- 您的位置:

- 标准下载网 >>

- 标准分类 >>

- 商检行业标准(SN) >>

- SN 0637-1997 出口油籽坚果及坚果制品中黄曲霉毒素的检验方法液相色谱法

标准号:

SN 0637-1997

标准名称:

出口油籽坚果及坚果制品中黄曲霉毒素的检验方法液相色谱法

标准类别:

商检行业标准(SN)

标准状态:

现行-

发布日期:

1997-08-15 -

实施日期:

1998-01-01 出版语种:

简体中文下载格式:

.rar.pdf下载大小:

315.29 KB

点击下载

标准简介:

标准下载解压密码:www.bzxz.net

本标 准 规 定了出口油籽、坚果及坚果制品中黄曲霉毒素检验的抽样、制徉和液相色谱测定方法。本 标 准 适用于出口花生仁和杏仁中黄曲霉毒素B B,,G G:的检验。 SN 0637-1997 出口油籽坚果及坚果制品中黄曲霉毒素的检验方法液相色谱法 SN0637-1997

部分标准内容:

中华人民共和国进出口商品检验行业标准SN0637-1997

出口油籽、坚果及坚果制品中

黄曲霉毒素的检验方法液相色谱法Method for the determination of aflatoxins in oilseeds,nuts and nutproducts for export---Liquid chromatographic method1997-08-15发布

1998-01-01实施

中华人民共和国国家进出口商品检验局发布SN06371997

本标准是根据GB/T1.1一1993《标准化工作导则第1单元:标准的起草与表述规则第1部分:标准编写的基本规定》及SN/T0001一1995《出口商品中农药、兽药残留量及生物毒素检验方法标准编写的基本规定》的要求进行编写的。其中测定方法是参考国内外有关文献,经研究、改进和验证后制定的。本标准同时制定了抽样和制样方法。测定低限是根据国际上对油籽、坚果及坚果制品中黄曲霉毒素BI、Bz、GI、G2最高限量和测定方法的灵敏度而制定的。

本标准的附录A为提示的附录。

本标准由中华人民共和国国家进出口商品检验局提出并归口。本标准由中华人民共和国河北进出口商品检验局负责起草。本标准主要起草人:任世国、段文仲、郝冬生、白玉良。本标准系首次发布的行业标准。1范围

中华人民共和国进出口商品检验行业标准出口油籽、坚果及坚果制品中

黄曲霉毒素的检验方法液相色谱法Method for the determination of aflatoxins in oilseeds, nuts and nut products for export-Liquid chromatographic methodSN0637-1997

本标准规定了出口油籽、坚果及坚果制品中黄曲霉毒素检验的抽样、制样和液相色谱测定方法。本标准适用于出口花生仁和杏仁中黄曲霉毒素B、B2、GI、G,的检验。2抽样和制样

2.1检验批

花生仁以不超过200t(2400袋)为一检验批;杏仁以不超过50t(625袋)为一检验批。同一检验批的商品应具有相同的特征,如包装、标记、产地、规格和等级等。2.2抽样数量

按式(1)计算抽样袋数:

全批袋数:

式中:N—全

a-抽样袋数。

注:a值取整数,小数部分向前进位为整数。2.3抽样工具

2.3.1取样铲或取样勺。

2.3.2盛样袋:可密封。

2.3.3分样板。

2.3.4分样布。

2.4抽样方法

2.4.1倒包抽样:从堆垛的各部位随机抽取2.2规定的应抽样袋数的10%(每批一般不少于3袋),将袋口缝线全部拆开,平置于分样布上,双手紧握袋底两角,提起约成45°倾角,倒拖约1m,使袋内货物全部倒出。查看袋内和袋间品质是否一致。确认情况正常后,用取样铲随机在各部位抽取样品,立即倒入盛样袋中。每袋抽取的样品数量应基本一致。2.4.2袋内取样:按2.2规定的应抽样袋数的90%,在堆垛四周上、中、下各层以曲线形走向随机抽取样袋。将所抽各袋拆开袋口缝线3~5针,用取样勺从开口处抽取样品。立即缝好袋口,并将所取样品倒入盛样袋中,每袋抽取样品数量应与2.4.1基本一致。每批所抽取的样品总量应不少于4kg。2.4.3大样缩分:合并倒包和袋内取样所取全部样品,倒于分样布上,用分样板按四分法分出样品不少中华人民共和国国家进出口商品检验局1997-08-15批准1998-01-01实施

SN 06371997

于2kg,倒入样品袋中,加封后标明标记,并及时送交实验室。2.5试样制备

2.5.1制样工具

2.5.1.1切碎机或粉碎机。

2.5.1.2筛子:2.0mm圆孔筛。

2.5.1.3分样板。

2.5.1.4盛样瓶:具塞广口瓶。

2.5.2制样方法

将所取样品,用四分法缩分出约200g。用切碎机或粉碎机将缩分出的样品全部切碎或粉碎成尺寸不大于1mm并通过2.0mm圆孔筛碎粒。充分混匀,均分成两份作为试样,分装于洁净的盛样瓶中,密封,标明标记。

2.6试样保存

将试样于一5℃以下避光保存。

注:在抽样及制样的操作过程中,必须防止样品受到污染或发生残留物含盘的变化。3测定方法

3.1方法提要

试样中的黄曲霉毒索B、B2、G、G用三氯甲烷提取,提取液经弗罗里硅土柱净化,浓缩,定容。溶液用柱后衍生-液相色谱荧光检测器法测定,外标法定量。3.2试剂和材料

除另有规定外,所用试剂均为分析纯,水为蒸馏水。3.2.1三氯甲烷。

3.2.2丙酮。

3.2.3苯。

3.2.4乙腈。

3.2.5甲醇:紫外光谱纯。

5无水硫酸钠:600℃灼烧4h.贮于干燥器中备用。3.2.6

硅藻土:Celit545。

弗罗里硅土:60~100目,600℃灼烧4h,使用前于130℃活化3h,贮于干燥器中备用。3.2.8

3.2.9过溴化溴化吡啶(pyridiniumbromideperbromide)。3.2.10黄曲霉毒素BI、B2、GI、Gz标准品:纯度均≥99%。标准储备液:分别称取适量的黄曲霉毒素B,、BaG,G标准品,分别用少量苯溶解并用乙腈配3.2.11

成浓度为0.100mg/mL的标准储备液。3.2.12混合标准工作液:根据需要准确移取适量的黄曲霉毒素B,、B2、G,和G,的标准储备液,用乙睛稀释成适当浓度的混合标准工作液。3.3仪器和设备

3.3.1液相色谱仪并配有荧光检测器和柱后衍生化装置。3.3.2微量混和器。

3.3.3抽滤瓶。

3.3.4真空泵。

3.3.5旋转蒸发器。

3.3.6净化柱:玻璃柱,30cm×20mm(内径),用三氯甲烷湿法依次装入1.0g无水硫酸钠,0.7g弗罗里硅土,5.0g无水硫酸钠。

3.4测定步骤

3.4.1提取

SN0637-1997

称取约20g试样(精确至0.1g)于250mL具塞锥形瓶中,加入10mL水使试样充分湿润。加入5.0g硅藻土,并准确加入100mL三氯甲烷,于微量混和器上快速振荡5min。提取液经抽滤后过无水硫酸钠柱,收集50mL。

3.4.2净化

准确移取50.0mL上述提取液,注入弗罗里硅土净化柱中,用2×10mL三氯甲烷洗涤容器及玻璃柱,调节流速为2mL/min。待溶液全部流出后,用20mL三氯甲烷-甲醇(9十1)淋洗柱子,弃去全部流出液。用50mL丙酮-水(99+1)洗脱,收集洗脱液于心形瓶中。用旋转蒸发器于40℃水浴中减压蒸发至近干,再用氮气流吹干。准确加入2.0mL甲醇以溶解残渣,溶液供柱后衍生-液相色谱法测定。3.4.3测定

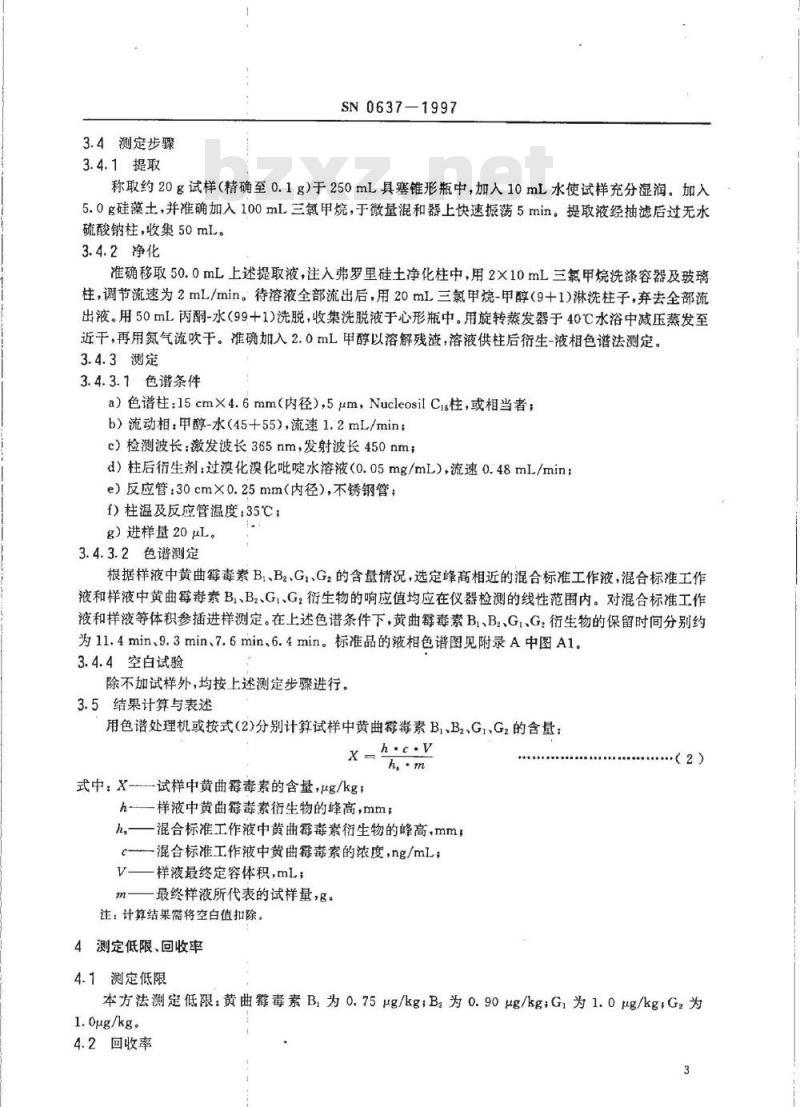

3.4.3.1色谱条件

a)色谱柱:15cm×4.6mm(内径),5μm,NucleosilCra柱,或相当者;b)流动相:甲醇-水(45+55),流速1.2mL/min;c)检测波长:激发波长365nm,发射波长450nm,d)柱后衍生剂:过溴化溴化吡啶水溶液(0.05mg/mL),流速0.48mL/min;e)反应管:30cm×0.25mm(内径),不锈钢管;f)柱温及反应管温度:35℃;

g)进样量20μL。

3.4.3.2色谱测定

根据样液中黄曲霉毒素B、Bz、G、G,的含量情况,选定峰高相近的混合标准工作液,混合标准工作液和样液中黄曲霉毒素BI、Bz、Gt、G?衍生物的响应值均应在仪器检测的线性范围内。对混合标准工作液和样液等体积参插进样测定。在上述色谱条件下,黄曲毒素BI、B2、Gl、G.衍生物的保留时间分别约为11.4min、9.3min、7.6min、6.4min。标准品的液相色谱图见附录A中图A1。3.4.4空白试验

除不加试样外,均按上述测定步骤进行。3.5结果计算与表述

用色谱处理机或按式(2)分别计算试样中黄曲毒素B、B,、G、Gz的含量:h.c.v

式中,X-—试样中黄曲霉毒素的含量,μg/kg;h--样液中黄曲霉毒素衍生物的峰高,mmh,一混合标准工作液中黄曲毒素衍生物的峰高,mm;一混合标准工作液中黄曲毒素的浓度,ng/mL;V—样液最终定容体积,mL

最终样液所代表的试样量,g。

注:计算结果需将空白值扣除。4测定低限、回收率

4.1测定低限

本方法测定低限:黄曲露毒素B,为0.75μg/kg;B,为0.90ug/kg;G为1.0μg/kgG,为1.Oμg/kg。

4.2回收率

SN0637-1997

杏仁和花生仁中黄曲霉毒素添加浓度及其回收率实验数据如下。4.2.1查仁中的回收率

黄曲霉毒素

4.2.2花生中的回收率

黄曲霉毒素

添加浓度(μg/kg)

添加浓度(μg/kg)

回收率

回收率

SN 06371997

附录A

(提示的附录)

标准品色谱图

注:色诺峰号1.2.3,4分别为黄曲群毒素Gz.G、B,、B,衍生物,保留时间分别为6.4min、7.6min、9.3min、11.4min。

黄曲爵毒素B、B2、GI、G.标准品衍生物的液相色谱图图A1

SN0637-1997

Foreword

This standard was drafted in accordance with the requirements of GB/T 1.1-1993\Directives forthe work of standardization-Unit l: Drafting and presentation of standards-Part l: General rulesfor drafting standards\ and presentation of standards and SN/T 0001-1995“General rules for draft-ing the standard methods for the determination of pesticide, veterinary drug residues and biotoxins incommodities for export\. The method of determination was drafted by referring to domestic and for-eign literatures through research, modification and verification, In addition, methods of sampling andsamplepreparation arealso specified in this standard.The limit of determination in this standard is defined on the basis of the curent internationalmaximum limit for aflatoxins B,,Bz,G,Gz in oil seeds, nuts and nut products and the sensitivity ofthe method.

Annex A of this standard is an informative annex.This standard was proposed by and is under the charge of the State Administration of Import andExport Commodity Inspection of the People's Republic of China.This standard was drafted by Hebei Import and Export Commodity Inspection bureau of the Peo-ple's Republic of China.

The main drafters of this standard are Ren Shiguo, Duan Wenzhong, Hao Dongsheng, Bai Yu-liang

This standard is a professional standard promulgated for the first time.Note:This English version,a translation fromn the Chinese text, is solely for guidance.6

Professional Standard of thePeople's Republic of Chinafor Import and Export Commodity InspectionMethod for the determination of aflatoxins in oilseeds,nuts and nutproducts forexport-Liquid chromatographic method1Scope

SN0637-1997

This standard specifies the method of sampling, sample preparation and determination by highperformance liquid chromatography of aflatoxins in oil seeds, nuts and nut products for export.This standard is applicable to the determination of aflatoxin Br, Bz, Gr,G,in peanut and almondforexport.

2 Sampling and samplepreparation2.1Inspectionlot

Each inspection lot, for peanut should not exceed 200 t (2 40o bags); for almond should not ex-ceed 50 t (625 bags).

The characteristics of the cargo within the same inspection lot, such as packing, mark, origin,specification and grade, should be the same.2.2Quantity of sampletaken

Calculate the number'of bags to be taken by formula (1):aN

N-total number of bags in a lot,a-number of bags to be taken.Note:If value a is with decimal,round off the decimal part,which is added as2.3 Sampling tools

2.3.1 Sampling shovel or ladle.2.3.2 Sampling bag, which can be sealed.2.3.3 Plate for quartering.

2.3.4 Cloth sheet:For sample quartering.2.4Samplingprocedure

(1)

y to the integral part of a.2.4.1 Sampling by emptying out: Draw 10o percent of the number of bags specified in 2.2 (not lessthan 3 bags) from differenit parts of the pile at random, Unseam and open the bag, and lay it on aclean cloth sheet. Grasp tight two corners of the bag bottom and raise up to an angle of 45'C, tugbackward for ca 1 m until all content of the bag is emptied out. Check whether the quality of theApproved by the State Administration ofImport and Export Commodity Inspection ofthePeople's Republic of China on Aug.15,1997Implemented from Jan.1,1998

SN0637-1997

goods are uniform within and between the bags. After confirming that the goods are in normal condi-tion, scoop up the sample from different parts of the out-poured content with a shovel,place in a sam-ple container promptly. The quantity of the sample drawn from each bag should be basically thesame.

2.4.2Sampling form inside the bag: Draw the samples from 90 percent of the number of bags speci-fied in 2. 2 as follows: Along the sine wave of the pile, draw the samples from the bags of the &pper,middle and lower parts around the pile at random. Partially unseam (3-5 stitches) the bags mouth,scoop out the sample with a sampling ladle at the bag opening. Promptly pour the sample into a sam-ple container and close the bag by seaming. The amount of the sample drawn from each bag should bebasically the same as in 2.4. 1.The total weight of the sample of each lot should be not less than 4 kg2. 4.3 Reduction of gross sample; Pour all the samples (from both 2. 4.1 and 2. 4. 2) onto a cleancloth sheet, reduce to not less than 2 kg with a plate by quartering. Place in a sample container, seal,label and send to the laboratory in time.2.5 Preparation of test sample2.5.1Sampling tools

2.5.1.1Sampleslicerorpulverizer.2.5.1.2 Seive:2.0 mm round-hole seive.2.5.1.3 Plate for quartering.2.5.1.4Samplecontainer:Widemouthbottle,withgroud stopper.2.5.2Procedure

Reduce the sample to ca 200 g by quartering.The sample is either sliced into thin pieces of lessthan I mm in size with a slicer or pulverized into granules with a pulverizer, let all pass through a2.o mm round-hole sieve. Mix thoroughly and divide into 2 equal portions, place in clean containersas the test samples, seal and label.2.6 Storage of test sample

The test sample shall be stored below -5C and kept away from light.Note: In the course of sampling and sample preparation, precautions must be taken to avoid the contamination orany factors which may cause the change of residue content.3Method of determination

3.1 Principle

The aflatoxins in the test sample are extracted with chloroform. The extract, after cleaning up bypass through a florisil column, is evaporated and made up to a definite volume. Determination is car-ried out by'post-column derivatization-high performance liquid chromatography with fluorescence detector, using external standard method.3.2 Reagents and materials

Unless otherwise specified, all the reagents should be analytically pure, \water\ is distilled wa-ter.

3.2.1 Chloroform.

3.2.2Acetone.

3.2.3 Benzene.

3.2.4Acetonitrile.

3.2.5Methanol:UVgrade.

SN 0637-1997

3.2.6 Anhydrous sodium sulfate: Ignite at 600C for 4 hours, keep in a desiccator.3.2.7Celite 545.www.bzxz.net

3.2.8Florisil,60—100mesh.Ignite at 600C for 4hours, and activate at 130C for3hours beforeuse,keep in a desiccator.

3.2.9 Pyridinium bromide perbromide.3.2.10AflatoxinB,Bz,Gr,Ggstandards:Purityall≥99%.3. 2. 11 Standard stock solution: Respectively weigh an adequate amount of each of aflatoxin Br, Br,Gr, Gz standard and dissolve each in a small amount of benzene. Dilute with acetonitrile to prepare thestandard stock solutions of o.1oomg/mL in concentration.3.2.12Mixed standard working solution: According to the requirment, pipet adequate amount ofaflatoxin Br, Bz, Gr, and Gz standard stock solutions, and dilute with acetonitrile to prepare a mixedstandard working solution of suitable concentrations.3.3Apparatus and equipments

3.3.1 Liquid chromatograph, equipped with fluorescence detector, and post-column derivatizer.3.3.2 Miniature mixer.

3.3.3 Suction bottle.

3.3.4Vacuumpump.

3.3.5Rotaryevaporator

3. 3. 6 Cleanup column; Glass column, 30 cmX20 mm (id), packed in sequence with 1.0 g of anhy-drous sodium sulfate, O.7 g of florisil and 5. g of anhydrous sodium sulfate by moistening with chlo-roform.

3.4 Procedure

3.4.1 Extraction

Weigh ca 20 g of the test sample (accurate to 0.1 g) into a 250 mL conical flask with stopper,add 10 mL of water to moisten the sample thoroughly.Add 5. 0 g of celite 545 and accurately add 100mL of chloroform, shake vigorously for 5 min on a miniature mixer. The extract, after filtered bysuction, is dehydrated by passing through an anhydrous sodium sulfate column, and 5o mL of the extract are collected.

3.4.2 Cleanup

Transfer exactly 50 mL of above extract into the packed cleanup column. Rinse the container andthe column with 2X10 ml of chloroform (adjusting theflow rate to 2 mL/min).When the solutiondrains out, wash the column with 20 mL of chloroform-methanol (9+1). Discard all of the above ef-fluents. Then elute with 50 mL of acetone-water (99+1), and collect the eluate into a heart-shapedflask. Evaporate to near dryness with a rotary evaporator under reduced pressure at 4o'C bath temper-ature and evaporate to dryness under a stream of nitrogen. Exactly add 2. O mL of methanol to dis-solve the residue, and the solution is used for liquid chromatographic determination.3.4.3Determination

3.4.3.1 HPLC operating conditiona)Column:15cmX4.6mm(id),5μm,Nucleosil Cig column,or equivalent;b)Mobilphase:methanol-water(45+55),1.2mL/min;c)Fluorescence detector:Excitation wavelength 365 nm, emission wavelength 450 nm;d) Reagent for post-column derivatization: Pyridinium bromide perbromide aqueous solution,9

SN 0637-1997

0.05mg/mL,flowrate:0.48mL/min,e)Reaction tube:30 cmXo.25mm (id),stainless steel tube;f) Column and reaction tube temperature: 35C;g)Injectionvolume:20 μL.

3.4.3.2HPLC determination

According to the concentrations of aflatoxin Br, Bz, G, and Gz in the sample solution, select themixed standard working solution with the similar peak heights to those of sample solution. The re-sponses of aflatoxin Br,Bz,G, and G,derivatives in the standard working solution and the sample so-lution should be within the linear range of the instrumental detection. The standard working solutionshould be randomly injected in-between the injections of sample solution of equal volume, Under theabove HPLC operating condition, the retention times of aflatoxin Br, Bz, G, and G, derivatives are11. 4, 9. 3, 7.6 and 6. 4 min respectively. For liquid chromatogram of the standards see fig.A1 inannex A.

3.4.4 Blank test

The operation of blank test is the same as that described in the method of determination, but withthe omission of sample addition.3. 5 Caleulation and expression of the resultsCalculate the results by LC data precessor or according to formula (2):X

X-thecontentofaflatoxinB,,Bz,G,orGzinthetest sample,μg/kg(2)

h-thepeak height of aflatoxin B,Bz,G,or Gzderivativein the sample solution,mm;h,the peak height of aflatoxin Br, Bz, G, or G2 derivative in the mixed standard working solu-tion,mm;

c--the concentration of aflatoxin B,Bz,G, or G, in the mixed standard working solution,ng/mL

V--the final volume of sample solution,mL,m-the corresponding mass of test sample in the final sample solution,g.Note: The blank value should be subtracted from the above result of calculation.4 Limit of determination and recovery4.1 Limit of determination

The limits of determination of this method are 0. 75 μg/kg, 0. 90 μg/kg, 1. 0 μg/kg and 1. Oμg/kgfor aflatoxinB,Ba,G,and G respectively4.2Recovery

According to the experimental data, the fortifying concentrations of various aflatoxins and theirrecoveries in almond and peanut are as follows.4.2.1 In almond

Aflatoxin

Fortifyingconcentration(μg/kg)0.75

Recovery

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

出口油籽、坚果及坚果制品中

黄曲霉毒素的检验方法液相色谱法Method for the determination of aflatoxins in oilseeds,nuts and nutproducts for export---Liquid chromatographic method1997-08-15发布

1998-01-01实施

中华人民共和国国家进出口商品检验局发布SN06371997

本标准是根据GB/T1.1一1993《标准化工作导则第1单元:标准的起草与表述规则第1部分:标准编写的基本规定》及SN/T0001一1995《出口商品中农药、兽药残留量及生物毒素检验方法标准编写的基本规定》的要求进行编写的。其中测定方法是参考国内外有关文献,经研究、改进和验证后制定的。本标准同时制定了抽样和制样方法。测定低限是根据国际上对油籽、坚果及坚果制品中黄曲霉毒素BI、Bz、GI、G2最高限量和测定方法的灵敏度而制定的。

本标准的附录A为提示的附录。

本标准由中华人民共和国国家进出口商品检验局提出并归口。本标准由中华人民共和国河北进出口商品检验局负责起草。本标准主要起草人:任世国、段文仲、郝冬生、白玉良。本标准系首次发布的行业标准。1范围

中华人民共和国进出口商品检验行业标准出口油籽、坚果及坚果制品中

黄曲霉毒素的检验方法液相色谱法Method for the determination of aflatoxins in oilseeds, nuts and nut products for export-Liquid chromatographic methodSN0637-1997

本标准规定了出口油籽、坚果及坚果制品中黄曲霉毒素检验的抽样、制样和液相色谱测定方法。本标准适用于出口花生仁和杏仁中黄曲霉毒素B、B2、GI、G,的检验。2抽样和制样

2.1检验批

花生仁以不超过200t(2400袋)为一检验批;杏仁以不超过50t(625袋)为一检验批。同一检验批的商品应具有相同的特征,如包装、标记、产地、规格和等级等。2.2抽样数量

按式(1)计算抽样袋数:

全批袋数:

式中:N—全

a-抽样袋数。

注:a值取整数,小数部分向前进位为整数。2.3抽样工具

2.3.1取样铲或取样勺。

2.3.2盛样袋:可密封。

2.3.3分样板。

2.3.4分样布。

2.4抽样方法

2.4.1倒包抽样:从堆垛的各部位随机抽取2.2规定的应抽样袋数的10%(每批一般不少于3袋),将袋口缝线全部拆开,平置于分样布上,双手紧握袋底两角,提起约成45°倾角,倒拖约1m,使袋内货物全部倒出。查看袋内和袋间品质是否一致。确认情况正常后,用取样铲随机在各部位抽取样品,立即倒入盛样袋中。每袋抽取的样品数量应基本一致。2.4.2袋内取样:按2.2规定的应抽样袋数的90%,在堆垛四周上、中、下各层以曲线形走向随机抽取样袋。将所抽各袋拆开袋口缝线3~5针,用取样勺从开口处抽取样品。立即缝好袋口,并将所取样品倒入盛样袋中,每袋抽取样品数量应与2.4.1基本一致。每批所抽取的样品总量应不少于4kg。2.4.3大样缩分:合并倒包和袋内取样所取全部样品,倒于分样布上,用分样板按四分法分出样品不少中华人民共和国国家进出口商品检验局1997-08-15批准1998-01-01实施

SN 06371997

于2kg,倒入样品袋中,加封后标明标记,并及时送交实验室。2.5试样制备

2.5.1制样工具

2.5.1.1切碎机或粉碎机。

2.5.1.2筛子:2.0mm圆孔筛。

2.5.1.3分样板。

2.5.1.4盛样瓶:具塞广口瓶。

2.5.2制样方法

将所取样品,用四分法缩分出约200g。用切碎机或粉碎机将缩分出的样品全部切碎或粉碎成尺寸不大于1mm并通过2.0mm圆孔筛碎粒。充分混匀,均分成两份作为试样,分装于洁净的盛样瓶中,密封,标明标记。

2.6试样保存

将试样于一5℃以下避光保存。

注:在抽样及制样的操作过程中,必须防止样品受到污染或发生残留物含盘的变化。3测定方法

3.1方法提要

试样中的黄曲霉毒索B、B2、G、G用三氯甲烷提取,提取液经弗罗里硅土柱净化,浓缩,定容。溶液用柱后衍生-液相色谱荧光检测器法测定,外标法定量。3.2试剂和材料

除另有规定外,所用试剂均为分析纯,水为蒸馏水。3.2.1三氯甲烷。

3.2.2丙酮。

3.2.3苯。

3.2.4乙腈。

3.2.5甲醇:紫外光谱纯。

5无水硫酸钠:600℃灼烧4h.贮于干燥器中备用。3.2.6

硅藻土:Celit545。

弗罗里硅土:60~100目,600℃灼烧4h,使用前于130℃活化3h,贮于干燥器中备用。3.2.8

3.2.9过溴化溴化吡啶(pyridiniumbromideperbromide)。3.2.10黄曲霉毒素BI、B2、GI、Gz标准品:纯度均≥99%。标准储备液:分别称取适量的黄曲霉毒素B,、BaG,G标准品,分别用少量苯溶解并用乙腈配3.2.11

成浓度为0.100mg/mL的标准储备液。3.2.12混合标准工作液:根据需要准确移取适量的黄曲霉毒素B,、B2、G,和G,的标准储备液,用乙睛稀释成适当浓度的混合标准工作液。3.3仪器和设备

3.3.1液相色谱仪并配有荧光检测器和柱后衍生化装置。3.3.2微量混和器。

3.3.3抽滤瓶。

3.3.4真空泵。

3.3.5旋转蒸发器。

3.3.6净化柱:玻璃柱,30cm×20mm(内径),用三氯甲烷湿法依次装入1.0g无水硫酸钠,0.7g弗罗里硅土,5.0g无水硫酸钠。

3.4测定步骤

3.4.1提取

SN0637-1997

称取约20g试样(精确至0.1g)于250mL具塞锥形瓶中,加入10mL水使试样充分湿润。加入5.0g硅藻土,并准确加入100mL三氯甲烷,于微量混和器上快速振荡5min。提取液经抽滤后过无水硫酸钠柱,收集50mL。

3.4.2净化

准确移取50.0mL上述提取液,注入弗罗里硅土净化柱中,用2×10mL三氯甲烷洗涤容器及玻璃柱,调节流速为2mL/min。待溶液全部流出后,用20mL三氯甲烷-甲醇(9十1)淋洗柱子,弃去全部流出液。用50mL丙酮-水(99+1)洗脱,收集洗脱液于心形瓶中。用旋转蒸发器于40℃水浴中减压蒸发至近干,再用氮气流吹干。准确加入2.0mL甲醇以溶解残渣,溶液供柱后衍生-液相色谱法测定。3.4.3测定

3.4.3.1色谱条件

a)色谱柱:15cm×4.6mm(内径),5μm,NucleosilCra柱,或相当者;b)流动相:甲醇-水(45+55),流速1.2mL/min;c)检测波长:激发波长365nm,发射波长450nm,d)柱后衍生剂:过溴化溴化吡啶水溶液(0.05mg/mL),流速0.48mL/min;e)反应管:30cm×0.25mm(内径),不锈钢管;f)柱温及反应管温度:35℃;

g)进样量20μL。

3.4.3.2色谱测定

根据样液中黄曲霉毒素B、Bz、G、G,的含量情况,选定峰高相近的混合标准工作液,混合标准工作液和样液中黄曲霉毒素BI、Bz、Gt、G?衍生物的响应值均应在仪器检测的线性范围内。对混合标准工作液和样液等体积参插进样测定。在上述色谱条件下,黄曲毒素BI、B2、Gl、G.衍生物的保留时间分别约为11.4min、9.3min、7.6min、6.4min。标准品的液相色谱图见附录A中图A1。3.4.4空白试验

除不加试样外,均按上述测定步骤进行。3.5结果计算与表述

用色谱处理机或按式(2)分别计算试样中黄曲毒素B、B,、G、Gz的含量:h.c.v

式中,X-—试样中黄曲霉毒素的含量,μg/kg;h--样液中黄曲霉毒素衍生物的峰高,mmh,一混合标准工作液中黄曲毒素衍生物的峰高,mm;一混合标准工作液中黄曲毒素的浓度,ng/mL;V—样液最终定容体积,mL

最终样液所代表的试样量,g。

注:计算结果需将空白值扣除。4测定低限、回收率

4.1测定低限

本方法测定低限:黄曲露毒素B,为0.75μg/kg;B,为0.90ug/kg;G为1.0μg/kgG,为1.Oμg/kg。

4.2回收率

SN0637-1997

杏仁和花生仁中黄曲霉毒素添加浓度及其回收率实验数据如下。4.2.1查仁中的回收率

黄曲霉毒素

4.2.2花生中的回收率

黄曲霉毒素

添加浓度(μg/kg)

添加浓度(μg/kg)

回收率

回收率

SN 06371997

附录A

(提示的附录)

标准品色谱图

注:色诺峰号1.2.3,4分别为黄曲群毒素Gz.G、B,、B,衍生物,保留时间分别为6.4min、7.6min、9.3min、11.4min。

黄曲爵毒素B、B2、GI、G.标准品衍生物的液相色谱图图A1

SN0637-1997

Foreword

This standard was drafted in accordance with the requirements of GB/T 1.1-1993\Directives forthe work of standardization-Unit l: Drafting and presentation of standards-Part l: General rulesfor drafting standards\ and presentation of standards and SN/T 0001-1995“General rules for draft-ing the standard methods for the determination of pesticide, veterinary drug residues and biotoxins incommodities for export\. The method of determination was drafted by referring to domestic and for-eign literatures through research, modification and verification, In addition, methods of sampling andsamplepreparation arealso specified in this standard.The limit of determination in this standard is defined on the basis of the curent internationalmaximum limit for aflatoxins B,,Bz,G,Gz in oil seeds, nuts and nut products and the sensitivity ofthe method.

Annex A of this standard is an informative annex.This standard was proposed by and is under the charge of the State Administration of Import andExport Commodity Inspection of the People's Republic of China.This standard was drafted by Hebei Import and Export Commodity Inspection bureau of the Peo-ple's Republic of China.

The main drafters of this standard are Ren Shiguo, Duan Wenzhong, Hao Dongsheng, Bai Yu-liang

This standard is a professional standard promulgated for the first time.Note:This English version,a translation fromn the Chinese text, is solely for guidance.6

Professional Standard of thePeople's Republic of Chinafor Import and Export Commodity InspectionMethod for the determination of aflatoxins in oilseeds,nuts and nutproducts forexport-Liquid chromatographic method1Scope

SN0637-1997

This standard specifies the method of sampling, sample preparation and determination by highperformance liquid chromatography of aflatoxins in oil seeds, nuts and nut products for export.This standard is applicable to the determination of aflatoxin Br, Bz, Gr,G,in peanut and almondforexport.

2 Sampling and samplepreparation2.1Inspectionlot

Each inspection lot, for peanut should not exceed 200 t (2 40o bags); for almond should not ex-ceed 50 t (625 bags).

The characteristics of the cargo within the same inspection lot, such as packing, mark, origin,specification and grade, should be the same.2.2Quantity of sampletaken

Calculate the number'of bags to be taken by formula (1):aN

N-total number of bags in a lot,a-number of bags to be taken.Note:If value a is with decimal,round off the decimal part,which is added as2.3 Sampling tools

2.3.1 Sampling shovel or ladle.2.3.2 Sampling bag, which can be sealed.2.3.3 Plate for quartering.

2.3.4 Cloth sheet:For sample quartering.2.4Samplingprocedure

(1)

y to the integral part of a.2.4.1 Sampling by emptying out: Draw 10o percent of the number of bags specified in 2.2 (not lessthan 3 bags) from differenit parts of the pile at random, Unseam and open the bag, and lay it on aclean cloth sheet. Grasp tight two corners of the bag bottom and raise up to an angle of 45'C, tugbackward for ca 1 m until all content of the bag is emptied out. Check whether the quality of theApproved by the State Administration ofImport and Export Commodity Inspection ofthePeople's Republic of China on Aug.15,1997Implemented from Jan.1,1998

SN0637-1997

goods are uniform within and between the bags. After confirming that the goods are in normal condi-tion, scoop up the sample from different parts of the out-poured content with a shovel,place in a sam-ple container promptly. The quantity of the sample drawn from each bag should be basically thesame.

2.4.2Sampling form inside the bag: Draw the samples from 90 percent of the number of bags speci-fied in 2. 2 as follows: Along the sine wave of the pile, draw the samples from the bags of the &pper,middle and lower parts around the pile at random. Partially unseam (3-5 stitches) the bags mouth,scoop out the sample with a sampling ladle at the bag opening. Promptly pour the sample into a sam-ple container and close the bag by seaming. The amount of the sample drawn from each bag should bebasically the same as in 2.4. 1.The total weight of the sample of each lot should be not less than 4 kg2. 4.3 Reduction of gross sample; Pour all the samples (from both 2. 4.1 and 2. 4. 2) onto a cleancloth sheet, reduce to not less than 2 kg with a plate by quartering. Place in a sample container, seal,label and send to the laboratory in time.2.5 Preparation of test sample2.5.1Sampling tools

2.5.1.1Sampleslicerorpulverizer.2.5.1.2 Seive:2.0 mm round-hole seive.2.5.1.3 Plate for quartering.2.5.1.4Samplecontainer:Widemouthbottle,withgroud stopper.2.5.2Procedure

Reduce the sample to ca 200 g by quartering.The sample is either sliced into thin pieces of lessthan I mm in size with a slicer or pulverized into granules with a pulverizer, let all pass through a2.o mm round-hole sieve. Mix thoroughly and divide into 2 equal portions, place in clean containersas the test samples, seal and label.2.6 Storage of test sample

The test sample shall be stored below -5C and kept away from light.Note: In the course of sampling and sample preparation, precautions must be taken to avoid the contamination orany factors which may cause the change of residue content.3Method of determination

3.1 Principle

The aflatoxins in the test sample are extracted with chloroform. The extract, after cleaning up bypass through a florisil column, is evaporated and made up to a definite volume. Determination is car-ried out by'post-column derivatization-high performance liquid chromatography with fluorescence detector, using external standard method.3.2 Reagents and materials

Unless otherwise specified, all the reagents should be analytically pure, \water\ is distilled wa-ter.

3.2.1 Chloroform.

3.2.2Acetone.

3.2.3 Benzene.

3.2.4Acetonitrile.

3.2.5Methanol:UVgrade.

SN 0637-1997

3.2.6 Anhydrous sodium sulfate: Ignite at 600C for 4 hours, keep in a desiccator.3.2.7Celite 545.www.bzxz.net

3.2.8Florisil,60—100mesh.Ignite at 600C for 4hours, and activate at 130C for3hours beforeuse,keep in a desiccator.

3.2.9 Pyridinium bromide perbromide.3.2.10AflatoxinB,Bz,Gr,Ggstandards:Purityall≥99%.3. 2. 11 Standard stock solution: Respectively weigh an adequate amount of each of aflatoxin Br, Br,Gr, Gz standard and dissolve each in a small amount of benzene. Dilute with acetonitrile to prepare thestandard stock solutions of o.1oomg/mL in concentration.3.2.12Mixed standard working solution: According to the requirment, pipet adequate amount ofaflatoxin Br, Bz, Gr, and Gz standard stock solutions, and dilute with acetonitrile to prepare a mixedstandard working solution of suitable concentrations.3.3Apparatus and equipments

3.3.1 Liquid chromatograph, equipped with fluorescence detector, and post-column derivatizer.3.3.2 Miniature mixer.

3.3.3 Suction bottle.

3.3.4Vacuumpump.

3.3.5Rotaryevaporator

3. 3. 6 Cleanup column; Glass column, 30 cmX20 mm (id), packed in sequence with 1.0 g of anhy-drous sodium sulfate, O.7 g of florisil and 5. g of anhydrous sodium sulfate by moistening with chlo-roform.

3.4 Procedure

3.4.1 Extraction

Weigh ca 20 g of the test sample (accurate to 0.1 g) into a 250 mL conical flask with stopper,add 10 mL of water to moisten the sample thoroughly.Add 5. 0 g of celite 545 and accurately add 100mL of chloroform, shake vigorously for 5 min on a miniature mixer. The extract, after filtered bysuction, is dehydrated by passing through an anhydrous sodium sulfate column, and 5o mL of the extract are collected.

3.4.2 Cleanup

Transfer exactly 50 mL of above extract into the packed cleanup column. Rinse the container andthe column with 2X10 ml of chloroform (adjusting theflow rate to 2 mL/min).When the solutiondrains out, wash the column with 20 mL of chloroform-methanol (9+1). Discard all of the above ef-fluents. Then elute with 50 mL of acetone-water (99+1), and collect the eluate into a heart-shapedflask. Evaporate to near dryness with a rotary evaporator under reduced pressure at 4o'C bath temper-ature and evaporate to dryness under a stream of nitrogen. Exactly add 2. O mL of methanol to dis-solve the residue, and the solution is used for liquid chromatographic determination.3.4.3Determination

3.4.3.1 HPLC operating conditiona)Column:15cmX4.6mm(id),5μm,Nucleosil Cig column,or equivalent;b)Mobilphase:methanol-water(45+55),1.2mL/min;c)Fluorescence detector:Excitation wavelength 365 nm, emission wavelength 450 nm;d) Reagent for post-column derivatization: Pyridinium bromide perbromide aqueous solution,9

SN 0637-1997

0.05mg/mL,flowrate:0.48mL/min,e)Reaction tube:30 cmXo.25mm (id),stainless steel tube;f) Column and reaction tube temperature: 35C;g)Injectionvolume:20 μL.

3.4.3.2HPLC determination

According to the concentrations of aflatoxin Br, Bz, G, and Gz in the sample solution, select themixed standard working solution with the similar peak heights to those of sample solution. The re-sponses of aflatoxin Br,Bz,G, and G,derivatives in the standard working solution and the sample so-lution should be within the linear range of the instrumental detection. The standard working solutionshould be randomly injected in-between the injections of sample solution of equal volume, Under theabove HPLC operating condition, the retention times of aflatoxin Br, Bz, G, and G, derivatives are11. 4, 9. 3, 7.6 and 6. 4 min respectively. For liquid chromatogram of the standards see fig.A1 inannex A.

3.4.4 Blank test

The operation of blank test is the same as that described in the method of determination, but withthe omission of sample addition.3. 5 Caleulation and expression of the resultsCalculate the results by LC data precessor or according to formula (2):X

X-thecontentofaflatoxinB,,Bz,G,orGzinthetest sample,μg/kg(2)

h-thepeak height of aflatoxin B,Bz,G,or Gzderivativein the sample solution,mm;h,the peak height of aflatoxin Br, Bz, G, or G2 derivative in the mixed standard working solu-tion,mm;

c--the concentration of aflatoxin B,Bz,G, or G, in the mixed standard working solution,ng/mL

V--the final volume of sample solution,mL,m-the corresponding mass of test sample in the final sample solution,g.Note: The blank value should be subtracted from the above result of calculation.4 Limit of determination and recovery4.1 Limit of determination

The limits of determination of this method are 0. 75 μg/kg, 0. 90 μg/kg, 1. 0 μg/kg and 1. Oμg/kgfor aflatoxinB,Ba,G,and G respectively4.2Recovery

According to the experimental data, the fortifying concentrations of various aflatoxins and theirrecoveries in almond and peanut are as follows.4.2.1 In almond

Aflatoxin

Fortifyingconcentration(μg/kg)0.75

Recovery

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

标准图片预览:

- 其它标准

- 热门标准

- 商检行业标准(SN)

- SN/T3413-2012 欧洲散白蚁检疫鉴定方法

- SN/T0259-93 出口直接辐射式电动锥形扬声器检验规程

- SN/T3720.1-2013 进口泵检验规程第1部分:冷水(热泵)机组能效

- SN/T4322-2015 食品接触材料高分子材料双酚A残留量的测定酶联免疫法

- SN/T4629-2016 检疫性有害生物凭证标本核酸制备、保存与管理规范

- SN/T1933.1-2007 食品和水中肠球菌检验方法 第1部分:平板计数法和最近似值测定法

- SN/T3987-2014 牛海绵状脑病特殊风险物质实时荧光RT-PCR检测方法

- SN/T3297-2012 植物种质资源鉴定方法玉米的鉴定

- SN/T1931.1-2007 进出口机织物检验规程 第1部分:通则

- SN/T1073-2002 出口瓶装酱菜检验规程

- SN0530-1996 出口肉中呋喃唑酮残留量的检验方法液相色谱法

- SN/T2552.6-2010 乳及乳制品卫生微生物学检验方法 第6部分:柠檬酸杆菌检验

- SN/T1310-2011 动物结核病检疫技术规范

- SN/T3241.7-2013 进出口家用及类似用途电器检验技术要求 第7部分:储水式电热水器的能效

- SN/T1581-2014 对境外繁育农作物种子检疫规程

- 行业新闻

请牢记:“bzxz.net”即是“标准下载”四个汉字汉语拼音首字母与国际顶级域名“.net”的组合。 ©2025 标准下载网 www.bzxz.net 本站邮件:bzxznet@163.com

网站备案号:湘ICP备2025141790号-2

网站备案号:湘ICP备2025141790号-2