confirmedby LC-MS/MS.Internal standard method is used3

Reagentsandmaterials

Unless otherwise specified,all reagents used should be analytical grade,\water\is double distilledwater.

Ethylacetate:HPLCgrade.

Methanol:HPLCgrade

Toluene:HPLC grade.

Sodium chloride

Anhydroussodiumsulphate:Ignitefor4hat65o℃,cooltoroomtemperature indesiccatorand keep in atightlyclosed container.3.6

Methanolwatersolution:methanol-water(2+8,V/V)Toluene-acetonitrile (9+1,V/V)Toluene-acetonitrile(4+6,V/V)SN/T2063—2008

Chloramphenicol(CASNO.56-75-7.C11H12Cl2N2O):Purity≥99%Chloramphenicol-d5:Purity≥99%3.10

Stock standard solution of chloramphenicol:Accuratelyweigh appropriatestandard(3.9).dissolve with methanol, the concentration of solution is 100 μg/mL. should be stored at 1℃ ~4℃ inrefrigerator.Stock standard solution is stable for 6months.3.12

Stock standard solution of chloramphenicol-d5:Accurately weigh appropriate standard(3.10),dissolve with methanol,the concentration of solution is 100 μg/mL.Should be stored at1℃~4 inrefrigerator.Stockstandardsolutionisstablefor6months.Calibration curve standard working solutions: Working solutions were prepared in methanol3.13

atfiveconcentrationlevels,0.04ng/mL,0.12ng/mL,0.24ng/mL,0.32ng/mL.0.64ng/mL,TheconcentrationofCAP-d5is0.25ng/mL.Itissameas0.1μg/kg,0.3μg/kg,0.6μg/kg.0.8μg/kg1.6μg/kgchloramphenicolinsample3.14Column of anhydrous sodium sulfate:80 mmx 40 mm(i.d.)cylinder funnel,pack with ca5 mm absorbent cotton at the bottom of the column and fill in 40 mm anhydrous sodium sulfate3.15

Silica column:500 mg,or equivalent.Itis conditioned with 10 mLtoluene-acetonitrile(9+1,V/V).

3.16Oasis HLB column:500mg,or equivalent.It is conditioned with7mL methanol followedby10mLwater.

Apparatusandequipment

Liquidchromatographycombinedwithelectrosprayionizationmassspectrometry.Rotaryvacuum evaporator.

Vortex mixer.

SPE-12GColumn Processor.

Highspeedcentrifuge:7ooor/minNitrogenevaporator.

Preparation of testsample

SN/T2063—2008

Royal jelly is about 500 g.The sample is melted under room temperature. Keep the prepared sampleinto two sample bottles, seal and label.The test sample is stored at room temperature.The restsampleisstored in-18refrigerator.In the course of sample preparation, precautions must be taken to avoid contamination or any fac-tors,whichmaycausethechangeof residuecontent.AnalyticalProcedure

Extraction

Weigh ca 4gof the test sample(accurate to0.01g)intoa50mL centrifuge tube,add0.5mLCAP-d5(5ng/mL)and15mLwater,andmixthe solution,standingfor5min.Adjustvolumeto30.0mLwith methanol.Vortexfor1min under2000 r/min,centrifuge for5minunder6000 r/min.Transfer15.0 mL the supernatant layer into a 50 mL centrifuge tube, add 2 g sodium chloride and 20 mL ethylacetate.Vortex for1min under2000 r/min,centrifuge for 5min under 4 000 r/min.The superna-tant layer was passed through anhydrous sodiumsulfate column into flask(3.14).Repeat the extrac-tion in the same way with 20 mL ethyl acetate and combined the solution. Ethyl acetate is evaporat-edtonearlydrynessinawaterbathbelow4o℃.6.2

Cleanup

Add 10 mL toluene-acetonitrile (9 +1,V/V) to dissolve residues.Transfer the solution into silicacolumn(3.15).Discardtheeluate.Elutethecolumnwith6mLtoluene-acetonitrile(4+6,V/V).The above solution is under a gentle stream of nitrogen gas to nearly dryness. Add 5 mL water todissolve residues.Transfer the solution into Oasis HLB column (3.16),Rinse the tube and Oasis HLBcolumnwith10mLwaterandfollowedby5mLmethanol water solution(3.6),discard theeluate.Thecartridgeisevacuatedcontinuouslyto“dryness\.Elutethecolumnwith5mLmethanol,flowrateis 1 mL/min~2mL/min,and collect eluted solution.Theabovesolution is under a gentlestream of nitrogen gas to 2.5 mL at 50℃. Adjust volume of eluate to 5.0 mL with water. The solu-tion is passed throughO.45 μm filter.The solution was used for LC-MS/MS determination.Determination

LC-MS/MS operating conditionsColumn:Cg,5μm,150mmx4.6mmi.d),ortheequivalent;Mobilephase:table1;

SN/T2063—2008

Time/min

Flowrate:400μL/min;

InjectionVolume:20μL;

Source:ESl;

Polarity:Negative;

Table 1-Gradient of mobile phaseWater/%

Mode:Multiplereactionmonitoring;Methanol/%

Carrier gas:Nitrogen(purity>99.999%).Instrumental settingsmaybe optimized.$Seetable

A.1 in annex A;

Transitions(m/z):CAP321.0/256.9(quantification),321.0/152.0,321.0/194.0,321.0/175.8;CAP-d5326.0/157.1(quantification).6.3.2

LC-MS/MSdetermination

Accordingtotheconcentrations of analyte in sample solutioncontains should bewithin the linearrange of the calibration curve. If it is over the range,the solution should be diluted. Under the aboveLC-MS/MS operating condition,the retention time of CAP and CAP-d5 are about 6.1min,selectedion chromatograms of the standards see Figure B. 1 in annex B. Internal standard method is used.6.3.3

LC-MS/MSconfirmation

Under LC-MS/MS conditions,the working solution and sample solution are injected.The retentiontime of the analyte in sample solution shall correspond to that of the analyte in standard solution.Toleranceiswithin±2.5%.Calibration curvemethod withisotopeinternal standard isusedforquantitativemeasurement.The relative intensities of sampletransitions shall correspondtothoseofstandard solution transitions forconfirmation.The concentration of standard solution should besame with those of sample solution. The permitted tolerances listed in table 2, then the correspond-inganalytemustbepresentinsample.Table2-Maximum permittedtolerances for relativeion intensitieswhile confirmationRelative intensity/%

Permitted tolerances/%

>20~50

>10~20

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

进出口蜂王浆中氯霉素

残留量的检测方法

液相色谱串联质谱法

Determination of chloramphenicol residue in royajellyfor import and export-LC-MS/MS2008-04-29发布

中华人民共和国

国家质量监督检验检疫总局

2008-11-01实施

本标准的附录A和附录B均为资料性附录。本标准由国家认证认可监督管理委员会提出并归口。本标准起草单位:中华人民共和国浙江出入境检验检疫局。本标准主要起草人:谢文、丁慧瑛、钱艳、昊君阳、陈笑梅、黄雷芳本标准系首次发布的出入境检验检疫行业标准SN/T2063—2008

1范围

进出口蜂王浆中氯霉素

残留量的检测方法

液相色谱串联质谱法

本标准规定了蜂主浆中氯霉素残留量的制样和液相色谱串联质谱测定方法本标准适用于蜂主浆中氯霉素残留量的检测2方法提要

SN/T2063—2008

样品用甲醇沉淀蛋白质,再用乙酸乙酯提取,经硅胶和OasisHLB固相萃取小柱净化,液相色谱串联质谱测定和确证,同位素内标法定量3试剂和材料

除另有规定外,所有试剂均为分析纯,水为二次蒸馏水。3.1乙酸乙酯:高效液相色谱级。3.2甲醇:高效液相色谱级。

3.3甲苯:高效液相色谱级。

3.4氯化钠。

3.5无水硫酸钠:650℃灼烧4h,在干燥器内冷却至室温,贮于密封瓶中备用3.6甲醇水溶液:甲醇-水(2+8.体积比)。3.7甲苯-乙睛(9十1.体积比)。3.8甲苯-乙睛(4十6.体积比)。3.9氯霉素标准品(chloramphenicol.CASNO.56-75-7.CuH12ClzN2O,):纯度大于等于99%。3.10氯霉素-d5标准品:纯度大于等于99%。3.11氯霉素标准储备溶液:称取适量标准品(3.9),用甲醇溶解,溶液浓度为100ug/mL。1℃~4℃冷藏保存。有效期6个月。

3.12氯霉素-d5标准储备溶液:称取适量标准品(3.10).用甲醇溶解,溶液浓度为100μg/mL,1℃~4℃冷藏保存。有效期6个月。

3.13标准工作溶液:根据需要用空白样品溶液将标准储备液稀释成0.04ng/ml、0.12ng/mL、0.24ng/mL、0.32ng/mL、0.64ng/mL的标准工作溶液,相当于样品中含有0.1μg/kg、0.3μg/kg、0.6ug/kg、0.8μg/kg、1.6μg/kg氯霉素,同位素内标氯霉素-d5浓度均为0.25ng/mL。3.14无水硫酸钠柱:80mm×40mm(内径)筒形漏斗,底部垫5mm脱脂棉,再装40mm无水硫酸钠。3.15硅胶固相萃取柱:500mg或相当者,使用前用10mL甲苯-乙(9+1.体积比)预洗。3.16OasisHLB固相萃取柱:500mg,或相当者.使用前用甲醇7mL和水10mL预洗。4仪器和设备

4.1高效液相色谱-串联质谱仪:配有电喷雾离子源。4.2旋转蒸发器

4.3旋涡混合器。

SN/T2063—2008

固相萃取装置。

4.5高速离心机:7000r/min。

4.6氮吹仪。

5试样制备与保存

取500g代表性蜂王浆样品,在室温下解冻,等样品全部融化后搅匀,将试样均分成两份,分别装入样品瓶中,密封,并标明标记。“一份作为试验样,另一份在一18℃保存。在制样的操作过程中,应防止样品污染或发生残留物含量的变化。6测定步骤

6.1提取

称取4g试样(精确到0.01g)置于50mL具塞离心管中,准确加人0.5mL氯霉素-d5(5ng/mL)内标溶液和15mL水,混匀,静置5min,加甲醇至30.0mL,于旋涡混合器上以2000r/min,混匀1min,以6000r/min离心5min,移取15.0mL上层液置于另一个50mL具塞离心管中,加人2g氯化钠和20mL乙酸乙酯,于旋涡混合器上以2000r/min,混勺1min,以4000r/min离心5min,将上层乙酸乙酯过无水硫酸钠柱(3.14)收集于浓缩瓶中,再加入20mL乙酸乙酯,重复上述操作,合并乙酸乙酯提取液.再用5mL乙酸乙酯洗涤无水硫酸钠柱,在40℃以下水浴减压浓缩至近干。6.2净化

用10mL乙睛-甲苯(1十9.体积比)溶液溶解残渣,将溶解液分次转移至硅胶净化柱(3.15)中,弃去流出液,用6mL乙腈-甲苯(6十4,体积比)洗脱,在50℃以下水浴下平缓氮气吹干,加入5mL水溶解残渣,将溶液转移至OasisHLB柱(3.16)中,再用10mL水和5mL甲醇水溶液(3.6)依次洗涤离心管,洗涤液过固相萃取小柱,弃去流出液。在负压下减压抽干,最后用5mL甲醇洗脱,控制流速1mL/min~2mL/min,收集全部洗脱液于10mL离心管中,洗脱液在50℃以下水浴下平缓氮气吹至约2.5mL,用水定容至5.0mL混匀,将溶液通过0.45μm滤膜,供液相色谱-串联质谱仪测定6.3测定

液相色谱串联质谱条件

色谱柱:C柱,5μm,150mm×4.6mm(内径)或相当者;a)

流动相见表1;

流动相梯度洗脱

时间/min

流速:400μL/min;

进样量:20μL;

离子源:电喷雾离子源;

扫描方式:负离子扫描;

检测方式:多反应监测;

甲醇/%

雾化气、气帘气、辅助气、碰撞气均为高纯氮气:使用前应调节各参数使质谱灵敏度达到检测要求,参考条件参见附录A;

SN/T2063—2008

监测离子对(m/z):氯霉素321.0/256.9(定量离子)、321.0/152.0、321.0/194.0、321.0/175.8:氯霉素-d5326.0/157.1。6.3.2液相色谱串联质谱测定

根据试样中被测样液的含量情况,选取待测物的响应值在仪器线性响应范围内的浓度进行测定,如超出仪器线性响应范围应进行稀释。在上述色谱条件下氯每素、氯素-d5的参考保留时间约为6.1min,标准溶液的选择性离子流图参见附录B中图B.1。6.3.3液相色谱串联质谱确证

按照液相色谱-串联质谱条件测定样品和标准工作溶液,样品中待测物质的保留时间与标准溶液中待测物质的保留时间偏差在士2.5%之内。定量测定时采用同位素内标标准曲线法。定性时应当与浓度相当标准工作溶液的相对丰度一致,相对丰度允许偏差不超过表2规定的范围,则可判断样品中存在对应的被测物。

表2定性确证时相对离子丰度的最大允许偏差相对离子丰度/%

允许的相对偏差/%

6.3.4空白试验

除不加试样外,均按上述操作步骤进行。7结果计算和表述

>20~50

>10~20

用色谱数据处理机或按下式计算试样中氯霉素残留含量,计算结果需扣除空白值:a=(y-a)/b

b=nZriyr-Eyi/n(a-())

a=(i-ba)/m

式中:

样品中氯霉素的残留量,单位为微克每千克(ug/kg);xi

标准溶液中氯霉素的含量,单位为微克每千克(μg/kg);a——工作曲线的截距;

b—工作曲线的斜率;

样品溶液中氯霉素峰面积/氯霉素-d5峰面积:标准溶液中氯霉素峰面积/氯霉素-d5峰面积;yi

工作曲线包括不同浓度的数目。8测定低限(LOQ)和回收率

测定低限(LOQ)

测定低限为0.3μg/kg。

8.2回收率

回收率的实验数据(在不同添加浓度范围内)如下:添加浓度在0.3ug/kg时,回收率范围为83.1%~106.7%;添加浓度在0.6μg/kg时,回收率范围为82.3%~106.8%;—添加浓度在0.8μg/kg时,回收率范围为82.6%~107.2%。10

......3)wwW.bzxz.Net

SN/T2063—2008

附录A

(资料性附录)

API4000LC-MS/MS系统电喷雾离子源参考条件1)监测离子对及电压参数:

电喷雾电压(IS):-4500V;

雾化气压力(GS1):262.01kPa(38Psi);气帘气压力(CUR):186.165kPa(27Psi);辅助气流速(GS2):310.275kPa45Psi);离子源温度(TEM):525℃;

碰撞气(CAD):41.37kPa(6Psi);离子对、去簇电压(DP)、碰撞气能量(CE)及碰撞室出口电压(CXP)见表A.1。表A.1

待测物

氯霉素

氯霉素-d5

a为定量离子对。

离子对、去簇电压(DP)、碰撞气能量(CE)及碰撞室出口电压(CXP)离子对

321.0/256.9a

321.0/152,0

321.0/194.0

321.0/175.8

326.0/157.1

去簇电压(DP)/

碰撞气能量(CE)/

碰撞室出口电压

(CXP)/V

1)非商业性声明:附录A所列参数是在API4000质谱仪完成的,此处列出试验用仪器型号仅是为了提供参考,并不涉及商业目的,鼓励标准使用者尝试不同厂家和型号的仪器4

附录B

(资料性附录)

氯霉素标准品选择性离子流图

321.0/152.0

3.61 3.66 4.18 4.

3.0 3. 532

21. 0/2h6. 4

SN/T2063-2008

321.0/191.0

2.8.5ob.195.60

321. 0/17a. 8

3. 85. 4. 19 4. 48 1. 83

326. 0/157. 1

216 55 6. 99 7. 27 7. 56 7. 66t.5

7. 25 7. 1117. 58

氯霉素(0.24ng/mL)和氯霉素-d5(0.25ng/mL)标准品的选择性离子流图7. 5

SN/T2063—2008

Foreword

AnnexAandannexBofthis standardare informativeannex.This standard was proposed by and is under the charged of certification and accreditation administa-tionofthePeople'sRepublicofChina.This standard was drafted by Zhejiang Entry-Exit Inspection and Quarantine Bureau of the People'sRepublic of China.

The standard was mainly drafted by WenXie,Hui-yin Ding,Yan Qian,Jun-yang Xi,Xiao-mei ChenLei-fang Huang

This standard is a professional standard for entry-exit inspection and quarantinepromulgated for thefirsttime.

Note:This EnglishVersion,a translation from the Chinese text,is solely for guidance,6

SN/T 2063—2008

Determination of chloramphenicol residue in royaljellyfor importandexportLC-MS/MSScope

The standard specifiesthemethodsof samplepreparation and determinationbyLC-Ms/MS of chlor-amphenicolinroyal jelly.

This standard is applicableto thedetermination of chloramphenicol residue in royal jelly sample.2

Principle

Methanol is used to precipitate protein. The upper layer is extracted with ethyl acetate Then it isevaporated and cleaned up with silica and Oasis HLB columns. Finally it is determined and confirmedby LC-MS/MS.Internal standard method is used3

Reagentsandmaterials

Unless otherwise specified,all reagents used should be analytical grade,\water\is double distilledwater.

Ethylacetate:HPLCgrade.

Methanol:HPLCgrade

Toluene:HPLC grade.

Sodium chloride

Anhydroussodiumsulphate:Ignitefor4hat65o℃,cooltoroomtemperature indesiccatorand keep in atightlyclosed container.3.6

Methanolwatersolution:methanol-water(2+8,V/V)Toluene-acetonitrile (9+1,V/V)Toluene-acetonitrile(4+6,V/V)SN/T2063—2008

Chloramphenicol(CASNO.56-75-7.C11H12Cl2N2O):Purity≥99%Chloramphenicol-d5:Purity≥99%3.10

Stock standard solution of chloramphenicol:Accuratelyweigh appropriatestandard(3.9).dissolve with methanol, the concentration of solution is 100 μg/mL. should be stored at 1℃ ~4℃ inrefrigerator.Stock standard solution is stable for 6months.3.12

Stock standard solution of chloramphenicol-d5:Accurately weigh appropriate standard(3.10),dissolve with methanol,the concentration of solution is 100 μg/mL.Should be stored at1℃~4 inrefrigerator.Stockstandardsolutionisstablefor6months.Calibration curve standard working solutions: Working solutions were prepared in methanol3.13

atfiveconcentrationlevels,0.04ng/mL,0.12ng/mL,0.24ng/mL,0.32ng/mL.0.64ng/mL,TheconcentrationofCAP-d5is0.25ng/mL.Itissameas0.1μg/kg,0.3μg/kg,0.6μg/kg.0.8μg/kg1.6μg/kgchloramphenicolinsample3.14Column of anhydrous sodium sulfate:80 mmx 40 mm(i.d.)cylinder funnel,pack with ca5 mm absorbent cotton at the bottom of the column and fill in 40 mm anhydrous sodium sulfate3.15

Silica column:500 mg,or equivalent.Itis conditioned with 10 mLtoluene-acetonitrile(9+1,V/V).

3.16Oasis HLB column:500mg,or equivalent.It is conditioned with7mL methanol followedby10mLwater.

Apparatusandequipment

Liquidchromatographycombinedwithelectrosprayionizationmassspectrometry.Rotaryvacuum evaporator.

Vortex mixer.

SPE-12GColumn Processor.

Highspeedcentrifuge:7ooor/minNitrogenevaporator.

Preparation of testsample

SN/T2063—2008

Royal jelly is about 500 g.The sample is melted under room temperature. Keep the prepared sampleinto two sample bottles, seal and label.The test sample is stored at room temperature.The restsampleisstored in-18refrigerator.In the course of sample preparation, precautions must be taken to avoid contamination or any fac-tors,whichmaycausethechangeof residuecontent.AnalyticalProcedure

Extraction

Weigh ca 4gof the test sample(accurate to0.01g)intoa50mL centrifuge tube,add0.5mLCAP-d5(5ng/mL)and15mLwater,andmixthe solution,standingfor5min.Adjustvolumeto30.0mLwith methanol.Vortexfor1min under2000 r/min,centrifuge for5minunder6000 r/min.Transfer15.0 mL the supernatant layer into a 50 mL centrifuge tube, add 2 g sodium chloride and 20 mL ethylacetate.Vortex for1min under2000 r/min,centrifuge for 5min under 4 000 r/min.The superna-tant layer was passed through anhydrous sodiumsulfate column into flask(3.14).Repeat the extrac-tion in the same way with 20 mL ethyl acetate and combined the solution. Ethyl acetate is evaporat-edtonearlydrynessinawaterbathbelow4o℃.6.2

Cleanup

Add 10 mL toluene-acetonitrile (9 +1,V/V) to dissolve residues.Transfer the solution into silicacolumn(3.15).Discardtheeluate.Elutethecolumnwith6mLtoluene-acetonitrile(4+6,V/V).The above solution is under a gentle stream of nitrogen gas to nearly dryness. Add 5 mL water todissolve residues.Transfer the solution into Oasis HLB column (3.16),Rinse the tube and Oasis HLBcolumnwith10mLwaterandfollowedby5mLmethanol water solution(3.6),discard theeluate.Thecartridgeisevacuatedcontinuouslyto“dryness\.Elutethecolumnwith5mLmethanol,flowrateis 1 mL/min~2mL/min,and collect eluted solution.Theabovesolution is under a gentlestream of nitrogen gas to 2.5 mL at 50℃. Adjust volume of eluate to 5.0 mL with water. The solu-tion is passed throughO.45 μm filter.The solution was used for LC-MS/MS determination.Determination

LC-MS/MS operating conditionsColumn:Cg,5μm,150mmx4.6mmi.d),ortheequivalent;Mobilephase:table1;

SN/T2063—2008

Time/min

Flowrate:400μL/min;

InjectionVolume:20μL;

Source:ESl;

Polarity:Negative;

Table 1-Gradient of mobile phaseWater/%

Mode:Multiplereactionmonitoring;Methanol/%

Carrier gas:Nitrogen(purity>99.999%).Instrumental settingsmaybe optimized.$Seetable

A.1 in annex A;

Transitions(m/z):CAP321.0/256.9(quantification),321.0/152.0,321.0/194.0,321.0/175.8;CAP-d5326.0/157.1(quantification).6.3.2

LC-MS/MSdetermination

Accordingtotheconcentrations of analyte in sample solutioncontains should bewithin the linearrange of the calibration curve. If it is over the range,the solution should be diluted. Under the aboveLC-MS/MS operating condition,the retention time of CAP and CAP-d5 are about 6.1min,selectedion chromatograms of the standards see Figure B. 1 in annex B. Internal standard method is used.6.3.3

LC-MS/MSconfirmation

Under LC-MS/MS conditions,the working solution and sample solution are injected.The retentiontime of the analyte in sample solution shall correspond to that of the analyte in standard solution.Toleranceiswithin±2.5%.Calibration curvemethod withisotopeinternal standard isusedforquantitativemeasurement.The relative intensities of sampletransitions shall correspondtothoseofstandard solution transitions forconfirmation.The concentration of standard solution should besame with those of sample solution. The permitted tolerances listed in table 2, then the correspond-inganalytemustbepresentinsample.Table2-Maximum permittedtolerances for relativeion intensitieswhile confirmationRelative intensity/%

Permitted tolerances/%

>20~50

>10~20

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

标准图片预览:

- 热门标准

- 商检行业标准(SN)

- SN/T1688.6-2012 进出口机动车辆检验规程第6部分:发动机

- SN/T2404-2009 玩具中防腐剂2-甲基-4-异噻唑啉-3-酮及其衍生物的测定

- SN/T2004.2-2005 电子电气产品中铅、镉、铬的测定 第2部分:火焰原子吸收光谱法

- SN/T2648-2010 进出口食品中啶酰菌胺残留量的测定 气相色谱-质谱法

- SN/T2927-2011 出口水处理用无烟煤滤料检验规程

- SN/T3591-2013 实验室标准物质管理指南

- SN/T3764-2013 猕猴桃举肢蛾检疫鉴定方法

- SN/T1077-2002 进出口无梭织造棉本色布/精梳 涤棉混纺本色布检验规程

- SN/T1349-2004 山松大小蠹检疫鉴定方法

- SN/T1667.2-2007 进出口机电产品检测方法 第2部分:彩色液晶显示器件电光性能的测量

- SN/T1743-2006 食品中诱惑红、酸件红、亮蓝、日落黄的含量检测高效液相色谱法

- SN/T2329-2009 化妆品眼刺激性/腐蚀性的鸡胚绒毛尿囊试验

- SN/T2870-2011 中肠腺坏死杆状病毒病检疫技术规范

- SN/T1589.7-2013 进出口家用和类似用途电器检验规程 第7部分:空气净化器

- SN/T1603.1-2012 进出口音视频及类似电子设备检验规程 第1部分:通用要求

- 行业新闻

请牢记:“bzxz.net”即是“标准下载”四个汉字汉语拼音首字母与国际顶级域名“.net”的组合。 ©2025 标准下载网 www.bzxz.net 本站邮件:bzxznet@163.com

网站备案号:湘ICP备2025141790号-2

网站备案号:湘ICP备2025141790号-2