- 您的位置:

- 标准下载网 >>

- 标准分类 >>

- 商检行业标准(SN) >>

- SN/T 1477-2004 进出口食品中多效唑残留量检验方法

标准号:

SN/T 1477-2004

标准名称:

进出口食品中多效唑残留量检验方法

标准类别:

商检行业标准(SN)

标准状态:

现行-

发布日期:

2004-11-17 -

实施日期:

2005-04-01 出版语种:

简体中文下载格式:

.rar.pdf下载大小:

725.46 KB

部分标准内容:

本标准的附录A为资料性附录。

本标推出国家认证认可监督管埋委员会提出并归口。本标摊出中国检验检疫科学研究院负贵起草。本标主要起草人:白桦、邱月明、郝楠、张青本标准系首次发布的出人境检验检疫行业标准。SN/T 1477—2004

1范围

进出口食品中多效唑残留量检验方法,SN/T 1477—2004

本标准规定了进出口食品中多效唑残留量检验的抽样、制样和气相色谱-质谱测定方法。本标推适用于进出口粮谷、水果中多效唑残留量的检验。2抽样和制样

2.1粮谷样品

2.1.1检验批

以不超过4000袋(200)为一检验批同一·检验批的商品应其有相同的特征,如包装标记、产地、规格和等级等。2.1.2抽样数量bzxz.net

按批总袋数的平方根式(1)门抽取:a=VN

武中:

N-.·-全批袋数;

抽样袋数(α值取整数,小数部分向前逊位为整数)。2.1.3抽样工具

a)金属单管取样器:不锈钢管,企长55cm(包括手柄),直径1.5cml,构槽长度应超过袋对角线长度的一半;

b)取样铲;

c)分样板;

d)样品简(袋):可密封:

e)分样布或适用铺垫物

2.1.4抽样方法

2.1.4.1倒包抽样

从垛的各部位随机抽取2.1.2规定的应抽样件数的10%(每批-股不少丁3袋),将袋几缝线全部拆开,平置于分样布或其他洁净的铺挚物上,双手紧握底两角,提起约成145\倾角·倒拖约1m,使袋内货物企部倒出。查看内和袋间品质是否均匀。确认情况正常后,用取样随机在务部位谢取样品:立即将样品倒人盛样容器内。每袋抽取样品数量应苯一致。2、1.4.2袋内抽样

按2.1.2规定的应抽样袋数的90%,在堆垛四周上,中、下各层以曲线形走问随机抽取。将取样器管槽朝下,从每袋一角依斜对角方间插人袋内.然后将管槽旋转朝上·抽出取样器,立即将样品倒人盛样容器内,每袋抛取样品数量应与2.1.1.1基本一致。每批样品总量应不少于kg。

2.1.4.3大样缩分

集中袋内和倒包抽样所取全部样品,倒于分样布王,用分样板按叫分法缩分出样品不少于2k名·盛于样品简内,加封后标明标记并及时送交实验案。2.1.5试样制备

将样品按四分法缩分出约1kg,全部磨碎并通过20日筛,混勾,均分成两份试样,装人洁净的容器1

SN/T 1477—2004

内,密封,标明标记。

2.1.6试样保存

将试样于一5℃以下避光保存。

2.2水果样品

2.2.1检验批

以不超过 1 500 件为一检验批。同-检验批的商品应具有相同特征,如包装、标记、产地、规格和等级等.2.2.2抽样数量

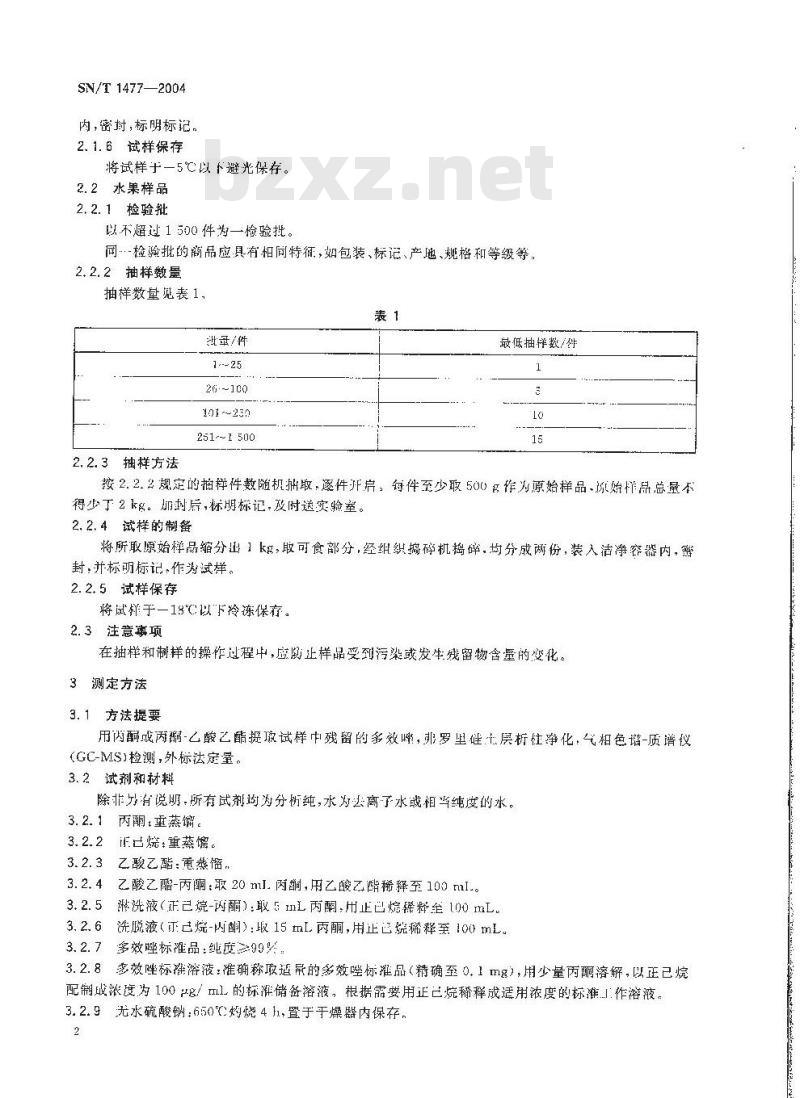

抽样数量见表1,

26·~100

101-~230

251-~1 500

2.2.3抽样方法

最低抽样数/件

按2.2.2规定的拍样件数随机洲取,逐件开启,每件至少取500名作为原始样品、源赔样品总量不得少丁2k。加封后,株明标记.及附送实验室。2.2.4试样的制备

将所取原始品缩分出1kg,取可食部分,经组织捣碎机碎,均分成两份,装入洁净容器内,密封,并标明标记,作为试样。

2.2.5试样保存

将试样于一18℃以下冷冻保存。2.3注意事项

在抽样和制样的操作过程中,盛朗止样品受到污染或发生残留物含量的变化。3测定方法

3.1方法提要

用闪酶或丙斓-乙酸乙酯提取试样中残留的多效哗,卵罗里硅十层析柱净化,气相色谐-质谱仪(GC-MS)检测,外标法定量。

3.2试剂和材料

除非另有说明,所有试剂均为分析纯,水为去离子水或相当纯度的水。3.2.1丙酮:重蒸馏。

3.2.2正F巴烧重蒸馏。

3.2.3乙酸乙酯:重蒸馅.

3.2.4乙酸乙-丙酮:取20ml.丙酮,用乙酸乙酯稀释至100ml。3.2.5淤洗液(正已烷-闪酮)取5mL丙酮,用正巴烷释垒100mL。3.2.6洗脱液(下己烷-内酮):取15mL丙酮,用止巴烷稀释至100mL3.2.7多效唑标雅品:纯度含99%3.2.8效唑标准浴液:准确称取适晟的多效唑标品(精确至0.1mg),用少量丙酮溶解,以正已烷配制成浓度为1002g/mL的标准储备溶液,根据需要用正已烷稀释成适用浓度的标准1.作溶液。3.2.9无水硫酸钠:650C灼烧4h.置于于燥器内保存,2

SN/T 1477---2004

3.2.10弗罗单硅土(Flarisil),60 月~100 目,层析用。110'℃烘烤4 h,置于干燥器内保存。3.3仪器和设备

3.3.1气树色谱-质谱仪:

3.3.2旋转裁发器。

3.3.3振荡器.

3.3.4维形瓶:具磨口塞,250ml3.3.5梨形瓶:250mL.

3. 3.6净化柱:250 mmX.10 mm(内径)玻璃仕,杜底填脱脂棉,依次「法装入约2 cm高的光水硫酸钠、2兆罗里硅土和药2cI高的无水硫酸钠。3. 4定步骤

3.4.1提取

粮容样品:称取约10g试样(精确系1ng)于锥形瓶中,加人30 imL丙酮,手振荡器[:提取30Ini,过燃,滤滋收策丁25心mL形瓶中,重复上述提取操作,用20mL丙酮分两次洗涤锥形瓶及滤渣,合并滤液于梨彤瓶中,于旋转蒸发器将滤液浓缩至近干。水果样酯称收药10名试样(精确卒1加g)于链形瓶中,50mL艺懿艺酯丙霾(3.2.4),于振荡器卜提敢1b。滤,滤液败集于25心 mI.梨形瓶中,滤渣再加 30 L乙酸乙酯-丙酮(3.2.4)提取30 m1,过滤,用20ml.乙酸乙酯-内嗣(3.2.4):分两次洗涤罐形瓶及滤渣。合并滤液于梨形瓶中,于巅转蒸发器将滤液浓缩至近下:

3.4.2净化

用10 mL正已烷预淋洗层析杜:用淋洗液(3.2.5)溶解娥渣(3.4.1),并转移至层析柱(3.3.6)中。用40ml淋洗液(3.2.5)进行淋洗(流速1.5L/1I111).弃丢。用30m.洗脱液(3.2.t)进行洗脱(流1,5 ml/min),收集洗脱液。洗脱液于旋转蒸发器浓缩至近干,用氮气吹/.用正已烷解并定容,供气相色谱-质谱测定。

3.4.3测定

3.4.3.1器条件

a)色谱杜;HP-530 m×0.25 mm(内径)× 0.25 m(膜厚)。l)色谱柱温度:100℃-20℃/min→220℃-5℃/min-250℃(15 min)进样口温度:280℃。

d)源温:230℃。

传输线温度:280℃。

离于源;EI源。

测定方式:选择离子监测方式

选释监测离子(m/z):125、167、236。h)

载气:氮气,纯度 99.999%,流速1.0mL/nih。j)过样方式:无分流逛样,l min后并,k)进样量,l ul。

3,4. 3.2色谱-质谱测定

根据样液中多效唑的含量,选定浓度相近的标准工作溶液,待测样液中多效唑的响应值应在仪器检测的线性范闹内(0.05 ng~5.0 ng)。对标推工作溶液及样液(3,4.2)等体积参插进样测定。在上述仪器条件下(3.4.3.1)多效保留时间约为10.7min,气相色谱质谱总离子流图参见谢录A图A.1。3、4,3.3色谱-质谱确证

符合下列条件,即可确定样品中含有多效唑:在保留时间10.7min附近有峰山现,选定的质谱碎片离子在样品的选择离了质谱图中都能出现样品峰的质谱图中各碎片离子的相对卡度与标准样品质谱3

SN/T1477—2004

图中各碎片离子的相对半度一致,气相色谱-质谱图参见附录A图A.2.3.4.4空白试验

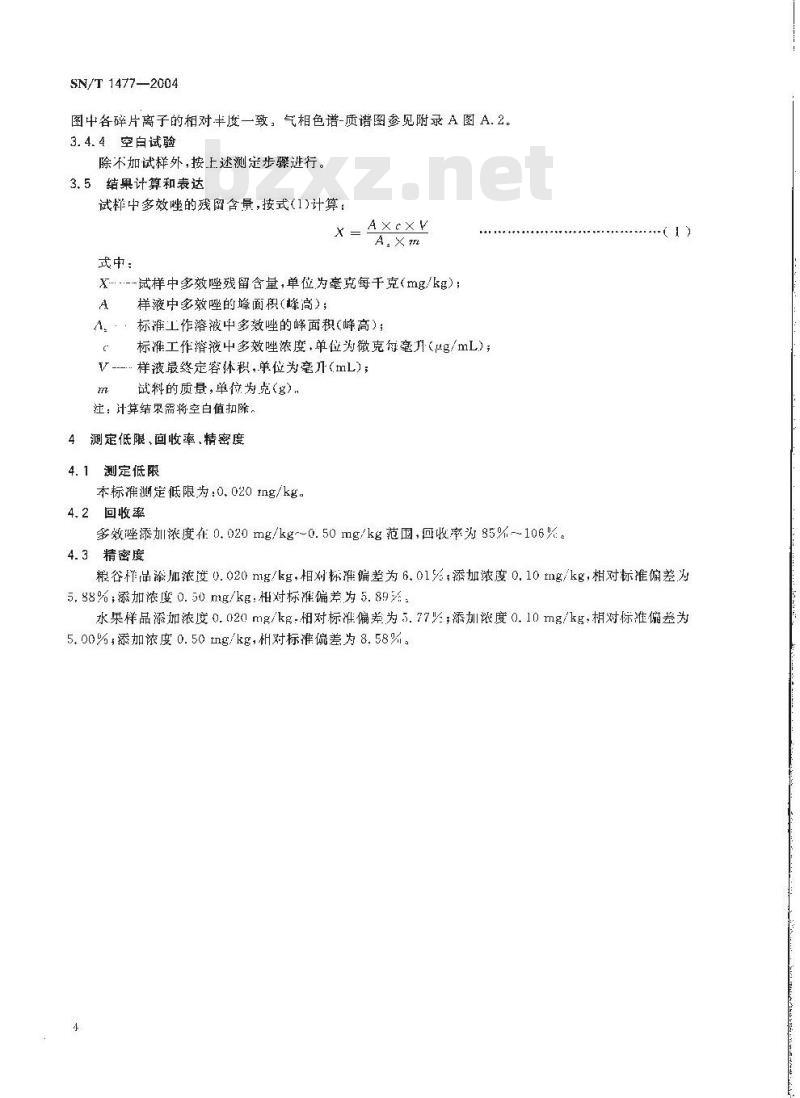

除不加试样外,按上述测定步骤避行。3.5结果计算和表达

试样中多效唑的残留含量,按式(1)计算:AXXV

式中:

X-试样中多效唑残留含量,单位为毫克每千克(mg/kg);A

样液中多效唑的峰面积(峰高);

A:标准工作溶液中多效唑的峰面积(峰高);标准工作溶液中多效唑浓度,单位为微克每毫升(ug/mL);V-样液最终定容体积,单位为毫升(mL);试料的质量,单位为点(么),注:计算结果需将空白值扣除。4测定低限、回收率,精密度

4.1测定低限

本标准测定低限为:0.020 tng/kg,4.2回收率

多效唑添加浓度在0.020mg/kg-~0.50mg/kg范围,回收率为85%-~106%。4.3精密度

粮谷样品添加浓度0.020mg/kg,相对标准偏差为6.01%,添加浓度0.10mg/kg,相对标准偏差为5.88%;添加浓度0.50 mg/kg:相对标摊偏差为5.89%:水果样品添加浓度0.020 mg/kg:对标准偏差为5.77%;添加浓度0.10 mg/kg相对标准偏差为5.00%,添加浓度0.50 g/kg,相对标准偏差为8.58%。10

附录A

(资料性附录)

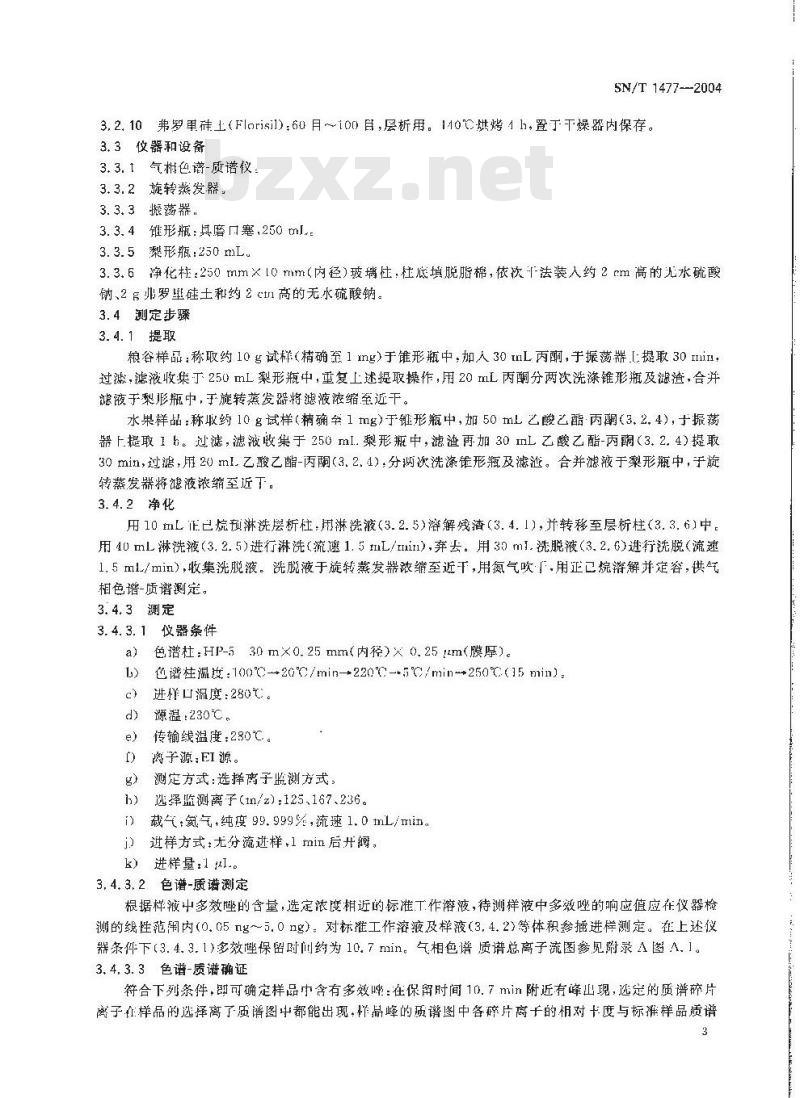

标准物气相色谱-质谱图

t/imen

多效唑标准品气相色谱-质谱总离子流图(TIC)236

Il ior+ pall

20Y218

多效唑标准品质谱图

SN/T1477—2004

SN/T 1477—2004

Foreword

Annex A of this standard is an informative annex.This standard was proposed by and is under the charge of Certification and Accreditation Administration of P. R. c

This standard was drafted by China Academy of Inspection and Quarantine,This standard was mainly drafted by Bai Hua, Qiu Yusming, Hao Nan, Zhang Qing.This standard is a professional standard promulgated for the first tirneNote: This English version, a translation from the China text, is solely for guidance.1

Inspection of paclobutrazol

SN/T 1477—2004

residues in food for import and exportThis stancard specifies the methods of sampling, sample preparation and determination ofpaclobutrazol residues by Gc-Ms in food for import and export.This standard is applicable to the determination of pacfobutrazol residuas in cereals and fruits for im-port and export.

Sampling and Sample preparation2

2. 1 Cereal sample

2. 1. 1Inspection lot

Eachinspectionlotshouldnotexceed4000bags(200t).The characteristics of the cargo within the same inspection lot, such as packing, mark, origin, spaci-fication, grade etc. ,should be the sarne.2. 1. 2Quantity of sample takenThe number of bags to be sampled shall be catculated according to the formula (1) :aN

N--total number of bags in a lot;a-number of bags to be taken (if value a is with decimal,round off the decimal part, which isadded as unity to the integral part of a).2. 1. 3Sampling tools

Metallic sampler: Stainless steel tube, length (including handle): 55 cm; diameter:1, 5 cm:a)

groove length: longer than half the diagonal length of the bag;b)

2. 1. 4. 1

Sampling shovel;

Plate for quartering:

Sample can (bag). which can be sealed:Cloth (or other suitable material) sheet: For sample dividing(quartering),Sampling procedure

Sampling by emptying out: Draw 10 percent of the number of bags specified in 2. 1. 2 (not7

SN/T1477—2004

less than 3 bags ) at any part of the pile at random. Unseam and open the bag, and lay it on a cleancloth sheet(or other clean sheet), Grasp tight two corners of the bag bottom anid raise up to angle of45°, tug backward for ca 1 m until ail content of the bag is emptied out. Check whether the qualityof the goods is uniform within and between the bags. After confirming the goods are in normal con-dition, scoop up the sample from different parts of the out- poured content with a shovel, and placein a sample container promptiy. The quantity of the sample drawn fram each bag should be basicallythe same.

2. 1.4. 2Sampling from inside the bags: Draw the samples from 90 percent of the number of bagsspecified in 2. 1.2 as fallaws: Along the sine wave of the pile. draw samples from the bags af theupper, middle and lower parts of the pile at random. Insert the sampler, with its groove facingdawnward, diagonaly inta each bag. then turn the sampler by 180',draw out the sampler, promptlypour the sample into a container. The quantity of the sample drawn from each bag shall be basicallythe same as in 2. 1. 4. 1

The total weight of the representative sample of each lot should be not less thar 4 kg.2. 1.4.3Reductian of gross samplePour all the samples (from both 2. 1. 4. 1 and 2. 1. 4. 2) on a clean sheet, reduce to not less than 2 kgwith a plate by quartering. Piace in a sample container, seal, label and send to the laboratory in time.2. 1. 5 preparation of test sampleReduce the sample to ca 1 kg by quartering: grind thoroughly and let pass through a 20 mesh sieve,mix thoroughly and divide into 2 equal portions, place in clean containers as the test samples, sealand label.

2. 1.6 Storage of test sampleThe test sample shall be stored below -5 ℃ and kept away from light.2. 2Fruit sample

2.2.1Inspection lot

The quantity of an inspection lot should not be more than 1 5oo packages.The characteristics of the cargo within the same inspection lot, such as packing, mark, origin, gradeand specification, shonld be the same.2. 2. 2 Quantity of sample takenQuantity of sample taken see Table 1.Table 1

Number of packages in each inspection lot1~25

26~100

101~250

251~1500

Minimum number af packages to be taken5

2. 2. 3 Sampling procedure

SN/T 1477—2004

A number of packages specified in 2. 2. 2 are taken at random and opened one by one. The sampleweight taken as the primary sample from each package should be at least 50o grams, The totalweight of all primary samples should not be less than 2 kg. which should he sealed, labeled and sentto laboratory in time

2.2.4Preparation of test sampleThe combined primary sample is reduced to 1 kg: the adible portions are blended. and then dividedinto two equal portions. Each portion is placed in a clean container as the test sample, which is thensealed and labeled.

2.2.5Storage of test sample

The test samples shonld be stored below - 18℃.2.3Attention

In the course Of sampling and sample preparation. precaution should be taken to avoid contaminationor any factors which may cause the change of residue content3Method of determinatian

3, 1 Princinle

Paclobutrazol is extracted from sarnple with acetone or acetic acetate-acetone. After evaporation afsolvents, the residue is dissolved in n-hexane-acetone and then cleaned by Florisil column, The elu-tion is concentrated and the residue is redissolved in n-hexane, Paclobutrazol is determinated by GC-Ms and quantified from calibration curve.3,2Reagents and materials

Unless specifically mentioned, all reagents used should be analytical grade , \ water\ jsdeionized water.

Acetone: redistilled.

n-Hexane: redistilled.

Acetic acetate: redistilled.3.3.4

Acetic acetate -Acetone: 20 mL of acetone diluted to 100 ml with acetic acetate.3. 2. 5 Wash soluition (n-Hexane-Acetone): 5 mL of acetone diluted to 100 mL with n-hexane.3. 2. 6 Elution (n-Hexane-Acetone) : 15 mL of acetone diluted to 100 mL with n-hexane.9

SN/T1477—2004

3.2.7Paclobutrazol standard: Purity99 %.3. 2. 8Paclobutrazol standard solution; Certain amount of paclobutrazol weighed accurately(accu-rate to 0. 1 mg) and dissolved in n-hexane to prepare 100 μg/ mL standard stock solution, and dilutedto suitable concentration with n-hexane as standard working solution.3. 2. 9Anhydrous sodium sulfate: tgnited at 650'℃ for 4 h, and stored in desiccator3. 2. 10 Florisil: 60 ~100 mesh, chromatographic grade, heated at 140℃ for 4 h, and stored in desic.cator.

Apparatls and equipment

Gas Chramatograph-Mass Spectrometry.Rotary evaporator.

Conicalflask:25oml.withground-giassstopper.3.3.5

Pear-shaped flask: 250 mL.

Florisil column:250 mm×10mm glass calumn filead with 2 cm of anhydrous sodium、2 g of3.3.6

Florisil and 2 cm of anhydrous sodiuin.3.4 procedure

3.4.1Extraction

Cereals sample: 10 g (accurate to 1 rmg) of test sample is weighed in a 250 mL conical flask,30 ml. ofacetone is added arid shaked for 30 min. The extraction is repeated. Then filtered into a 250 mi.pear-shaped flask. The conical flask and filter cake are rinsed twice with 20 ml of acetone. Ali acetonesolutions are combined in the pear-shaped flask, evaporated to nearly dry in a water bathunder 40℃.

Fruits sampie: 10 g (accurate to 1 mg) of test sample is weighed in a 250 mL conical flask.50 mL ofacetic acetate-acetone(3.2.4) is added and shaked for1h.The extraction is repeated with 30mLofacetic acetate -acetone(3, 2. 4) and shaked for 30 min. Then filtered into a 250 ml pear-shaped flask.The conical flask and filter cake are rinsed twice with 20 mL of acetic acetate -acetone (3. 2. 4) : Alsoiutions are combined in the pear-shaped flask, evaporatect to nearly dry in a water bath under 40 3. 4. 2 Clean up

The above dried extraction is redissolved in 5 mL of n-hexane-acetcne (3. 2. 5) by a few times andtransferred to the Florisil colurmn (3. 3. 6). The column is washed with 40 mL of n-hexane-acetone0

SN/T1477—2004

(3. 2. 5), then eluted with 30 mL of n-hexane-acetone (3. 2. 6). The eluent is collected into pear-shaped flask and evaporated in a water bath under 4o'c , then dried with a gentle nitrogen stream.The residue is redissolved in 1 mL of n-hexane.3. 4. 3Determination

3, 4. 3. 1 Operating conditiansa)

Colurmn: HP-5 30 m × 0.25 mm (i. d. ) x 0. 25 μm (film thickness) or equiyalent.Coiurmntemperature:100℃-→20℃/min-220℃→+5℃/min-+250℃(15min).Injection temperatire: 28a'c.Source temperature: 230'c.

Interfacetemperature:280'c.

lon source: Et.

Derermination mode: selected iori rronitoring.Selected ions(m/2) : 125,167,236.Cartier gas: He, Purity ≥99. 999% . flow rate: 1.0 mL/min.Injection mode: Splitless. valva activated at 1 min.k) Injection volurne: 1 μL.3.4. 3.2GC-Ms determination

Inject accurately equal amount (1 μL)of the paciobutrazo! standard working soiution and sampling so.lution (3.4.2)into Gc-Ms respectiveiy,the responses of tha paciobutrazol in the standard workingsolution and sampie soiution should be similar and must be within the ltinear range ot the detector(0. 05 ng -~5, 0 ng). Sample solutions should be injected in betwsen standard solutions. The retention time of pactobutrazol is about t0. 7 min under the above conditions (3. 4, 3. 1). Gc-Ms Chromat-ogram of paclobutrazoi standard is Fig. A, 1.3. 4. 3. 3 GC-MS tonfirmationA peak couid be identifiad as paclobutrazel if it is in accordance with the following coridition:The peak has a retention time of about 1o, 7 min, the selected ions monitored could be found in themass spectrum of the peak, and the relative abundance of the segments of the sample peak is com-patible to those of the standard peak. Mass specirum of paclobutrazol standare is Fig.A.2.3. 4. 4Blank test

The operation of blank test is the same as above, except without sample.3. 5Calculatian and expresssion of resultThe content of paclobutrazal is caiculated by the following formnula (2) :X=

X-the residue content of paclobutrazol in test sample. mg/kg;A-- -peak area (or peak height ) of paclobutrazof in sample solution:(2)

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

本标推出国家认证认可监督管埋委员会提出并归口。本标摊出中国检验检疫科学研究院负贵起草。本标主要起草人:白桦、邱月明、郝楠、张青本标准系首次发布的出人境检验检疫行业标准。SN/T 1477—2004

1范围

进出口食品中多效唑残留量检验方法,SN/T 1477—2004

本标准规定了进出口食品中多效唑残留量检验的抽样、制样和气相色谱-质谱测定方法。本标推适用于进出口粮谷、水果中多效唑残留量的检验。2抽样和制样

2.1粮谷样品

2.1.1检验批

以不超过4000袋(200)为一检验批同一·检验批的商品应其有相同的特征,如包装标记、产地、规格和等级等。2.1.2抽样数量bzxz.net

按批总袋数的平方根式(1)门抽取:a=VN

武中:

N-.·-全批袋数;

抽样袋数(α值取整数,小数部分向前逊位为整数)。2.1.3抽样工具

a)金属单管取样器:不锈钢管,企长55cm(包括手柄),直径1.5cml,构槽长度应超过袋对角线长度的一半;

b)取样铲;

c)分样板;

d)样品简(袋):可密封:

e)分样布或适用铺垫物

2.1.4抽样方法

2.1.4.1倒包抽样

从垛的各部位随机抽取2.1.2规定的应抽样件数的10%(每批-股不少丁3袋),将袋几缝线全部拆开,平置于分样布或其他洁净的铺挚物上,双手紧握底两角,提起约成145\倾角·倒拖约1m,使袋内货物企部倒出。查看内和袋间品质是否均匀。确认情况正常后,用取样随机在务部位谢取样品:立即将样品倒人盛样容器内。每袋抽取样品数量应苯一致。2、1.4.2袋内抽样

按2.1.2规定的应抽样袋数的90%,在堆垛四周上,中、下各层以曲线形走问随机抽取。将取样器管槽朝下,从每袋一角依斜对角方间插人袋内.然后将管槽旋转朝上·抽出取样器,立即将样品倒人盛样容器内,每袋抛取样品数量应与2.1.1.1基本一致。每批样品总量应不少于kg。

2.1.4.3大样缩分

集中袋内和倒包抽样所取全部样品,倒于分样布王,用分样板按叫分法缩分出样品不少于2k名·盛于样品简内,加封后标明标记并及时送交实验案。2.1.5试样制备

将样品按四分法缩分出约1kg,全部磨碎并通过20日筛,混勾,均分成两份试样,装人洁净的容器1

SN/T 1477—2004

内,密封,标明标记。

2.1.6试样保存

将试样于一5℃以下避光保存。

2.2水果样品

2.2.1检验批

以不超过 1 500 件为一检验批。同-检验批的商品应具有相同特征,如包装、标记、产地、规格和等级等.2.2.2抽样数量

抽样数量见表1,

26·~100

101-~230

251-~1 500

2.2.3抽样方法

最低抽样数/件

按2.2.2规定的拍样件数随机洲取,逐件开启,每件至少取500名作为原始样品、源赔样品总量不得少丁2k。加封后,株明标记.及附送实验室。2.2.4试样的制备

将所取原始品缩分出1kg,取可食部分,经组织捣碎机碎,均分成两份,装入洁净容器内,密封,并标明标记,作为试样。

2.2.5试样保存

将试样于一18℃以下冷冻保存。2.3注意事项

在抽样和制样的操作过程中,盛朗止样品受到污染或发生残留物含量的变化。3测定方法

3.1方法提要

用闪酶或丙斓-乙酸乙酯提取试样中残留的多效哗,卵罗里硅十层析柱净化,气相色谐-质谱仪(GC-MS)检测,外标法定量。

3.2试剂和材料

除非另有说明,所有试剂均为分析纯,水为去离子水或相当纯度的水。3.2.1丙酮:重蒸馏。

3.2.2正F巴烧重蒸馏。

3.2.3乙酸乙酯:重蒸馅.

3.2.4乙酸乙-丙酮:取20ml.丙酮,用乙酸乙酯稀释至100ml。3.2.5淤洗液(正已烷-闪酮)取5mL丙酮,用正巴烷释垒100mL。3.2.6洗脱液(下己烷-内酮):取15mL丙酮,用止巴烷稀释至100mL3.2.7多效唑标雅品:纯度含99%3.2.8效唑标准浴液:准确称取适晟的多效唑标品(精确至0.1mg),用少量丙酮溶解,以正已烷配制成浓度为1002g/mL的标准储备溶液,根据需要用正已烷稀释成适用浓度的标准1.作溶液。3.2.9无水硫酸钠:650C灼烧4h.置于于燥器内保存,2

SN/T 1477---2004

3.2.10弗罗单硅土(Flarisil),60 月~100 目,层析用。110'℃烘烤4 h,置于干燥器内保存。3.3仪器和设备

3.3.1气树色谱-质谱仪:

3.3.2旋转裁发器。

3.3.3振荡器.

3.3.4维形瓶:具磨口塞,250ml3.3.5梨形瓶:250mL.

3. 3.6净化柱:250 mmX.10 mm(内径)玻璃仕,杜底填脱脂棉,依次「法装入约2 cm高的光水硫酸钠、2兆罗里硅土和药2cI高的无水硫酸钠。3. 4定步骤

3.4.1提取

粮容样品:称取约10g试样(精确系1ng)于锥形瓶中,加人30 imL丙酮,手振荡器[:提取30Ini,过燃,滤滋收策丁25心mL形瓶中,重复上述提取操作,用20mL丙酮分两次洗涤锥形瓶及滤渣,合并滤液于梨彤瓶中,于旋转蒸发器将滤液浓缩至近干。水果样酯称收药10名试样(精确卒1加g)于链形瓶中,50mL艺懿艺酯丙霾(3.2.4),于振荡器卜提敢1b。滤,滤液败集于25心 mI.梨形瓶中,滤渣再加 30 L乙酸乙酯-丙酮(3.2.4)提取30 m1,过滤,用20ml.乙酸乙酯-内嗣(3.2.4):分两次洗涤罐形瓶及滤渣。合并滤液于梨形瓶中,于巅转蒸发器将滤液浓缩至近下:

3.4.2净化

用10 mL正已烷预淋洗层析杜:用淋洗液(3.2.5)溶解娥渣(3.4.1),并转移至层析柱(3.3.6)中。用40ml淋洗液(3.2.5)进行淋洗(流速1.5L/1I111).弃丢。用30m.洗脱液(3.2.t)进行洗脱(流1,5 ml/min),收集洗脱液。洗脱液于旋转蒸发器浓缩至近干,用氮气吹/.用正已烷解并定容,供气相色谱-质谱测定。

3.4.3测定

3.4.3.1器条件

a)色谱杜;HP-530 m×0.25 mm(内径)× 0.25 m(膜厚)。l)色谱柱温度:100℃-20℃/min→220℃-5℃/min-250℃(15 min)进样口温度:280℃。

d)源温:230℃。

传输线温度:280℃。

离于源;EI源。

测定方式:选择离子监测方式

选释监测离子(m/z):125、167、236。h)

载气:氮气,纯度 99.999%,流速1.0mL/nih。j)过样方式:无分流逛样,l min后并,k)进样量,l ul。

3,4. 3.2色谱-质谱测定

根据样液中多效唑的含量,选定浓度相近的标准工作溶液,待测样液中多效唑的响应值应在仪器检测的线性范闹内(0.05 ng~5.0 ng)。对标推工作溶液及样液(3,4.2)等体积参插进样测定。在上述仪器条件下(3.4.3.1)多效保留时间约为10.7min,气相色谱质谱总离子流图参见谢录A图A.1。3、4,3.3色谱-质谱确证

符合下列条件,即可确定样品中含有多效唑:在保留时间10.7min附近有峰山现,选定的质谱碎片离子在样品的选择离了质谱图中都能出现样品峰的质谱图中各碎片离子的相对卡度与标准样品质谱3

SN/T1477—2004

图中各碎片离子的相对半度一致,气相色谱-质谱图参见附录A图A.2.3.4.4空白试验

除不加试样外,按上述测定步骤避行。3.5结果计算和表达

试样中多效唑的残留含量,按式(1)计算:AXXV

式中:

X-试样中多效唑残留含量,单位为毫克每千克(mg/kg);A

样液中多效唑的峰面积(峰高);

A:标准工作溶液中多效唑的峰面积(峰高);标准工作溶液中多效唑浓度,单位为微克每毫升(ug/mL);V-样液最终定容体积,单位为毫升(mL);试料的质量,单位为点(么),注:计算结果需将空白值扣除。4测定低限、回收率,精密度

4.1测定低限

本标准测定低限为:0.020 tng/kg,4.2回收率

多效唑添加浓度在0.020mg/kg-~0.50mg/kg范围,回收率为85%-~106%。4.3精密度

粮谷样品添加浓度0.020mg/kg,相对标准偏差为6.01%,添加浓度0.10mg/kg,相对标准偏差为5.88%;添加浓度0.50 mg/kg:相对标摊偏差为5.89%:水果样品添加浓度0.020 mg/kg:对标准偏差为5.77%;添加浓度0.10 mg/kg相对标准偏差为5.00%,添加浓度0.50 g/kg,相对标准偏差为8.58%。10

附录A

(资料性附录)

标准物气相色谱-质谱图

t/imen

多效唑标准品气相色谱-质谱总离子流图(TIC)236

Il ior+ pall

20Y218

多效唑标准品质谱图

SN/T1477—2004

SN/T 1477—2004

Foreword

Annex A of this standard is an informative annex.This standard was proposed by and is under the charge of Certification and Accreditation Administration of P. R. c

This standard was drafted by China Academy of Inspection and Quarantine,This standard was mainly drafted by Bai Hua, Qiu Yusming, Hao Nan, Zhang Qing.This standard is a professional standard promulgated for the first tirneNote: This English version, a translation from the China text, is solely for guidance.1

Inspection of paclobutrazol

SN/T 1477—2004

residues in food for import and exportThis stancard specifies the methods of sampling, sample preparation and determination ofpaclobutrazol residues by Gc-Ms in food for import and export.This standard is applicable to the determination of pacfobutrazol residuas in cereals and fruits for im-port and export.

Sampling and Sample preparation2

2. 1 Cereal sample

2. 1. 1Inspection lot

Eachinspectionlotshouldnotexceed4000bags(200t).The characteristics of the cargo within the same inspection lot, such as packing, mark, origin, spaci-fication, grade etc. ,should be the sarne.2. 1. 2Quantity of sample takenThe number of bags to be sampled shall be catculated according to the formula (1) :aN

N--total number of bags in a lot;a-number of bags to be taken (if value a is with decimal,round off the decimal part, which isadded as unity to the integral part of a).2. 1. 3Sampling tools

Metallic sampler: Stainless steel tube, length (including handle): 55 cm; diameter:1, 5 cm:a)

groove length: longer than half the diagonal length of the bag;b)

2. 1. 4. 1

Sampling shovel;

Plate for quartering:

Sample can (bag). which can be sealed:Cloth (or other suitable material) sheet: For sample dividing(quartering),Sampling procedure

Sampling by emptying out: Draw 10 percent of the number of bags specified in 2. 1. 2 (not7

SN/T1477—2004

less than 3 bags ) at any part of the pile at random. Unseam and open the bag, and lay it on a cleancloth sheet(or other clean sheet), Grasp tight two corners of the bag bottom anid raise up to angle of45°, tug backward for ca 1 m until ail content of the bag is emptied out. Check whether the qualityof the goods is uniform within and between the bags. After confirming the goods are in normal con-dition, scoop up the sample from different parts of the out- poured content with a shovel, and placein a sample container promptiy. The quantity of the sample drawn fram each bag should be basicallythe same.

2. 1.4. 2Sampling from inside the bags: Draw the samples from 90 percent of the number of bagsspecified in 2. 1.2 as fallaws: Along the sine wave of the pile. draw samples from the bags af theupper, middle and lower parts of the pile at random. Insert the sampler, with its groove facingdawnward, diagonaly inta each bag. then turn the sampler by 180',draw out the sampler, promptlypour the sample into a container. The quantity of the sample drawn from each bag shall be basicallythe same as in 2. 1. 4. 1

The total weight of the representative sample of each lot should be not less thar 4 kg.2. 1.4.3Reductian of gross samplePour all the samples (from both 2. 1. 4. 1 and 2. 1. 4. 2) on a clean sheet, reduce to not less than 2 kgwith a plate by quartering. Piace in a sample container, seal, label and send to the laboratory in time.2. 1. 5 preparation of test sampleReduce the sample to ca 1 kg by quartering: grind thoroughly and let pass through a 20 mesh sieve,mix thoroughly and divide into 2 equal portions, place in clean containers as the test samples, sealand label.

2. 1.6 Storage of test sampleThe test sample shall be stored below -5 ℃ and kept away from light.2. 2Fruit sample

2.2.1Inspection lot

The quantity of an inspection lot should not be more than 1 5oo packages.The characteristics of the cargo within the same inspection lot, such as packing, mark, origin, gradeand specification, shonld be the same.2. 2. 2 Quantity of sample takenQuantity of sample taken see Table 1.Table 1

Number of packages in each inspection lot1~25

26~100

101~250

251~1500

Minimum number af packages to be taken5

2. 2. 3 Sampling procedure

SN/T 1477—2004

A number of packages specified in 2. 2. 2 are taken at random and opened one by one. The sampleweight taken as the primary sample from each package should be at least 50o grams, The totalweight of all primary samples should not be less than 2 kg. which should he sealed, labeled and sentto laboratory in time

2.2.4Preparation of test sampleThe combined primary sample is reduced to 1 kg: the adible portions are blended. and then dividedinto two equal portions. Each portion is placed in a clean container as the test sample, which is thensealed and labeled.

2.2.5Storage of test sample

The test samples shonld be stored below - 18℃.2.3Attention

In the course Of sampling and sample preparation. precaution should be taken to avoid contaminationor any factors which may cause the change of residue content3Method of determinatian

3, 1 Princinle

Paclobutrazol is extracted from sarnple with acetone or acetic acetate-acetone. After evaporation afsolvents, the residue is dissolved in n-hexane-acetone and then cleaned by Florisil column, The elu-tion is concentrated and the residue is redissolved in n-hexane, Paclobutrazol is determinated by GC-Ms and quantified from calibration curve.3,2Reagents and materials

Unless specifically mentioned, all reagents used should be analytical grade , \ water\ jsdeionized water.

Acetone: redistilled.

n-Hexane: redistilled.

Acetic acetate: redistilled.3.3.4

Acetic acetate -Acetone: 20 mL of acetone diluted to 100 ml with acetic acetate.3. 2. 5 Wash soluition (n-Hexane-Acetone): 5 mL of acetone diluted to 100 mL with n-hexane.3. 2. 6 Elution (n-Hexane-Acetone) : 15 mL of acetone diluted to 100 mL with n-hexane.9

SN/T1477—2004

3.2.7Paclobutrazol standard: Purity99 %.3. 2. 8Paclobutrazol standard solution; Certain amount of paclobutrazol weighed accurately(accu-rate to 0. 1 mg) and dissolved in n-hexane to prepare 100 μg/ mL standard stock solution, and dilutedto suitable concentration with n-hexane as standard working solution.3. 2. 9Anhydrous sodium sulfate: tgnited at 650'℃ for 4 h, and stored in desiccator3. 2. 10 Florisil: 60 ~100 mesh, chromatographic grade, heated at 140℃ for 4 h, and stored in desic.cator.

Apparatls and equipment

Gas Chramatograph-Mass Spectrometry.Rotary evaporator.

Conicalflask:25oml.withground-giassstopper.3.3.5

Pear-shaped flask: 250 mL.

Florisil column:250 mm×10mm glass calumn filead with 2 cm of anhydrous sodium、2 g of3.3.6

Florisil and 2 cm of anhydrous sodiuin.3.4 procedure

3.4.1Extraction

Cereals sample: 10 g (accurate to 1 rmg) of test sample is weighed in a 250 mL conical flask,30 ml. ofacetone is added arid shaked for 30 min. The extraction is repeated. Then filtered into a 250 mi.pear-shaped flask. The conical flask and filter cake are rinsed twice with 20 ml of acetone. Ali acetonesolutions are combined in the pear-shaped flask, evaporated to nearly dry in a water bathunder 40℃.

Fruits sampie: 10 g (accurate to 1 mg) of test sample is weighed in a 250 mL conical flask.50 mL ofacetic acetate-acetone(3.2.4) is added and shaked for1h.The extraction is repeated with 30mLofacetic acetate -acetone(3, 2. 4) and shaked for 30 min. Then filtered into a 250 ml pear-shaped flask.The conical flask and filter cake are rinsed twice with 20 mL of acetic acetate -acetone (3. 2. 4) : Alsoiutions are combined in the pear-shaped flask, evaporatect to nearly dry in a water bath under 40 3. 4. 2 Clean up

The above dried extraction is redissolved in 5 mL of n-hexane-acetcne (3. 2. 5) by a few times andtransferred to the Florisil colurmn (3. 3. 6). The column is washed with 40 mL of n-hexane-acetone0

SN/T1477—2004

(3. 2. 5), then eluted with 30 mL of n-hexane-acetone (3. 2. 6). The eluent is collected into pear-shaped flask and evaporated in a water bath under 4o'c , then dried with a gentle nitrogen stream.The residue is redissolved in 1 mL of n-hexane.3. 4. 3Determination

3, 4. 3. 1 Operating conditiansa)

Colurmn: HP-5 30 m × 0.25 mm (i. d. ) x 0. 25 μm (film thickness) or equiyalent.Coiurmntemperature:100℃-→20℃/min-220℃→+5℃/min-+250℃(15min).Injection temperatire: 28a'c.Source temperature: 230'c.

Interfacetemperature:280'c.

lon source: Et.

Derermination mode: selected iori rronitoring.Selected ions(m/2) : 125,167,236.Cartier gas: He, Purity ≥99. 999% . flow rate: 1.0 mL/min.Injection mode: Splitless. valva activated at 1 min.k) Injection volurne: 1 μL.3.4. 3.2GC-Ms determination

Inject accurately equal amount (1 μL)of the paciobutrazo! standard working soiution and sampling so.lution (3.4.2)into Gc-Ms respectiveiy,the responses of tha paciobutrazol in the standard workingsolution and sampie soiution should be similar and must be within the ltinear range ot the detector(0. 05 ng -~5, 0 ng). Sample solutions should be injected in betwsen standard solutions. The retention time of pactobutrazol is about t0. 7 min under the above conditions (3. 4, 3. 1). Gc-Ms Chromat-ogram of paclobutrazoi standard is Fig. A, 1.3. 4. 3. 3 GC-MS tonfirmationA peak couid be identifiad as paclobutrazel if it is in accordance with the following coridition:The peak has a retention time of about 1o, 7 min, the selected ions monitored could be found in themass spectrum of the peak, and the relative abundance of the segments of the sample peak is com-patible to those of the standard peak. Mass specirum of paclobutrazol standare is Fig.A.2.3. 4. 4Blank test

The operation of blank test is the same as above, except without sample.3. 5Calculatian and expresssion of resultThe content of paclobutrazal is caiculated by the following formnula (2) :X=

X-the residue content of paclobutrazol in test sample. mg/kg;A-- -peak area (or peak height ) of paclobutrazof in sample solution:(2)

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

标准图片预览:

- 热门标准

- 商检行业标准(SN)

- SN/T1509-2005 异尖线虫病诊断规程

- SN/T1672.7-2013 进出口医用设备检验规程 第7部分:医用内窥镜

- SN/T0328-94 出口氟石中氟化钙的化学分析方法

- SN/T1083.1-2002 焦炭分析试样水分、灰分的快速测定

- SN/T1359.2-2004 进口纺织机械检验规程 织袜机

- SN/T1395.2-2005 禽衣原体病琼脂免疫扩散试验操作规程

- SN/T4381-2015 食品接触材料纸、再生纤维材料使用改性聚苯醚测定纸和纸板迁移物的试验方法

- SN/T1443.2-2004 食品安全管理体系 审核指南

- SN0665-1997 出口肉及肉制品中雌三醇残留量检验方法放射免疫法

- SN/T0226.2-1993 出口冻公鱼检验规程

- SN/T0380-1995 出口活鱼检验规程

- SN/T0794-1999 进出口西洋参检验规程

- SN/T0801.6-1999 进出口动植物油脂沉积物检验方法

- SN/T1891.6-2007 进出口微波食品包装容器及包装材料卫生标准 第6部分:玻璃制品

- SN/T2552.1-2010 乳及乳制品卫生微生物学检验方法 第1部分:取样指南

- 行业新闻

请牢记:“bzxz.net”即是“标准下载”四个汉字汉语拼音首字母与国际顶级域名“.net”的组合。 ©2025 标准下载网 www.bzxz.net 本站邮件:bzxznet@163.com

网站备案号:湘ICP备2025141790号-2

网站备案号:湘ICP备2025141790号-2