- 您的位置:

- 标准下载网 >>

- 标准分类 >>

- 商检行业标准(SN) >>

- SN/T 2223-2008 进出口动物源性食品中硫粘菌素残留量检测方法 液相色谱-质谱/质谱法

【商检行业标准(SN)】 进出口动物源性食品中硫粘菌素残留量检测方法 液相色谱-质谱/质谱法

本网站 发布时间:

2024-06-28 03:36:27

- SN/T2223-2008

- 现行

- 点击下载此标准

标准号:

SN/T 2223-2008

标准名称:

进出口动物源性食品中硫粘菌素残留量检测方法 液相色谱-质谱/质谱法

标准类别:

商检行业标准(SN)

标准状态:

现行-

发布日期:

2008-11-18 -

实施日期:

2009-06-01 出版语种:

简体中文下载格式:

.rar.pdf下载大小:

1,021.06 KB

点击下载

标准简介:

标准下载解压密码:www.bzxz.net

SN/T 2223-2008 进出口动物源性食品中硫粘菌素残留量检测方法 液相色谱-质谱/质谱法 SN/T2223-2008

部分标准内容:

中华人民共和国出入境检验检疫行业标准SN/T2223—2008

进出口动物源性食品中硫粘菌素残留量检测方法

液相色谱-质谱/质谱法

Determination of tiamulin residue in foodstuffs of animal originfor import and export-LC-MS/MS method2008-11-18发布

中华人民共和国

国家质量监督检验检疫总局

2009-06-01实施

本标准的附录A和附录B均为资料性附录。本标准由国家认证认可监督管理委员会提出并归口SN/T2223—2008

本标准起草单位:中华人民共和国辽宁出入境检验检疫局、中华人民共和国江西出人境检验检疫局、大连工业大学。

本标准主要起草人:孙兴权、林维宣、温志海、张玉苍本标准系首次发布的出入境检验检疫行业标准I

http://foodmate.net1范围

进出口动物源性食品中硫粘菌素残留量检测方法

液相色谱-质谱/质谱法

SN/T2223—2008bZxz.net

本标准规定了进出口动物组织中硫粘菌素残留量的液相色谱-质谱/质谱测定方法。本标准适用于猪肉、猪肝、猪肾中硫粘菌素残留量的检测和确证。2规范性引用文件

下列文件中的条款通过本标准的引用而成为本标准的条款。凡是注日期的引用文件,其随后所有的修改单(不包括勘误的内容)或修订版均不适用于本标准,然而,鼓励根据本标准达成协议的各方研究是否可使用这些文件的最新版本。凡是不注日期的引用文件,其最新版本适用于本标准。GB/T6682分析实验室用水规格和试验方法。(GB/T6682一2008,ISO3696:1987,MOD)3方法提要

试样经乙酸乙酯提取,正已烷脱脂,固相萃取小柱净化后,液相色谱-质谱/质谱法测定和确证,外标法定量。

4试剂和材料

除另有说明外,所用试剂均为分析纯,水为GB/T6682规定的一级水。4.1乙酸乙酯:色谱纯。

4.2正已烷:色谱纯。

4.3甲醇:色谱纯。

4.4乙睛:色谱纯。

4.5乙酸铵。

4.60.1%乙酸铵:称取1.0g乙酸铵,加水溶解并定容至1000mL。4.7硫粘菌素标准物质(Tiamulin):C28HaNO,S.CASNo.55297-95-5,纯度大于等于98.8%。4.8硫粘菌素标准储备溶液(1.0mg/mL):称取适量的硫粘菌素标准物质(4.7),用甲醇配成1.0mg/ml的标准储备液。储备液置于一18℃避光贮存。4.9硫粘菌素标准工作溶液(1.0μg/mL):吸取适量的硫粘菌素标准储备溶液(4.8).用甲醇配成1.0ug/mL的标准工作溶液。标准工作溶液置于4℃避光贮存。4.10固相萃取小柱:WatersoasisHLB柱,500mg,6mL,或相当者。4.11微孔滤膜:0.45μm,有机相。5仪器和设备

5.1液相色谱-串联四极杆质谱仪:配有电喷雾离子源。5.2分析天平:感量分别为0.1mg和0.01g。5.3绞肉机。

5.4涡旋混合器:2000r/min

SN/T2223—2008

5.5离心机:3000r/min。

5.6旋转蒸发器。

5.7固相萃取装置。

5.8具塞离心管:聚四氟乙烯,15mL和50mL6试样制备与保存

从所取动物肌肉、肝脏、肾脏全部样品组织中取出有代表性样品约0.5kg,用绞肉机充分绞碎混匀均分成两份。制备好的试样置于样品瓶中,密封,并标明标记,于一18℃以下冷冻存放。试样制备与保存过程中应防止样品受到污染或发生残留物含量的变化7测定步骤

7.1提取

称取5g试样(精确到0.01g)于50mL离心管(5.8)中加入25mL乙酸乙酯(4.1)2000r/min涡旋混匀2min,3000r/min离心5min.收集提取液至浓缩瓶中。残渣再加人20mL乙酸乙,重复上述抽提操作。合并提取液,50℃以下旋转浓缩至近干。用4mL正已烷(4.2)和4mL水依次将残渣转移至15mL离心管(5.8)中,2000r/min涡旋混匀1min,3000r/min离心3min.弃去上层正已烷溶液,再加人4mL正已烷,重复上述脱脂操作,所得水层提取液待净化。7.2净化

分别用甲醇(4.3)和水各3mL对OasisHLB固相萃取小柱(4.10)进行活化预处理,然后将测定步骤7.1所得水层提取液转移至小柱上,控制流出速度小于2mL/min。用10mL水分次洗涤离心管,洗涤液淋洗OasisHLB小柱后弃去。用6mL甲醇洗脱,收集全部洗脱液,加水定容至10mL,混匀后过0.45um滤膜(4.11),供液相色谱-串联质谱测定。7.3硫粘菌素基质校准标准溶液的配制称取七个基质空白样品(称样量为5g)于50mL离心管(5.8)中,其中六个空白样品中分别加人适量硫粘菌素标准工作溶液(4.9),按照样品操作步骤7.1、7.2同步操作,使最终样品溶液中硫粘菌素的浓度分别为2.5ng/mL.5.0ng/mL、10ng/mL、20ng/mL、50ng/mL、100ng/mL。所得系列硫粘菌素基质标准校准溶液即配即用,用以制作标准曲线。7.4测定

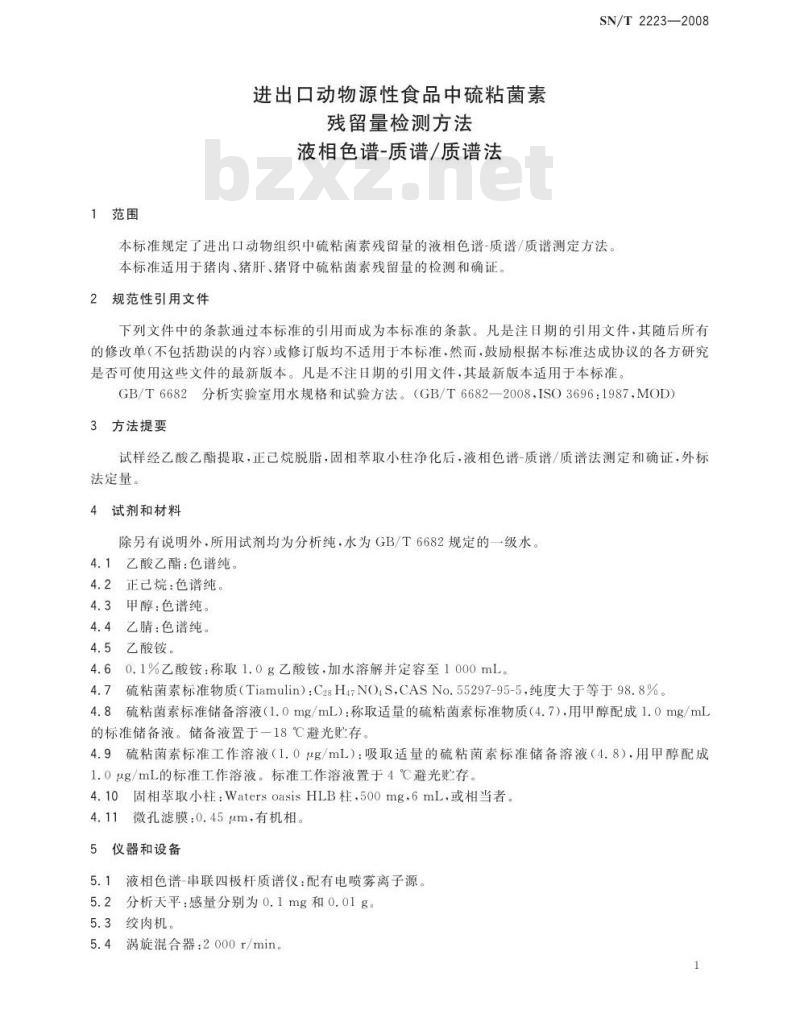

7.4.1液相色谱条件

色谱柱:ZORBAXEclipseXDB-C18,150mmX2.1mm(内径),5μm,或相当者;a)

b)进样量:5.0μL;

流速:0.3mL/min;

流动相组成及梯度洗脱程序见表1。d)

表1液相色谱梯度洗脱程序

时间/min

7.4.2质谱条件

离子源:电喷雾离子源;

甲醇/%

0.1%乙酸铵/%

乙睛/%

b)扫描方式:正离子扫描;

c)检测方式:多反应监测;

SN/T2223—2008

d)雾化气、气帘气、辅助气、碰撞气均为高纯氮气;使用前应调节各参数使质谱灵敏度达到检测要求,质谱条件参见附录A。

7.4.3液相色谱-质谱/质谱测定

7.4.3.1定性测定

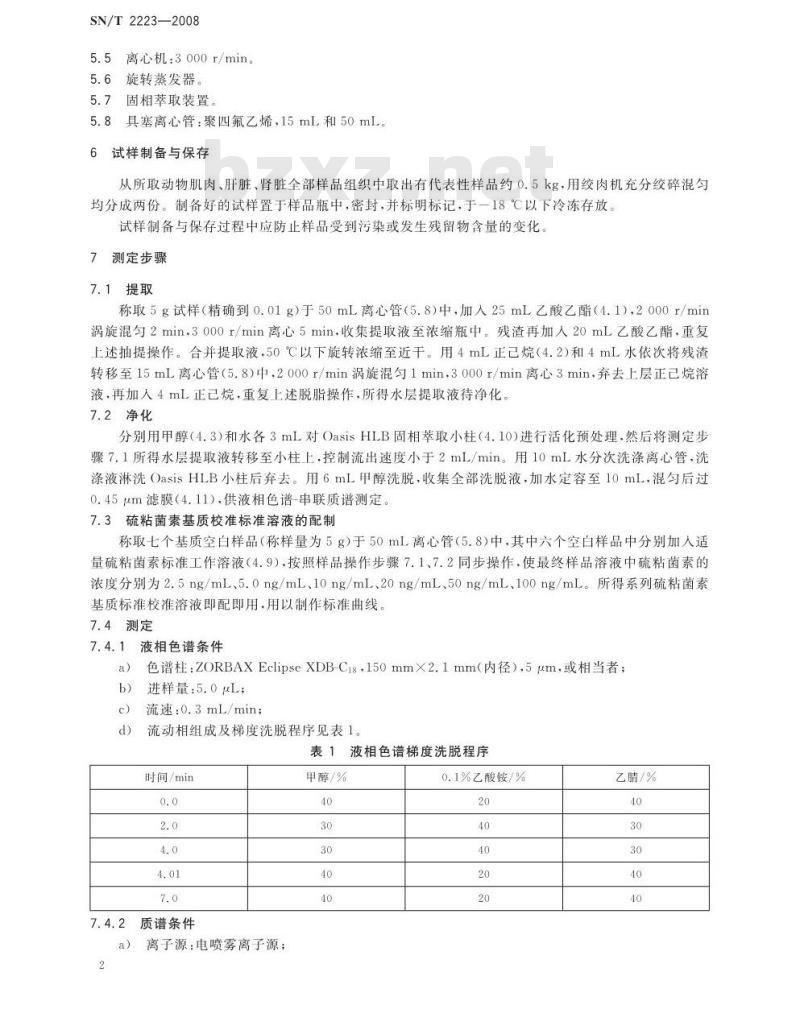

在相同试验条件下,样品中待测物质与同时检测的浓度相近的基质校准标准溶液具有相同的保留时间,并且所选择的离子相对丰度比相一致或在表2规定的充许偏差范围内,则可判断样品中存在对应的被测物。在上述实验条件下,硫粘菌素的保留时间约为2.74min,定性离子对(m/z)为494.2/191.9;494.2/163.4:494.2/118.8.定量离子对为494.2/191.9,参考离子相对丰度比(%)分别为100.00;32.92;28.31,相应的谱图参见附录B。表2定性确证时离子相对丰度比的最大允许偏差相对离子丰度比/%

允许的相对偏差/%

7.4.3.2定量测定

>20~50

>10~20

在仪器最佳工作条件下,对硫粘菌素的基质校准标准溶液分别进样,以峰面积为纵坐标,系列基质校准标准溶液浓度为横坐标绘制标准工作曲线,用标准工作曲线对样品进行定量,样品溶液中待测物的响应值均应在仪器测定的线性范围内。7.5空白试验

除不加试样外,均按上述步骤操作。8结果计算

按式(1)计算试样中硫粘菌素残留量:X=(c-co).V

式中:

试样中硫粘菌素残留量,单位为微克每于克(ug/kg):从标准曲线中得到的被测组分溶液浓度,单位为纳克每毫升(ng/mL):从标准曲线中得到的空白试验中被测组分的溶液浓度,单位为纳克每毫升(ng/mL);样品溶液最终定容体积,单位为毫升(mL);最终样液所代表试样质量,单位为克(g)。9测定低限和回收率

9.1测定低限

本方法的测定低限为10ug/kg。

9.2回收率

不同样品基质,不同添加浓度下的硫粘菌素回收率范围数据见表3。表3不同基质中不同硫粘菌素添加水平的回收率范围基质

添加水平/(ug/kg)

回收率/%

76.3~87.8

82.5~96.5

SN/T2223—2008

表3(续)

添加水平/(μug/kg)

http://foodmate.net回收率/%

78.3~85.7

86.3~94.8

83.5~92.5

质谱条件:

化合物

电喷雾电压(IS):4500V;

附录A

(资料性附录)

质谱条件1)

雾化气压力(GS1):137.9kPa(20psi);气帘气压力(CUR):130.425kPa(15psi);碰撞气压力(CAD):75.845kPa(11psi);辅助气流速(GS2):35L/min;离子源温度(TEM):600℃;

Q1、Q3均为单位分辨率(Unit);SN/T2223—2008

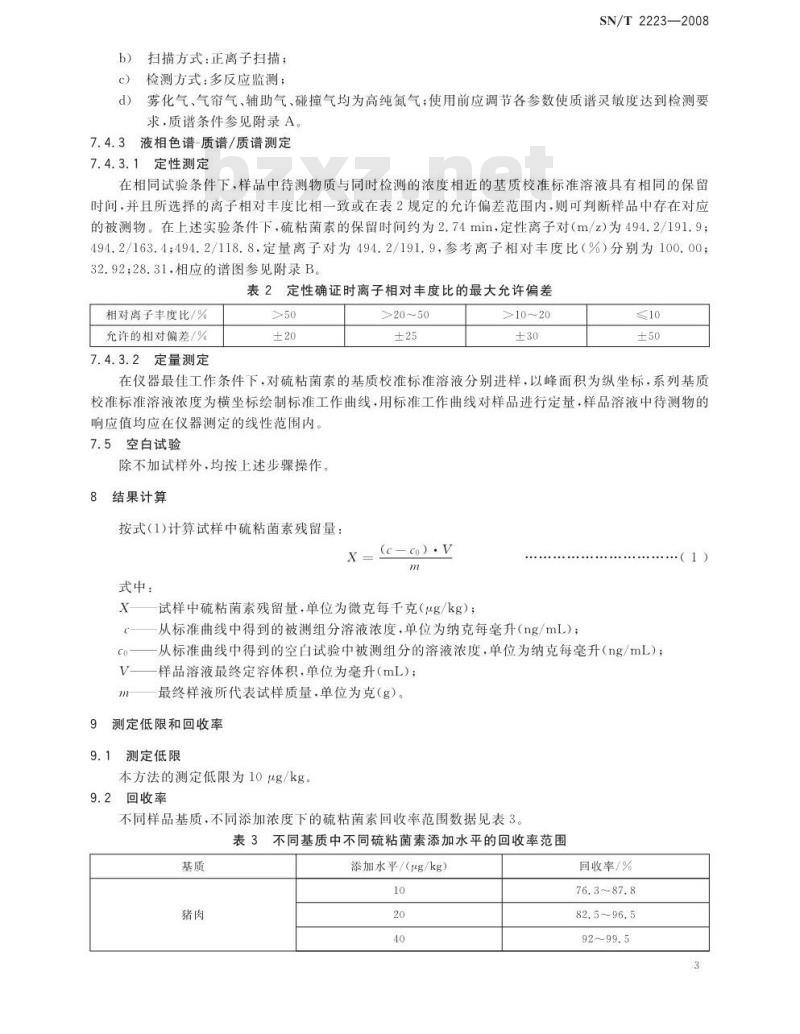

硫粘菌素的定性离子对、定量离子对、采集时间、去簇电压(DP)、入口电压(EP)、碰撞能量(CE)及碰撞室出口电压(CXP)等参数见表A.1。表A.1

定性离子对

494.2/191.9

硫粘菌素

494.2/1634

494.2/118.8

定量离子对

494.2/191.9

硫粘菌素的主要质谱参考条件参数采集时间

去簇电压

(DP)/V

人口电压

(EP)/V

碰撞能量

(CE)/V

碰撞室出口电

压(CXP)/V

1)附录A所列参数是在API4000质谱仪上完成的,此处列出实验用仪器型号仅供参考.不涉及商业目的,鼓励标准使用者尝试不同厂家和型号的仪器5

http://foodmate.netSN/T2223—2008

494.2/191.9

附录B

(资料性附录)

XIC和离子相对丰度比图谱

.a1o1G2.0

494.2/163.4

494. 2/118. 8

494.2/191.9

s4.a.5o5.56o6.5t/nin

49.2/16.1. 4

0,/0, masinamm

6.h.st/mir

494.2/118.B

硫粘菌素的提取离子流图(XIC)以及离子相对丰度比图谱图B.1

http://foodmate.netForeword

AnnexAandAnnexBofthisstandardareinformativeannexesSN/T2223—2008

This standard was proposed by and is under the charged of certification and accreditation administa-tionofthePeople'sRepublicof China.This standard was drafted by Liaoning Entry-Exit Inspection and Quarantine Bureau of the People'sRepublic of China,Jiangxi Entry-Exit Inspection and Quarantine Bureau of the People's RepublicofChina and Dalian Polytechnic University.ThestandardwasmainlydraftedbySunXing-quan,LinWei-xuan,WenZhi-hai,ZhangYu-cangThis standard is a professional standardfor entry-exit inspection andquarantinepromulgated forthefirsttime

SN/T2223—2008

Determinationoftiamulinresidueinfoodstuffsofanimal originforimportandexport-LC-MS/MS method

The standard specifiesthemethods fordetermination of tiamulinresidues inanimalfood byhighper.formanceliquidchromatographyandtandemmassspectrometryThe standard is applicable to the determination of tiamulin residues in muscle,liver andkidney of pigsamples.

2Reference

For the files with an indication of date,the sequencely modified versions (disincluding the contentsof errata) or revised versions of them would not be applicable to this standard. However,it is en-couraged for those have reached an agreement according to this standard to research whether to usethe latest version of these documents.For the files without an indication of date,their lastest ver-sionswouldbeapplicabletothis standardGB/T6682Specification and test method for water used inanalytical lab(GB/T6682-2008,ISO3696:1987,MOD)

Principle

Tiamulin residue is extracted from the sample with ethyl acetate.And the extract is defatted withn-hexane and cleaned up with hydrophiliclipophilic balance (HLB) solid phase extraction columnsequently.Finally the analyte is determinated by high performance liquid chromatography and tandemmassspectrometry,usingexternalstandardmethod.4

Reagentsandmaterials

Unless otherwise specified,all the reagent is analystic grade and \water\is deionized water.4.1 Ethyl acetated:HPLC grade4.2

n-Hexane:HPLCgrade

Methanol:HPLCgrade.

Acetonitril:HPLC grade

Ammoniumacetate(NH4Ac).

0.1% NH4Ac:Weigh 1.0 g NH4Ac and desolve in 1000 mLwater.Tiamulin(C2:H47NO4S):CASNo:55297-95-5.purity≥98.8%SN/T2223—2008

Stock solution oftiamulin:1.omg/mL.Weighcertainamount of the standard accurately.and4.8

dissolve it withmethanol to preparea stock solution whichconcentrationis1.O mg/mL.The solutioncould be available if it is stored at -18 ℃ in refrigerator avoiding light.4.9Working solution of tiamulin:1.0 μg/mL.Certain amount of tiamulin stock solutionof tiamulinwas diluted with methanol into a kind of tiamulinworking solution which concentration is1.O μg/mL. The solution could be available if it is stored at 4 C in refrigerator avoiding light.4.10

HLBSPEcolumn:500mg6mLorequivalentFilm:0.45μm.Organicphase.

Apparatusandequipment

Liquidchromatographywithelectrosprayionizationmassspectrometry5.2

Balancewhosesensitivityshouldbe0.1mgor0.01g5.3

MeatMixer.

Vortex mixer.

Centrifuge:3000 r/min.

Rotaryvacuumevaporator.

Apparatusfor solid phaseextraction.5.8Centrifugetubewithcap:15mLand50mLPreparation and storage of test sample6

Take a representative portion whose weight is about 0.5 kg from the whole primary sample such asmusculature,liver and kidney and ground it in a blender. Depart and keep the prepared sample into9

SN/T2223—2008

two sample bottles equally before seal and label,then stored them in-18℃ refrigerator.It isimportant for the detecting analyte to avoiding pollution and keep its concentration without variedduringthewholestoring period7

Procedure

7.1Extraction

Weigh 5g of the test sample(accurate to 0.01g)into a 50 mL centrifuge tube.Add25mL ethyl ace-tate into the tube and homogenize for 2 min at 2 000 r/min. Centrifuge the mixture at 3 000 r/min for5min,and thesupernatant layer was displaced intoa bottlefor rotary evaporation.Repeat the extractingprocedurewith20mL ethylacetateand combined theextracted solution.Thenreducedpressureevaporate the solution tonearlydryness in a water bath blow50 ℃.Add 4 mL n-hexane and 4 mLwater to dissolve residues and transferthem into a 15 mL centrifuge tube sequencely.Blend themix-turefor1min under 2000 r/min,centrifuge for3 minunder2000 r/min,and discard the supernatantlayer.Add4mLn-hexanetorepeatthedefattingprocedure7.2Cleanup

Transfertheanalyte solution in water layer into theHLBSPE column whichhasbeenprocessed with3mLmethanol followed by3mLwater sequencely,and makingtheflowratebelow2mL/min inthecontrol.Rinse the SPE column with 10 mL water,then discard the eluate. Collect all the eluted solu-tion after elute the column with 6 mL methanol and adjust the elutate volume to 10 mL with water.Mixthe solutionand filterit through0.45μmfilm.Thefiltrate is readyforLC-MS/MSdetermination.7.3PreparationofTiamulinstandardsolutioncalibratedbyMatrixWeigh seven negative matrix samples whose weight is 5g respectively into 50 mL centrifuge tube,and spike a certain amount of tiamulin working solution into six of them. Then process these samplesaccording to the analytic steps 7.1 and 7.2 as the procedure mensioned above to prepare the stand-ardsolutionswhichconcentrationare2.5ng/mL,5.0ng/mL,10ng/mL,20ng/mL,50ng/mL,100ng/mL respectively.The Tiamulin standard solutions calibrated byMatrix aremadeforobtainingastandard curveand shouldbeusedafterpreparedtimely7.4Determination

7.4.1HPLCoperatingconditionsColumn:ZORBAX Eclipse XDB-C18,150 mm×2.1mm(i.d.),5 μm,or the equivalent;a)

Injection volume:5.0μL;

Flow rate:0.3mL/min;

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

进出口动物源性食品中硫粘菌素残留量检测方法

液相色谱-质谱/质谱法

Determination of tiamulin residue in foodstuffs of animal originfor import and export-LC-MS/MS method2008-11-18发布

中华人民共和国

国家质量监督检验检疫总局

2009-06-01实施

本标准的附录A和附录B均为资料性附录。本标准由国家认证认可监督管理委员会提出并归口SN/T2223—2008

本标准起草单位:中华人民共和国辽宁出入境检验检疫局、中华人民共和国江西出人境检验检疫局、大连工业大学。

本标准主要起草人:孙兴权、林维宣、温志海、张玉苍本标准系首次发布的出入境检验检疫行业标准I

http://foodmate.net1范围

进出口动物源性食品中硫粘菌素残留量检测方法

液相色谱-质谱/质谱法

SN/T2223—2008bZxz.net

本标准规定了进出口动物组织中硫粘菌素残留量的液相色谱-质谱/质谱测定方法。本标准适用于猪肉、猪肝、猪肾中硫粘菌素残留量的检测和确证。2规范性引用文件

下列文件中的条款通过本标准的引用而成为本标准的条款。凡是注日期的引用文件,其随后所有的修改单(不包括勘误的内容)或修订版均不适用于本标准,然而,鼓励根据本标准达成协议的各方研究是否可使用这些文件的最新版本。凡是不注日期的引用文件,其最新版本适用于本标准。GB/T6682分析实验室用水规格和试验方法。(GB/T6682一2008,ISO3696:1987,MOD)3方法提要

试样经乙酸乙酯提取,正已烷脱脂,固相萃取小柱净化后,液相色谱-质谱/质谱法测定和确证,外标法定量。

4试剂和材料

除另有说明外,所用试剂均为分析纯,水为GB/T6682规定的一级水。4.1乙酸乙酯:色谱纯。

4.2正已烷:色谱纯。

4.3甲醇:色谱纯。

4.4乙睛:色谱纯。

4.5乙酸铵。

4.60.1%乙酸铵:称取1.0g乙酸铵,加水溶解并定容至1000mL。4.7硫粘菌素标准物质(Tiamulin):C28HaNO,S.CASNo.55297-95-5,纯度大于等于98.8%。4.8硫粘菌素标准储备溶液(1.0mg/mL):称取适量的硫粘菌素标准物质(4.7),用甲醇配成1.0mg/ml的标准储备液。储备液置于一18℃避光贮存。4.9硫粘菌素标准工作溶液(1.0μg/mL):吸取适量的硫粘菌素标准储备溶液(4.8).用甲醇配成1.0ug/mL的标准工作溶液。标准工作溶液置于4℃避光贮存。4.10固相萃取小柱:WatersoasisHLB柱,500mg,6mL,或相当者。4.11微孔滤膜:0.45μm,有机相。5仪器和设备

5.1液相色谱-串联四极杆质谱仪:配有电喷雾离子源。5.2分析天平:感量分别为0.1mg和0.01g。5.3绞肉机。

5.4涡旋混合器:2000r/min

SN/T2223—2008

5.5离心机:3000r/min。

5.6旋转蒸发器。

5.7固相萃取装置。

5.8具塞离心管:聚四氟乙烯,15mL和50mL6试样制备与保存

从所取动物肌肉、肝脏、肾脏全部样品组织中取出有代表性样品约0.5kg,用绞肉机充分绞碎混匀均分成两份。制备好的试样置于样品瓶中,密封,并标明标记,于一18℃以下冷冻存放。试样制备与保存过程中应防止样品受到污染或发生残留物含量的变化7测定步骤

7.1提取

称取5g试样(精确到0.01g)于50mL离心管(5.8)中加入25mL乙酸乙酯(4.1)2000r/min涡旋混匀2min,3000r/min离心5min.收集提取液至浓缩瓶中。残渣再加人20mL乙酸乙,重复上述抽提操作。合并提取液,50℃以下旋转浓缩至近干。用4mL正已烷(4.2)和4mL水依次将残渣转移至15mL离心管(5.8)中,2000r/min涡旋混匀1min,3000r/min离心3min.弃去上层正已烷溶液,再加人4mL正已烷,重复上述脱脂操作,所得水层提取液待净化。7.2净化

分别用甲醇(4.3)和水各3mL对OasisHLB固相萃取小柱(4.10)进行活化预处理,然后将测定步骤7.1所得水层提取液转移至小柱上,控制流出速度小于2mL/min。用10mL水分次洗涤离心管,洗涤液淋洗OasisHLB小柱后弃去。用6mL甲醇洗脱,收集全部洗脱液,加水定容至10mL,混匀后过0.45um滤膜(4.11),供液相色谱-串联质谱测定。7.3硫粘菌素基质校准标准溶液的配制称取七个基质空白样品(称样量为5g)于50mL离心管(5.8)中,其中六个空白样品中分别加人适量硫粘菌素标准工作溶液(4.9),按照样品操作步骤7.1、7.2同步操作,使最终样品溶液中硫粘菌素的浓度分别为2.5ng/mL.5.0ng/mL、10ng/mL、20ng/mL、50ng/mL、100ng/mL。所得系列硫粘菌素基质标准校准溶液即配即用,用以制作标准曲线。7.4测定

7.4.1液相色谱条件

色谱柱:ZORBAXEclipseXDB-C18,150mmX2.1mm(内径),5μm,或相当者;a)

b)进样量:5.0μL;

流速:0.3mL/min;

流动相组成及梯度洗脱程序见表1。d)

表1液相色谱梯度洗脱程序

时间/min

7.4.2质谱条件

离子源:电喷雾离子源;

甲醇/%

0.1%乙酸铵/%

乙睛/%

b)扫描方式:正离子扫描;

c)检测方式:多反应监测;

SN/T2223—2008

d)雾化气、气帘气、辅助气、碰撞气均为高纯氮气;使用前应调节各参数使质谱灵敏度达到检测要求,质谱条件参见附录A。

7.4.3液相色谱-质谱/质谱测定

7.4.3.1定性测定

在相同试验条件下,样品中待测物质与同时检测的浓度相近的基质校准标准溶液具有相同的保留时间,并且所选择的离子相对丰度比相一致或在表2规定的充许偏差范围内,则可判断样品中存在对应的被测物。在上述实验条件下,硫粘菌素的保留时间约为2.74min,定性离子对(m/z)为494.2/191.9;494.2/163.4:494.2/118.8.定量离子对为494.2/191.9,参考离子相对丰度比(%)分别为100.00;32.92;28.31,相应的谱图参见附录B。表2定性确证时离子相对丰度比的最大允许偏差相对离子丰度比/%

允许的相对偏差/%

7.4.3.2定量测定

>20~50

>10~20

在仪器最佳工作条件下,对硫粘菌素的基质校准标准溶液分别进样,以峰面积为纵坐标,系列基质校准标准溶液浓度为横坐标绘制标准工作曲线,用标准工作曲线对样品进行定量,样品溶液中待测物的响应值均应在仪器测定的线性范围内。7.5空白试验

除不加试样外,均按上述步骤操作。8结果计算

按式(1)计算试样中硫粘菌素残留量:X=(c-co).V

式中:

试样中硫粘菌素残留量,单位为微克每于克(ug/kg):从标准曲线中得到的被测组分溶液浓度,单位为纳克每毫升(ng/mL):从标准曲线中得到的空白试验中被测组分的溶液浓度,单位为纳克每毫升(ng/mL);样品溶液最终定容体积,单位为毫升(mL);最终样液所代表试样质量,单位为克(g)。9测定低限和回收率

9.1测定低限

本方法的测定低限为10ug/kg。

9.2回收率

不同样品基质,不同添加浓度下的硫粘菌素回收率范围数据见表3。表3不同基质中不同硫粘菌素添加水平的回收率范围基质

添加水平/(ug/kg)

回收率/%

76.3~87.8

82.5~96.5

SN/T2223—2008

表3(续)

添加水平/(μug/kg)

http://foodmate.net回收率/%

78.3~85.7

86.3~94.8

83.5~92.5

质谱条件:

化合物

电喷雾电压(IS):4500V;

附录A

(资料性附录)

质谱条件1)

雾化气压力(GS1):137.9kPa(20psi);气帘气压力(CUR):130.425kPa(15psi);碰撞气压力(CAD):75.845kPa(11psi);辅助气流速(GS2):35L/min;离子源温度(TEM):600℃;

Q1、Q3均为单位分辨率(Unit);SN/T2223—2008

硫粘菌素的定性离子对、定量离子对、采集时间、去簇电压(DP)、入口电压(EP)、碰撞能量(CE)及碰撞室出口电压(CXP)等参数见表A.1。表A.1

定性离子对

494.2/191.9

硫粘菌素

494.2/1634

494.2/118.8

定量离子对

494.2/191.9

硫粘菌素的主要质谱参考条件参数采集时间

去簇电压

(DP)/V

人口电压

(EP)/V

碰撞能量

(CE)/V

碰撞室出口电

压(CXP)/V

1)附录A所列参数是在API4000质谱仪上完成的,此处列出实验用仪器型号仅供参考.不涉及商业目的,鼓励标准使用者尝试不同厂家和型号的仪器5

http://foodmate.netSN/T2223—2008

494.2/191.9

附录B

(资料性附录)

XIC和离子相对丰度比图谱

.a1o1G2.0

494.2/163.4

494. 2/118. 8

494.2/191.9

s4.a.5o5.56o6.5t/nin

49.2/16.1. 4

0,/0, masinamm

6.h.st/mir

494.2/118.B

硫粘菌素的提取离子流图(XIC)以及离子相对丰度比图谱图B.1

http://foodmate.netForeword

AnnexAandAnnexBofthisstandardareinformativeannexesSN/T2223—2008

This standard was proposed by and is under the charged of certification and accreditation administa-tionofthePeople'sRepublicof China.This standard was drafted by Liaoning Entry-Exit Inspection and Quarantine Bureau of the People'sRepublic of China,Jiangxi Entry-Exit Inspection and Quarantine Bureau of the People's RepublicofChina and Dalian Polytechnic University.ThestandardwasmainlydraftedbySunXing-quan,LinWei-xuan,WenZhi-hai,ZhangYu-cangThis standard is a professional standardfor entry-exit inspection andquarantinepromulgated forthefirsttime

SN/T2223—2008

Determinationoftiamulinresidueinfoodstuffsofanimal originforimportandexport-LC-MS/MS method

The standard specifiesthemethods fordetermination of tiamulinresidues inanimalfood byhighper.formanceliquidchromatographyandtandemmassspectrometryThe standard is applicable to the determination of tiamulin residues in muscle,liver andkidney of pigsamples.

2Reference

For the files with an indication of date,the sequencely modified versions (disincluding the contentsof errata) or revised versions of them would not be applicable to this standard. However,it is en-couraged for those have reached an agreement according to this standard to research whether to usethe latest version of these documents.For the files without an indication of date,their lastest ver-sionswouldbeapplicabletothis standardGB/T6682Specification and test method for water used inanalytical lab(GB/T6682-2008,ISO3696:1987,MOD)

Principle

Tiamulin residue is extracted from the sample with ethyl acetate.And the extract is defatted withn-hexane and cleaned up with hydrophiliclipophilic balance (HLB) solid phase extraction columnsequently.Finally the analyte is determinated by high performance liquid chromatography and tandemmassspectrometry,usingexternalstandardmethod.4

Reagentsandmaterials

Unless otherwise specified,all the reagent is analystic grade and \water\is deionized water.4.1 Ethyl acetated:HPLC grade4.2

n-Hexane:HPLCgrade

Methanol:HPLCgrade.

Acetonitril:HPLC grade

Ammoniumacetate(NH4Ac).

0.1% NH4Ac:Weigh 1.0 g NH4Ac and desolve in 1000 mLwater.Tiamulin(C2:H47NO4S):CASNo:55297-95-5.purity≥98.8%SN/T2223—2008

Stock solution oftiamulin:1.omg/mL.Weighcertainamount of the standard accurately.and4.8

dissolve it withmethanol to preparea stock solution whichconcentrationis1.O mg/mL.The solutioncould be available if it is stored at -18 ℃ in refrigerator avoiding light.4.9Working solution of tiamulin:1.0 μg/mL.Certain amount of tiamulin stock solutionof tiamulinwas diluted with methanol into a kind of tiamulinworking solution which concentration is1.O μg/mL. The solution could be available if it is stored at 4 C in refrigerator avoiding light.4.10

HLBSPEcolumn:500mg6mLorequivalentFilm:0.45μm.Organicphase.

Apparatusandequipment

Liquidchromatographywithelectrosprayionizationmassspectrometry5.2

Balancewhosesensitivityshouldbe0.1mgor0.01g5.3

MeatMixer.

Vortex mixer.

Centrifuge:3000 r/min.

Rotaryvacuumevaporator.

Apparatusfor solid phaseextraction.5.8Centrifugetubewithcap:15mLand50mLPreparation and storage of test sample6

Take a representative portion whose weight is about 0.5 kg from the whole primary sample such asmusculature,liver and kidney and ground it in a blender. Depart and keep the prepared sample into9

SN/T2223—2008

two sample bottles equally before seal and label,then stored them in-18℃ refrigerator.It isimportant for the detecting analyte to avoiding pollution and keep its concentration without variedduringthewholestoring period7

Procedure

7.1Extraction

Weigh 5g of the test sample(accurate to 0.01g)into a 50 mL centrifuge tube.Add25mL ethyl ace-tate into the tube and homogenize for 2 min at 2 000 r/min. Centrifuge the mixture at 3 000 r/min for5min,and thesupernatant layer was displaced intoa bottlefor rotary evaporation.Repeat the extractingprocedurewith20mL ethylacetateand combined theextracted solution.Thenreducedpressureevaporate the solution tonearlydryness in a water bath blow50 ℃.Add 4 mL n-hexane and 4 mLwater to dissolve residues and transferthem into a 15 mL centrifuge tube sequencely.Blend themix-turefor1min under 2000 r/min,centrifuge for3 minunder2000 r/min,and discard the supernatantlayer.Add4mLn-hexanetorepeatthedefattingprocedure7.2Cleanup

Transfertheanalyte solution in water layer into theHLBSPE column whichhasbeenprocessed with3mLmethanol followed by3mLwater sequencely,and makingtheflowratebelow2mL/min inthecontrol.Rinse the SPE column with 10 mL water,then discard the eluate. Collect all the eluted solu-tion after elute the column with 6 mL methanol and adjust the elutate volume to 10 mL with water.Mixthe solutionand filterit through0.45μmfilm.Thefiltrate is readyforLC-MS/MSdetermination.7.3PreparationofTiamulinstandardsolutioncalibratedbyMatrixWeigh seven negative matrix samples whose weight is 5g respectively into 50 mL centrifuge tube,and spike a certain amount of tiamulin working solution into six of them. Then process these samplesaccording to the analytic steps 7.1 and 7.2 as the procedure mensioned above to prepare the stand-ardsolutionswhichconcentrationare2.5ng/mL,5.0ng/mL,10ng/mL,20ng/mL,50ng/mL,100ng/mL respectively.The Tiamulin standard solutions calibrated byMatrix aremadeforobtainingastandard curveand shouldbeusedafterpreparedtimely7.4Determination

7.4.1HPLCoperatingconditionsColumn:ZORBAX Eclipse XDB-C18,150 mm×2.1mm(i.d.),5 μm,or the equivalent;a)

Injection volume:5.0μL;

Flow rate:0.3mL/min;

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

标准图片预览:

- 热门标准

- 商检行业标准(SN)

- SN/T2051-2008 食品、化妆品和饲料中牛羊猪源性成分检测方法实时PCR法

- SN/T3203-2012 进出口危险化学品检验规程爆炸品基本要求

- SN/T4341-2015 黑颜果实蝇检疫鉴定方法

- SN/T4115-2015 天然气中硫化物的分析方法气相色谱硫化学发光检测器法

- SN/T0239-93 出口钳形表检验规程

- SN/T3656.2-2013 进出口危险化学品测试技术规范第2部分:气体

- SN/T5138-2019 棉花黄萎病菌检疫鉴定方法

- SN/T0801.6-1999 进出口动植物油脂沉积物检验方法

- SN/T2389.10-2012 进出口商品容器计重规程第10部分:液体化工品船舱静态计重

- SN/T3676-2013 甘蔗凋萎病菌检疫鉴定方法

- SN0158-92 出口水果中螨完锡残留量检验方法

- SN/T4877.7-2017 基因条形码筛查方法 第7部分:检疫性轮枝菌

- SN/T3591-2013 实验室标准物质管理指南

- SN/T2925-2011 软体家具耐点燃性试验方法及评价

- SN/T2866-2011 爬行动物检验检疫监管规程

- 行业新闻

请牢记:“bzxz.net”即是“标准下载”四个汉字汉语拼音首字母与国际顶级域名“.net”的组合。 ©2025 标准下载网 www.bzxz.net 本站邮件:bzxznet@163.com

网站备案号:湘ICP备2025141790号-2

网站备案号:湘ICP备2025141790号-2