- 您的位置:

- 标准下载网 >>

- 标准分类 >>

- 商检行业标准(SN) >>

- SN/T 1511.1-2005 进出口果汁中乳酸含量检验方法

【商检行业标准(SN)】 进出口果汁中乳酸含量检验方法

本网站 发布时间:

2024-06-24 21:35:23

- SN/T1511.1-2005

- 现行

标准号:

SN/T 1511.1-2005

标准名称:

进出口果汁中乳酸含量检验方法

标准类别:

商检行业标准(SN)

标准状态:

现行-

发布日期:

2005-02-17 -

实施日期:

2005-07-01 出版语种:

简体中文下载格式:

.rar.pdf下载大小:

475.10 KB

部分标准内容:

中华人民共和国出入境检验检疫行业标准SN/T1511.1—2005

进出口果汁中乳酸含量检验方法Inspection of lactic acid in fruit juice for import and export2005-02-17发布

中华人民共和国

国家质量监督检验检疫总局

2005-07-01实施

本标准的附录A为资料性附录。

本标准由国家认证认可监督管理委员会提出并归口。本标准起草单位:中华人民共和国海南出人境检验检疫局。本标准主要起草人:张薇君、黄惠玲、陶文庆、贾泽梅、林道颖。本标准系首次发布的出入境检验检疫行业标准。SN/T1511.1—2005

1范围

进出口果汁中乳酸含量检验方法本标准规定了果汁中乳酸含量的抽样、制样和气相色谱测定方法。本标准适用于浓缩菠萝汁、苹果汁、葡萄汁、柑橘汁、芒果汁中乳酸含量的检验。2抽样和制样

2.1检验批

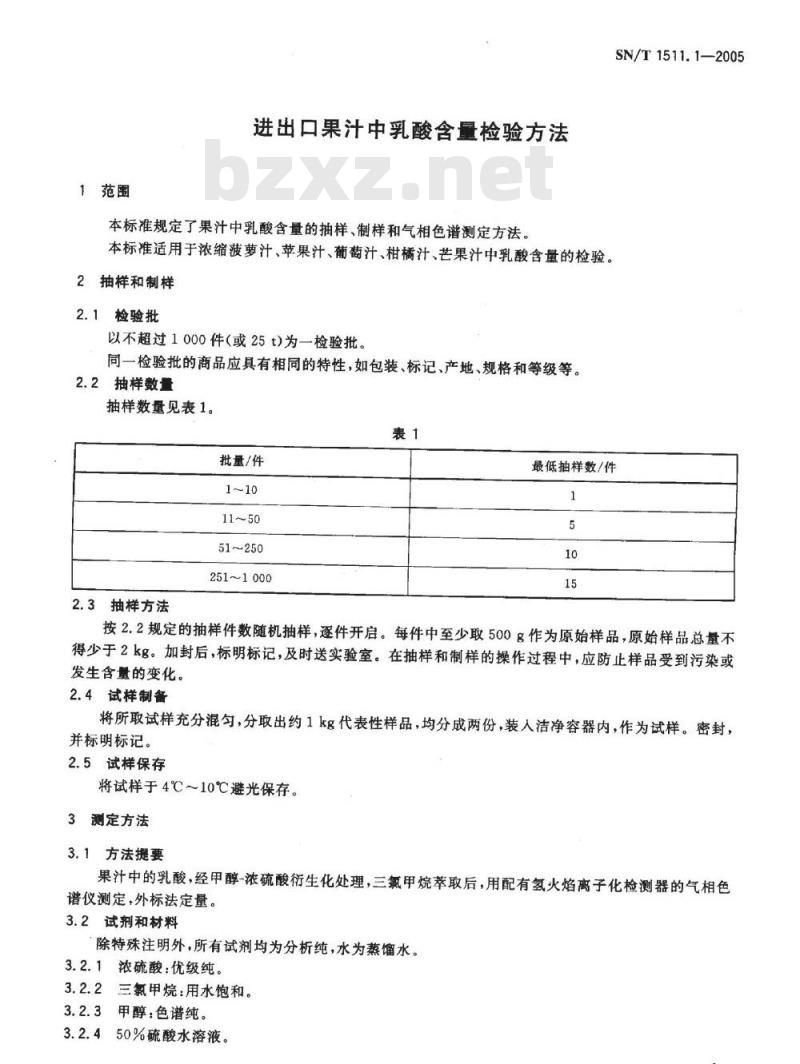

以不超过1000件(或25t)为一检验批。同一检验批的商品应具有相同的特性,如包装、标记、产地、规格和等级等。2.2抽样数量

抽样数量见表1。

批量/件

51~250www.bzxz.net

251~1000

2.3抽样方法

SN/T1511.1—2005

最低抽样数/件

按2.2规定的抽样件数随机抽样,逐件开启。每件中至少取500g作为原始样品,原始样品总量不得少于2kg。加封后,标明标记,及时送实验室。在抽样和制样的操作过程中,应防止样品受到污染或发生含量的变化。

2.4试样制备

将所取试样充分混匀,分取出约1kg代表性样品,均分成两份,装人洁净容器内,作为试样。密封,并标明标记。

2.5试样保存

将试样于4℃~10℃避光保存。

3测定方法

3.1方法提要

果汁中的乳酸,经甲醇-浓硫酸衍生化处理,三氯甲烷萃取后,用配有氢火焰离子化检测器的气相色谱仪测定,外标法定量。

3.2试剂和材料

除特殊注明外,所有试剂均为分析纯,水为蒸馏水。3.2.1浓硫酸:优级纯。

3.2.2三氯甲烷:用水饱和。

3.2.3甲醇:色谱纯。

3.2.450%硫酸水溶液。

SN/T1511.1—2005

3.2.5无水硫酸钠:650℃下灼烧4h,冷却后,储于密闭容器中备用。3.2.6脱脂棉。

3.2.7乳酸锂标准品:纯度≥98.0%,于105℃下干燥4h。3.2.8乳酸标准溶液:1000μg/mL,准确称取0.1067g的乳酸锂标准品,加水溶解至100mL,作为标准储备液。再根据需要用水将标准储备液稀释至适当浓度。3.3仪器和设备

3.3.1气相色谱仪:配氢火焰离子检测器和毛细管分流/不分流进样系统。3.3.2离心机:3000r/min。

3.3.3恒温水浴。

3.3.4具塞离心管:10mL。

3.3.5微量注射器:10μL。

3.3.6玻璃漏斗:30mm(内径)。3.4测定步骤

3.4.1样品处理

称取约1g(精确至0.001g)试样于10mL具塞离心管中,加人0.75mL50%硫酸水溶液,再加人2mL甲醇,摇匀;置于恒温水浴中55℃士1℃衍生化0.5h。取出离心管冷却至室温,加入1mL蒸馏水,摇匀,再准确加人1.0mL三氯甲烷,振摇3min,置于离心机中以3000r/min离心3min,弃去上层水溶液,通过玻璃漏斗(漏斗底部加少许脱脂棉,上铺0.1g无水硫酸钠)滤出下层三氯甲烷萃取液,取三氯甲烷层作GC分析。

3.4.2标准工作液的处理

准确移取0.50mL的乳酸标准工作液,按3.4.1步骤处理。3.4.3空白样品处理

除不加试样外,其余按3.4.1步骤处理。3.4.4测定

3.4.4.1色谱条件

色谱柱:SUPELCOWAX-10或相当,30mX0.32mm(内径)×0.5μma)

程序升温60℃(1.0 min)5/mm-120℃(0.5 min)30c/m250℃(15 min);b)

进样口温度:250℃;

检测器温度:270℃;

载气:氮气,纯度≥99.99%,流量为1.2mL/mine)

氢气流速:37mL/min;

g)空气流速:400mL/min;

尾吹气:30mL/min

进样方式:不分流进样,0.75min后打开分流阀;)

j)进样体积:2μL。

3.4.4.2色谱测定

根据样液中乳酸的含量情况,选定峰面积相近的标准工作溶液。标准工作溶液和样液中乳酸的响应值均应在仪器检测线性范围内。对标准工作溶液和样液等体积参插进样测定,根据色谱峰面积用外标法定量。在上述色谱条件下,乳酸甲酯的保留时间约为10.1min,标准品的气相色谱图参见图A.1。3.5结果计算和表述

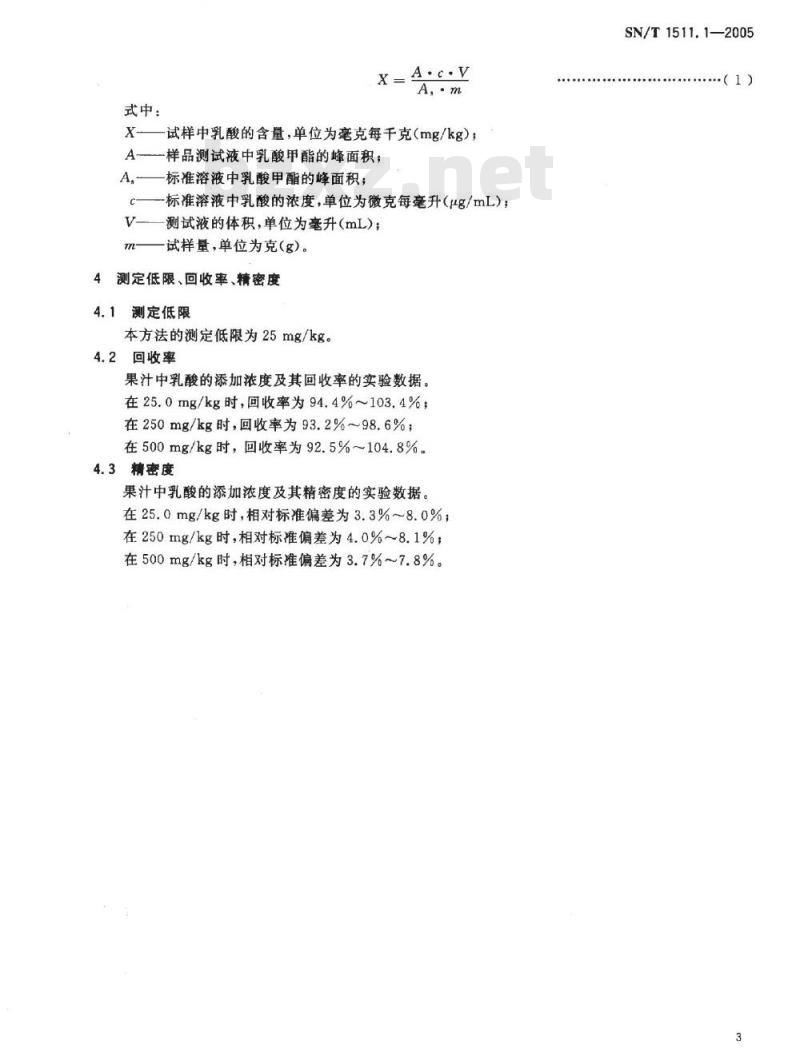

用色谱数据处理机或按式(1)计算试样中乳酸的含量,计算结果需扣除空白值。2

式中:

X一试样中乳酸的含量,单位为毫克每千克(mg/kg);A-样品测试液中乳酸甲酯的峰面积,A

一标准溶液中乳酸甲酯的峰面积;一标准溶液中乳酸的浓度,单位为微克每毫升(μg/mL);V——测试液的体积,单位为毫升(mL);m试样量,单位为克(g)。

4测定低限、回收率、精密度

测定低限

本方法的测定低限为25mg/kg。

4.2回收率

果汁中乳酸的添加浓度及其回收率的实验数据。在25.0mg/kg时,回收率为94.4%~103.4%;在250mg/kg时,回收率为93.2%~98.6%;在500mg/kg时,回收率为92.5%~104.8%。4.3精密度

果汁中乳酸的添加浓度及其精密度的实验数据。在25.0mg/kg时,相对标准偏差为3.3%~8.0%;在250mg/kg时,相对标准偏差为4.0%~8.1%;在500mg/kg时,相对标准偏差为3.7%~7.8%。SN/T 1511.1—2005

.(1)

SN/T 1511.1-2005

附录A

(资料性附录)

标准品的气相色谱图

乳酸标准品的气相色谱图

Forword

AnnexAof this standardwere informativeannex.SN/T1511.1-2005

This standard was proposed byand was underthechargeof the Certification and Accreditation Ad-ministration.

This standard was drafted by Hainan Entry-Exit Inspection and Quarantine Bureau of the People'sRepublicofChina.

The main drafters of this standard are Zhang Weijun, Huang Huiling,Tao Wenging,Jia Zemei,LinDaoying.

This standard is a professional standard promulgated for the first time.Note:ThisEnglishversion,atranslationfromtheChinesetest,issolelyforguidanceSN/T1511.1-2005

Inspection of lactic acid in fruit juice for import and export1

This standard specifies the methods of sampling, sample preparation and determination of lactic acidcontentsinfruitjuicebygaschromatographyThis standard is applicable to the determination of lactic acid contents in concentrate pineapple juice,applejuice,grape juice,orange juice,mangojuice.Samplingandsamplepreparation2

2.1Inspectionlot

Eachinspectionlotshouldnotexceed1oo0packages(or25t).The characteristics ofthe cargo within the same inspection lot,suchas packing,mark,origin,spec-ification and grade, should be the same.2.2Quantityofsampletaken

Quantity of sample taken see Table 1.Table1

Numberof packages inan inspection lot1~10

251~1000

Minimum numberof packages tobetaken5

2.3Samplingprocedure

Draw a number of bags specified in 2.2at random and open the packages oneby one.Take fromeach package should not be less than 5oo g as a primary sample,The total weight of all the primarysample should not be less than 2kg.Place in a sample clean container,seal,label and send to the la-boratory in time, In the course of sampling and sample preparation, precautions must be taken toavoid contamination or any factors which may cause the change of content.2.4Preparationoftestsample

The combined the primary sample is reduced to 1 kg which is blended mixed and divided into twoequal portions,each portion is placed in a clean vessel as a test sample, seald and labeled.6

2.5Storageoftestsample

Thetestsampleshouldbestored4℃~10℃3Methodofdetermination

3.1Principle

SN/T 1511.1—2005

The lactic acid in juice is derived by methanol - sulfuric acid,then extracted by chloroform beforedeterminationbyGCwithFIDdetector.External standardmethod isusedfor quantification3.2 Reagents and materials

Unless otherwise specified,all reagentsused should beanalytical grade,\water\ is distilled water.3.2.1

sulfuric acid.

chloroform:saturatedwithwater.Methanol: chromatography grade.50 % sulfuric acid solution.Anhydrous sodium Sulfate:igniteat 65o for 4h,and store in air-tight container.Absorbendcotton.

Lacticacidlithiumsalt:purity≥98%,driedat105℃for4h.Lactic acid standard solution:Weigh accurately0.1067g standard into a 100 mL volumetricflask.Dissolve and make up to mark with water as the standard stock solution of 1 o0 μg/mL,Dilutethe standard stock solution with water to the required concentration as the standard working solu-tion.

3.3Apparatus and equipment

3.3,1Gas chromatography equipped with FID detectorand capillary split/splitless inject system.3.3.2

Centrifuge:3000 r/min

3.3.3Waterbath:stabletemperature.3.3.4

Centrifugetubes:10 mL,withstopper.Microinjector: 10 μL.

SN/T1511.1—2005

3.3.6Glassfunnel:30mm(i.d.)

3.4Procedure

3.4.1Samplepreparation

Weigh about1g(accurate to0.001g)sample into10mL centrifugewith stopper,add 0.75mL50% sulfuric acid and 2 mL methano1, mix thorughly. Place the tubes into a 55℃ ±1℃ water bathand react for 0.5h.Pick thetube out and cool to room temperature,add 1mL distilled water,shakeand add 1.0 mL chloroform, shake for three minutes. Centrifuge in 3 000 r/min for three minute,discard the water layer,and filter the organic layer with glass funnel though o.1g anhydrous sodiumSulfate and little absorbend cotton. The filtrate of chloroform is used forGC determination.3.4.2Treatmentof standardworkingsolutionPipet accurately o.5o mL of standard working solution of lactic acid, and prepare in according with3.4.1.

3.4.3Blanktest

The operation of the blank test as the same as 3. 4.1 process but it with the omission sample addition.

3.4.4Determination

GCcondition

Column:SUPELCOWAX-10orequivalent,30mx0.32nm(i.d.)x0.5μm;5℃/min-120℃(0.5min)-

30t/min-250℃(15min);

Column temperature:60℃(1.0 min)Injectortemperature:250℃;

Detectortemperature:270℃;

carrygas:nitrogenpurity≥99.99%,flowrate1.2mL/min;e)

Hydrogenflowrate:37mL/min;

g)Airflowrate:400mL/min;

Make-upgas30mL/min;

Injectionmode:splitless,openthesplitvalveato.75minsj)Injectionvolume:2μL

3.4.4.2GC determination

According to the approximate concentration of lactic acid in the sample solution,select the standardworking solution with similar concentration to that of the sample solution. The response of lactidacid in the standard working solution and sample solution should be within the linear range of the in-strumentaldetection,The standardworking solution shouldberandomly injected in-between theinjections of the sample solution of equal volume. External standard method is used for quantifica-tion according to the chromatogram peak area. Under the above GC condition, the retention time oflactic acid in about 1o.1min.The Chromatogram of the standard refertoFigA.1.3.4.4.3Calculationandexpressionoftheresuit8

SN/T1511.1—2005

The calculation of the content of lactic acid in the test sample is carried out by GC data processor oraccording to the formula (1). The blank value should be subtracted from the result of calculation.X=4

Where:

X-the content of lactic acid in sample, mg/kg;A-the peak area of lactic acid in sample test solution;A,the peak area of lactic acid in standard test solution;ctheconcentrationof lacticacid in standard testsolution,μg/mL;thevolumeofthetestsolution,mL;V

-themassof thesample,g.

4 Limit of determination,Recovery and precision4. 1 The limit of determination of this method is 25 mg/kg.4.2Recovery

(1)

The fortifying concentrations of lactic acid in juice concentrate sample and their correspondingrecovery are:

25.0 mg/kg, the recovery 94.4%~103.4%;250mg/kg,the recovery93.2%~98.6%;500 mg/kg,the recovery92.5%~104.8%.4.3Precision

The fortifying concentrations of lactic acid in juice concentrate sample and their corresponding preci-sionare:

25.0mg/kg,therelativestandarddeviation3.3%~8.0%;250 mg/kg, the relative standard deviation 4.0%~8.1%;500mg/kg,therelativestandarddeviation3.7%~7.8%.9

SN/T1511.1—2005

AnnexA

(informative)

Chromatogram of thestandard

Gas Chromatogram of lactic acid standard15

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

进出口果汁中乳酸含量检验方法Inspection of lactic acid in fruit juice for import and export2005-02-17发布

中华人民共和国

国家质量监督检验检疫总局

2005-07-01实施

本标准的附录A为资料性附录。

本标准由国家认证认可监督管理委员会提出并归口。本标准起草单位:中华人民共和国海南出人境检验检疫局。本标准主要起草人:张薇君、黄惠玲、陶文庆、贾泽梅、林道颖。本标准系首次发布的出入境检验检疫行业标准。SN/T1511.1—2005

1范围

进出口果汁中乳酸含量检验方法本标准规定了果汁中乳酸含量的抽样、制样和气相色谱测定方法。本标准适用于浓缩菠萝汁、苹果汁、葡萄汁、柑橘汁、芒果汁中乳酸含量的检验。2抽样和制样

2.1检验批

以不超过1000件(或25t)为一检验批。同一检验批的商品应具有相同的特性,如包装、标记、产地、规格和等级等。2.2抽样数量

抽样数量见表1。

批量/件

51~250www.bzxz.net

251~1000

2.3抽样方法

SN/T1511.1—2005

最低抽样数/件

按2.2规定的抽样件数随机抽样,逐件开启。每件中至少取500g作为原始样品,原始样品总量不得少于2kg。加封后,标明标记,及时送实验室。在抽样和制样的操作过程中,应防止样品受到污染或发生含量的变化。

2.4试样制备

将所取试样充分混匀,分取出约1kg代表性样品,均分成两份,装人洁净容器内,作为试样。密封,并标明标记。

2.5试样保存

将试样于4℃~10℃避光保存。

3测定方法

3.1方法提要

果汁中的乳酸,经甲醇-浓硫酸衍生化处理,三氯甲烷萃取后,用配有氢火焰离子化检测器的气相色谱仪测定,外标法定量。

3.2试剂和材料

除特殊注明外,所有试剂均为分析纯,水为蒸馏水。3.2.1浓硫酸:优级纯。

3.2.2三氯甲烷:用水饱和。

3.2.3甲醇:色谱纯。

3.2.450%硫酸水溶液。

SN/T1511.1—2005

3.2.5无水硫酸钠:650℃下灼烧4h,冷却后,储于密闭容器中备用。3.2.6脱脂棉。

3.2.7乳酸锂标准品:纯度≥98.0%,于105℃下干燥4h。3.2.8乳酸标准溶液:1000μg/mL,准确称取0.1067g的乳酸锂标准品,加水溶解至100mL,作为标准储备液。再根据需要用水将标准储备液稀释至适当浓度。3.3仪器和设备

3.3.1气相色谱仪:配氢火焰离子检测器和毛细管分流/不分流进样系统。3.3.2离心机:3000r/min。

3.3.3恒温水浴。

3.3.4具塞离心管:10mL。

3.3.5微量注射器:10μL。

3.3.6玻璃漏斗:30mm(内径)。3.4测定步骤

3.4.1样品处理

称取约1g(精确至0.001g)试样于10mL具塞离心管中,加人0.75mL50%硫酸水溶液,再加人2mL甲醇,摇匀;置于恒温水浴中55℃士1℃衍生化0.5h。取出离心管冷却至室温,加入1mL蒸馏水,摇匀,再准确加人1.0mL三氯甲烷,振摇3min,置于离心机中以3000r/min离心3min,弃去上层水溶液,通过玻璃漏斗(漏斗底部加少许脱脂棉,上铺0.1g无水硫酸钠)滤出下层三氯甲烷萃取液,取三氯甲烷层作GC分析。

3.4.2标准工作液的处理

准确移取0.50mL的乳酸标准工作液,按3.4.1步骤处理。3.4.3空白样品处理

除不加试样外,其余按3.4.1步骤处理。3.4.4测定

3.4.4.1色谱条件

色谱柱:SUPELCOWAX-10或相当,30mX0.32mm(内径)×0.5μma)

程序升温60℃(1.0 min)5/mm-120℃(0.5 min)30c/m250℃(15 min);b)

进样口温度:250℃;

检测器温度:270℃;

载气:氮气,纯度≥99.99%,流量为1.2mL/mine)

氢气流速:37mL/min;

g)空气流速:400mL/min;

尾吹气:30mL/min

进样方式:不分流进样,0.75min后打开分流阀;)

j)进样体积:2μL。

3.4.4.2色谱测定

根据样液中乳酸的含量情况,选定峰面积相近的标准工作溶液。标准工作溶液和样液中乳酸的响应值均应在仪器检测线性范围内。对标准工作溶液和样液等体积参插进样测定,根据色谱峰面积用外标法定量。在上述色谱条件下,乳酸甲酯的保留时间约为10.1min,标准品的气相色谱图参见图A.1。3.5结果计算和表述

用色谱数据处理机或按式(1)计算试样中乳酸的含量,计算结果需扣除空白值。2

式中:

X一试样中乳酸的含量,单位为毫克每千克(mg/kg);A-样品测试液中乳酸甲酯的峰面积,A

一标准溶液中乳酸甲酯的峰面积;一标准溶液中乳酸的浓度,单位为微克每毫升(μg/mL);V——测试液的体积,单位为毫升(mL);m试样量,单位为克(g)。

4测定低限、回收率、精密度

测定低限

本方法的测定低限为25mg/kg。

4.2回收率

果汁中乳酸的添加浓度及其回收率的实验数据。在25.0mg/kg时,回收率为94.4%~103.4%;在250mg/kg时,回收率为93.2%~98.6%;在500mg/kg时,回收率为92.5%~104.8%。4.3精密度

果汁中乳酸的添加浓度及其精密度的实验数据。在25.0mg/kg时,相对标准偏差为3.3%~8.0%;在250mg/kg时,相对标准偏差为4.0%~8.1%;在500mg/kg时,相对标准偏差为3.7%~7.8%。SN/T 1511.1—2005

.(1)

SN/T 1511.1-2005

附录A

(资料性附录)

标准品的气相色谱图

乳酸标准品的气相色谱图

Forword

AnnexAof this standardwere informativeannex.SN/T1511.1-2005

This standard was proposed byand was underthechargeof the Certification and Accreditation Ad-ministration.

This standard was drafted by Hainan Entry-Exit Inspection and Quarantine Bureau of the People'sRepublicofChina.

The main drafters of this standard are Zhang Weijun, Huang Huiling,Tao Wenging,Jia Zemei,LinDaoying.

This standard is a professional standard promulgated for the first time.Note:ThisEnglishversion,atranslationfromtheChinesetest,issolelyforguidanceSN/T1511.1-2005

Inspection of lactic acid in fruit juice for import and export1

This standard specifies the methods of sampling, sample preparation and determination of lactic acidcontentsinfruitjuicebygaschromatographyThis standard is applicable to the determination of lactic acid contents in concentrate pineapple juice,applejuice,grape juice,orange juice,mangojuice.Samplingandsamplepreparation2

2.1Inspectionlot

Eachinspectionlotshouldnotexceed1oo0packages(or25t).The characteristics ofthe cargo within the same inspection lot,suchas packing,mark,origin,spec-ification and grade, should be the same.2.2Quantityofsampletaken

Quantity of sample taken see Table 1.Table1

Numberof packages inan inspection lot1~10

251~1000

Minimum numberof packages tobetaken5

2.3Samplingprocedure

Draw a number of bags specified in 2.2at random and open the packages oneby one.Take fromeach package should not be less than 5oo g as a primary sample,The total weight of all the primarysample should not be less than 2kg.Place in a sample clean container,seal,label and send to the la-boratory in time, In the course of sampling and sample preparation, precautions must be taken toavoid contamination or any factors which may cause the change of content.2.4Preparationoftestsample

The combined the primary sample is reduced to 1 kg which is blended mixed and divided into twoequal portions,each portion is placed in a clean vessel as a test sample, seald and labeled.6

2.5Storageoftestsample

Thetestsampleshouldbestored4℃~10℃3Methodofdetermination

3.1Principle

SN/T 1511.1—2005

The lactic acid in juice is derived by methanol - sulfuric acid,then extracted by chloroform beforedeterminationbyGCwithFIDdetector.External standardmethod isusedfor quantification3.2 Reagents and materials

Unless otherwise specified,all reagentsused should beanalytical grade,\water\ is distilled water.3.2.1

sulfuric acid.

chloroform:saturatedwithwater.Methanol: chromatography grade.50 % sulfuric acid solution.Anhydrous sodium Sulfate:igniteat 65o for 4h,and store in air-tight container.Absorbendcotton.

Lacticacidlithiumsalt:purity≥98%,driedat105℃for4h.Lactic acid standard solution:Weigh accurately0.1067g standard into a 100 mL volumetricflask.Dissolve and make up to mark with water as the standard stock solution of 1 o0 μg/mL,Dilutethe standard stock solution with water to the required concentration as the standard working solu-tion.

3.3Apparatus and equipment

3.3,1Gas chromatography equipped with FID detectorand capillary split/splitless inject system.3.3.2

Centrifuge:3000 r/min

3.3.3Waterbath:stabletemperature.3.3.4

Centrifugetubes:10 mL,withstopper.Microinjector: 10 μL.

SN/T1511.1—2005

3.3.6Glassfunnel:30mm(i.d.)

3.4Procedure

3.4.1Samplepreparation

Weigh about1g(accurate to0.001g)sample into10mL centrifugewith stopper,add 0.75mL50% sulfuric acid and 2 mL methano1, mix thorughly. Place the tubes into a 55℃ ±1℃ water bathand react for 0.5h.Pick thetube out and cool to room temperature,add 1mL distilled water,shakeand add 1.0 mL chloroform, shake for three minutes. Centrifuge in 3 000 r/min for three minute,discard the water layer,and filter the organic layer with glass funnel though o.1g anhydrous sodiumSulfate and little absorbend cotton. The filtrate of chloroform is used forGC determination.3.4.2Treatmentof standardworkingsolutionPipet accurately o.5o mL of standard working solution of lactic acid, and prepare in according with3.4.1.

3.4.3Blanktest

The operation of the blank test as the same as 3. 4.1 process but it with the omission sample addition.

3.4.4Determination

GCcondition

Column:SUPELCOWAX-10orequivalent,30mx0.32nm(i.d.)x0.5μm;5℃/min-120℃(0.5min)-

30t/min-250℃(15min);

Column temperature:60℃(1.0 min)Injectortemperature:250℃;

Detectortemperature:270℃;

carrygas:nitrogenpurity≥99.99%,flowrate1.2mL/min;e)

Hydrogenflowrate:37mL/min;

g)Airflowrate:400mL/min;

Make-upgas30mL/min;

Injectionmode:splitless,openthesplitvalveato.75minsj)Injectionvolume:2μL

3.4.4.2GC determination

According to the approximate concentration of lactic acid in the sample solution,select the standardworking solution with similar concentration to that of the sample solution. The response of lactidacid in the standard working solution and sample solution should be within the linear range of the in-strumentaldetection,The standardworking solution shouldberandomly injected in-between theinjections of the sample solution of equal volume. External standard method is used for quantifica-tion according to the chromatogram peak area. Under the above GC condition, the retention time oflactic acid in about 1o.1min.The Chromatogram of the standard refertoFigA.1.3.4.4.3Calculationandexpressionoftheresuit8

SN/T1511.1—2005

The calculation of the content of lactic acid in the test sample is carried out by GC data processor oraccording to the formula (1). The blank value should be subtracted from the result of calculation.X=4

Where:

X-the content of lactic acid in sample, mg/kg;A-the peak area of lactic acid in sample test solution;A,the peak area of lactic acid in standard test solution;ctheconcentrationof lacticacid in standard testsolution,μg/mL;thevolumeofthetestsolution,mL;V

-themassof thesample,g.

4 Limit of determination,Recovery and precision4. 1 The limit of determination of this method is 25 mg/kg.4.2Recovery

(1)

The fortifying concentrations of lactic acid in juice concentrate sample and their correspondingrecovery are:

25.0 mg/kg, the recovery 94.4%~103.4%;250mg/kg,the recovery93.2%~98.6%;500 mg/kg,the recovery92.5%~104.8%.4.3Precision

The fortifying concentrations of lactic acid in juice concentrate sample and their corresponding preci-sionare:

25.0mg/kg,therelativestandarddeviation3.3%~8.0%;250 mg/kg, the relative standard deviation 4.0%~8.1%;500mg/kg,therelativestandarddeviation3.7%~7.8%.9

SN/T1511.1—2005

AnnexA

(informative)

Chromatogram of thestandard

Gas Chromatogram of lactic acid standard15

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

标准图片预览:

- 热门标准

- 商检行业标准(SN)

- SN/T1473-2004 兔粘液瘤病琼脂免疫扩散试验操作规程

- SN/T1358.2-2005 马传染性贫血琼脂凝胶免疫扩散试验操作规程

- SN/T1853-2006 进出口两轮全场地车检验规程

- SN/T1673-2005 对虾传染性皮下和造血器官坏死病毒聚合酶链反应操作规程

- SN/T1467-2004 小鹅瘟病毒分离和琼脂免疫扩散试验方法

- SN/T2358-2009 国境口岸炭疽芽胞杆菌荧光定量PCR检测方法

- SN/T2269-2009 进出口贝肉中大田软海绵酸的检测 液相色谱-串联质谱法

- SN/T1889.4-2007 杀灭进出口食品中有害微生物最低辐照剂量 第4部分:黄曲霉

- SN/T1932.7-2008 进出口服装检验规程 第7部分:衬衫

- SN/T2552.11-2010 乳及乳制品卫生微生物学检验方法 第11部分:蜡样芽胞杆菌的分离与计数

- SN/T0057-1992 进口化纤长丝断裂强力和断裂伸长的测定

- SN/T1874-2007 猪细小病毒病聚合酶链反应操作规程

- SN/T1889.1-2007 杀灭进出口食品中有害微生物最低辐照剂量 第1部分:串珠镰刀菌

- SN/T2055-2016 豇豆重花叶病毒检疫鉴定方法

- SN/T2426-2010 进出口粮谷中桔霉素含量检测方法 液相色谱法

- 行业新闻

- Sidus Heroes元宇宙:SIDUS代币如何助力P2E游戏生态?

- 顶级分析师表示XRP长期走势图表现极佳,建议在XRP上设置买入点位

- 比特币因需求减弱而停滞——这对BTC的下一步意味着什么

- XRP律师驳斥Ripple vs SEC案将拖延至2026年的传闻

- 2025 虚拟资产大未来:衍生性商品监理政策论坛 7/8 登场

- 随着杠杆率攀升,ETH跌破2400美元,目标价下看2155美元

- DIA质押启动引发15条以上链免费预言机接入

- 卡尔达诺向比特币持有者发起挑战,霍斯金森准备豪赌数百万枚ADA,证明比特币持有者可在卡尔达诺上赚取被动收入

- TRUMP Meme Coin团队向币安转移3280万美元

- 加密货币市场每周赢家和输家 – KAIA、BCH、SPX、FARTCOIN

- 美国特勤局宣布在"杀猪盘"案件中查获史上最大加密货币

- 2025年6月24日卡尔达诺(ADA)价格预测

- 鲸鱼在比特币清算中损失350万美元,后以40倍杠杆做多获利106万美元反弹

- 为什么比特币、股票和黄金都创下新高:背后的驱动因素解析

- 狮城控股集团获得6亿美元资金,用于构建以超流动性为重点的国库策略

请牢记:“bzxz.net”即是“标准下载”四个汉字汉语拼音首字母与国际顶级域名“.net”的组合。 ©2009 标准下载网 www.bzxz.net 本站邮件:bzxznet@163.com

网站备案号:湘ICP备2023016450号-1

网站备案号:湘ICP备2023016450号-1