- 您的位置:

- 标准下载网 >>

- 标准分类 >>

- 商检行业标准(SN) >>

- SN/T 1774-2006 进出口茶叶中八氯二丙醚残留量检测方法 气相色谱法

标准号:

SN/T 1774-2006

标准名称:

进出口茶叶中八氯二丙醚残留量检测方法 气相色谱法

标准类别:

商检行业标准(SN)

标准状态:

现行-

发布日期:

2006-04-25 -

实施日期:

2006-11-15 出版语种:

简体中文下载格式:

.rar.pdf下载大小:

206.05 KB

点击下载

标准简介:

标准下载解压密码:www.bzxz.net

本标准规定了进出口茶叶中八氯二丙醚残留量测定的制样和气相色谱测定方法。本标准适用于进出口茶叶中八氯二丙醚残留量的测定。 SN/T 1774-2006 进出口茶叶中八氯二丙醚残留量检测方法 气相色谱法 SN/T1774-2006

部分标准内容:

中华人民共和国出入境检验检疫行业标准SN/T 1774—2006

进出口茶叶中八氯二丙醚残留量气相色谱法

检测方法

Determination of Octachlorodipropyl ether residue in tea forimport and exportGas chromatographic method2006-04-25发布

中华人民共和国

国家质量监督检验检疫总局

2006-11-15实施

本标准的附录A为资料性附录,

本标准出国家认证认可监督管理委员会提出并归口本标准起草单位:中华人民共和国渐江出人境检验检疫局。本标准主要起草人:丁璜,谢文、章晓氧、将晓英、曾若茗雪。本标准系首次发布的出入境检验检疫行业标准。SN/T1774—2006

1范围

进出口茶叶中八氯二丙醚残留量检测方法气相色谱法

SN/T 1774—2006

木标规定了进出口茶叶中八氯二丙醚残留最测定的制样和气相色谱测定方法。本标适用于进出口茶吓中八氯二丙醚残留量的测定。2制样

将全部样品充分拌勺,磨碎,通过孔径为0.85-mm的筛(20月),均分成两份,装人洁净的容器内作为试样。密封,并标明标记。在制样的操作过程中,应防止样品受到污染或发牛残留物含量的变化。将试样室温保存。3测定方法

3.1方法提要

样品中的八氯二丙残留用丙酮和水提取,再经正已烷反萃取,然后用浓硫酸磺化净化,用配有电子俘获检测器的气相色谱仪测定,外标法定量。3.2试剂和材料

除有规定外,所用试剂均为分析纯,水为蒸水。3.21正已烷:色纯。

3.2.2丙酮:色谱纯。

3.2.3氟化钠水溶液:150g/L。

3.2.4浓硫酸。

3.2.5无水硫酸钢:650℃灼烧4h,在干燥器冷却至室温,储于密封瓶中备用。3.2.6八氯二内醚标准品:纯度大于99%。3.2.7八氯二丙醚标准储备溶液:称取0.01000g八氯二内醚标准品(3.2.6),用正已烷溶解定容至100ⅡL,此溶液浓度为100ug/mL。存放在4℃的冰箱。柜据带要用正己烷稀至适当浓度的标准工作液。

3.3仪器和设备

3.3.1气相色谱仪,配有电子俘获检测器。3.3.2旋转蒸发器。

3.3.3均质器。

3.3.4无水硫酸钠柱:80mm×40mm(内径)简型漏斗,底部势约5mm高脱脂棉,再装约50mml高无水硫酸钠(3.2.5)。

3.4定步骤

3,4.1提取

称圾3g试样(精确到0.01g)置于100mL烧杯中,加人10mL水浸泡2h,入20mL内酮,在均质器中均质2min。过滤至预先装有50mL氯化钠水溶液(3.2.3)和20mL正已烷的250mlL分液漏斗中,用10 IL左右内酮清洗残渣,合并滤液。剧烈振摇,静置分层。分离正己烷相。水相中再加入20ml.正已烷,重复操作,合非正己烷相,过无水硫酸钠柱(3.3.4)至液缩瓶中,用少量止已烷清洗此柱,1

SN/T1774—2006

用旋转蒸发器在45℃以下水济减压浓缩至近下。3.4.2净化

浓缩瓶中残留物用2mL止也烷溶解,转移人离心管中,浓缩瓶中再划2mL正已烷,重复操作一次。氮气吹干,准确加入3.0mL正已烷,0.5mE浓硫酸。振摇,以4000r/min离心2min,用尖嘴吸管吸取下层,弃去。止已烷层再加人0.5mL浓硫酸,重复操作,直到止己烷层无色。正已烷溶液供GC测定。

3.4.3测定

3. 4. 3. 1色谱条件

色谱柱:石英毛细管柱,DB.180mX0.25mm(直径)×0.25μm膜厚),或相当者a

找气和尾吹气:氮气(纯度大于99.999%),载气流量:1.0mL/min,尾吹气流质:30mL/min)

柱温:初始温度70℃保持1min,以10℃/min升至280℃,保持min进样口温度;200°℃;

检测器温度:300℃:

进样方式:不分流进样;

g)开阅时间;l mint

h)进样最:μL。

3.4.3.2色谱测定

根据样液中八氧二丙醒含量的情况,选定浓度相近的标推工作溶,标准工作溶液和样液中的八氯二丙醚响应值应在仪器检测的线性范围内。标准工作溶液和样液等体积穿插进样测定。八氧二内醚标准品的气相色谱图参见附录A中图A.1。3. 4. 3. 3空自试验

除不加试样外,均按上述操作步骤进行。在满足试剂纯度、仪器工作和实验环境正常条件下,空白试验应无于扰择出现。

3.4.3.4结果计算和表述

用色谱数据处理机或按式(1)计算试样中八氯二丙醚的残留含量:AXe×V

式中:

X—-试样中八氯二丙醚的残留量,单位为毫克每千克(mg/kg);A

-样液中八氯三丙醚的峰面积,

As—标推工作被中八氯二丙醚的峰面积标准工作液八氯二丙醚的浓度,单位为微克每毫升(ug/mL);V.

样液最终定容体积,单位为毫升(mL),最终样液所代表的试样质益,单位为克(),4测定低限和回收率

4.1测定低限

本方法的测定低限为 0. 01 1ig/kg4.2回收率

回收率的实验数据如下,

八氯二内醚添加浓度在0.01mg/kg时,回收率为90%~114%:八氯二丙醚添加浓度在0.02mg/kg时,回收率为97头~108%,八氮二丙醚添加浓度在 0.20 mg/kg时,回收率为 91%~110%。2

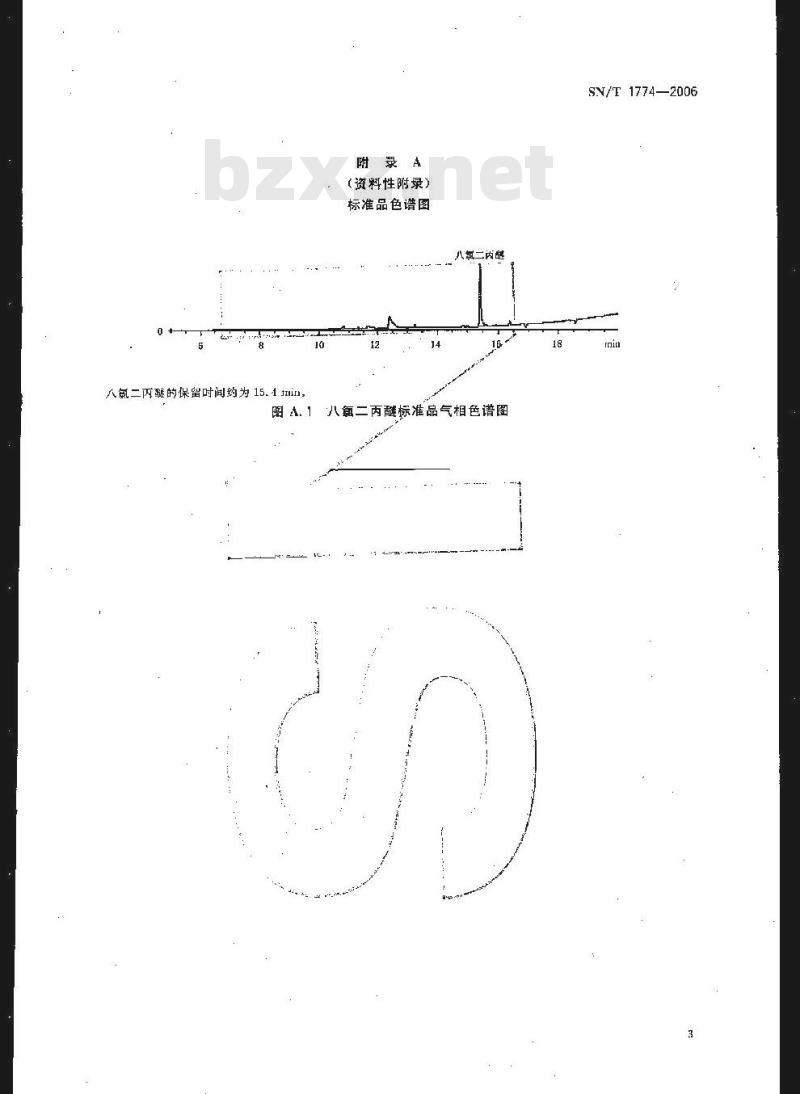

八氛二丙醚的保留时间约为15.4min10

附录A

(资料性附录)

标准品色谱图

八鼠二丙髓

八氧二丙醚标准品气相色谱图

SV/T1774—2006

SN/T1774-2006

Foreword

Annex A of.this stardard is an informative annex.This standard was proposed by and is under the charged of The Certification and Accreditation Ad-ministration of the People's Republic of China.This standard was drafted by Zhejiang Entry - Exit Inspection and Quarantine Bureau.The standard was mainly drafted by Ding Huiying,XieWen,Zhang XiaoDong,Jiang XiaoYing,ZengRuo Xue.

This standard is a professional standard for entry-exit inspection and quarantine promulgated for thefirst time.

SN/T 1774—2006

Determination of Octachlorodipropyl ether residue in tea forimport and export-Gas chromatographic method1Scope

This standard specifies the methods of sample reparation and determination by gas chromatography(Gc) of octachlorodipropyl ether rasidue in teaa for export and import.This standard is applicable to the determination ofoctachlorodipropyl ether residues in tea for exportand import.

2 Preparation of test sampleThe mixed primary sample is crushad with a grinder or martar until throughly crushed and wholypassed through a 0. 85 mm( id) sieve (20 mesh) , and then divided into two equal portions. Each por-tian is placad in a clean containar as the test sample, which is then sealed and labled.In the course of sarmpling and sample preparation,precautions must be taken to avoid contaminationor any factors which may cause the change of residue content. The test samples should be stored atraom temperature.

3 Method of determination

3, 1Principle

octachiorodipropyl ether residue are extracted from the tea sample by acetone, and re-extracted byhexane, and cleaned up with sulfuric acid. The solution is used for Gc-ECD determination, Externalstandard method is used for quantitative measurement.3. 2 Reagents and materials

Unless otherwise specified, all the reagent used should be analytical grade, \water\ is distilled wa-ter.

3. 2. 1 n-hexane: HPLC grade.3.2.2acetone;HPLC grade.

SN/T 1774--2006

3.2.3Sadiumchlaridesolution150g/L3:2.4 Suifuric acid.

3. 2.5 Anhydrous sodium sutfate: ignite for 4 h at 650'C, and keep in a tightly classd container.3, 2. 6 Satandard of octachlorodipropyl ether: purity>99%.3.2.7 Stock satandard solution of octachlorodipropyl ether: accurately weight 0. 010 00 g Satan-dard(3. 2. 6) ,dissolve witirT-nexane and quantitatively on 100 mL, thd concentration of solution is10o μg/mL. The solutian shall be stored in 4℃ refrigeratory. According to the requirement, is pre-pared from the stock standard salution by n-hexane and diluted' to the required concentration.3.3Apparatus and equipment

3.3.1Gas chromatography, equipped with electron capture detector.Rotaryvacuumevaporator.

3. 3. 3High spead blernde

Column of anhydrous sodium sulfate: 80 mm × 40 mm(id) cylinder funnel,pack with ca3. 3. 4

5 mm absorbent cotton at the bottom of the column and fill in 5o mm anhydrous sodium sulfate(3. 2. 5).

3. 4Procedure.

Extraction

Weigh ca 3 g of the test.samble (accurate to 0. 01g) into a 100mL beaker. Add 10 ml water andstand to 2 hours. Add 20 mL acetone, mixed 2 min in high speedt blender, filter the extracted solu.tion with a filter paper,into a 25o mL separatory funnel which is added 50 mL sodium chloride solu-tion(3. 2. 3) and 20 mL n-hexane, use 10 mL aceton to rinse fiter paper, shake vigorously for 2 min,let stand to separating, collet n-hexane layer. Add 25 mL n-hexane to water layer, repeat the opera-tion again. Combine the n-hexane layers through column' of anhydrous sodium sulfate(3. 3, 4) into a100mL round battom flask and use nhexape to rinse the column. Combine thesolution and evaporateto nearly dryness at rotary vacuum evaporator bleow 45c3.4. 2 Clean up

Add 2 mL n-haxane and 2 mL n-hexane to dissolve the residue of the round bottom flask, transferthe abave solution into 10 mL centrifuge tube with stopper, blow just dryness with N, gas, Add ex-.6

SN/T 1774—2006

actly 3. 0 mL n-hexane and 0. 5 mL sulfuric acid into the 10 mL centrifuge tube. The 10 ml centritugetube is shaked, and centrifuged for 2 min under 4 o00 r/min. The down layer is discarded with pipet,repeat the procedure again until the n-hexane layer is colourless. The n-hexane is ready for Gc deter.mination

3.4. 3Determination

3. 4. 3. 1 Gc operating conditionChromatographic column: Fused siltica cepillary column, DB-1 30 m× 0, 25 mm (id) × 0. 25 μma)

(filmthickness) or equivalent,Carrier gas and make-up gas: 'Nitrogen (purity ≥ 99. 999%)i Flaw rate at carrier gas:b)

1.0 mL/min, flow rate of make-up gas: 30 mL/mintsc)

Temperatureprogramme:70℃(1min),10℃/minto280℃(5min)Injectionporttemperature20o'c;Detector temperature:300℃,

Injection mode: Splitless;

Purge valve: 1 min on;

Injection valume: 1 μL.

3.4.3.2GC determination

According to the concentrations of actachlorodipropyl ether, select the standard working solutionwith similar peak area to that of sample solution. The responses of octachlorodipropyl ether in thestandard working solution and the sample solution should be within the linaar range of the instrumen-tal detection. The standard working solution should be randornly Injected in between the injections ofsample solution of equal yolume. Under ths abave GC operating condition, For chromatogram of thestandard seeFigureA1 inannexA,3. 4. 3.3Blank test

The operation of the blank test is the'sarme as the described in the method of determination, but withthe omission of sample addition. If the solvent purity,instrument and test environment conditions

mest demands, blank test should not have disturbing peaks.3.4.3.4

Calculationandexpressionof resuitCalculation the content of octachlorodipropyl ether residue in-the test sample by GC data processoror according to the formula(1):AxcxV

-the residue content of octachlorodipropyl ether in the test sample, mg/kg;(1)

SN/T1774—2006

A---the peak area of octachlorodipropyl ether in sample solution;As

the paak area of octachlorodipropyl ethar in standard working solution;-theconcentrationofoctachiorodipropyletherinworkingsolution,μg/mL;Vthe final volume of thesample solution,mL;m -mass of test sample, g.

Limit of determination and recovery4.1Limit of determination

The limit af determinatian of this method is 0, o1 mg/kg.4.2 Recovery

According to the experimental data,the carresponding recoveries of fortifying concentrations are:octachlorodipropyletherspike0.01mg/kg,therecoveryis90%~114%octachlorodipropyl ether spike 0. 02 mg/kg, tha récovery is 97% ~ 108%.octachlorodipropyletherspike0.2mg/kg,therecoveryis91%~110%.8

Annex A

(informative)

Chromatogram of the stardardoctachlorodipromyl ether

SN/T1774—2006

the retention time of octachlarodipropyl ether is about 15.4 min.Gas chromatogram of octachlorodlpropyl ether standardFigureA. 1

SN/T 1774-2006

中华人民共和国出人境检验检疫行业标翟

进出口茶叶中八氯二丙醚残留量捡测方法气相色谱法

SN/T 1774-- 2006

中国标准出版社出版

北京复兴门外三里河北街16号

邮政码:100045

网址uzchs.con下载标准就来标准下载网

电话:6852394668517548

中国标准出版社泰皇舟印刷厂印开本880×12301/门6印张1字数16千字2006年8月第一版2006年8儿第一次印刷印数1—2000

书号:155065,2-17038定价10.00元

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

进出口茶叶中八氯二丙醚残留量气相色谱法

检测方法

Determination of Octachlorodipropyl ether residue in tea forimport and exportGas chromatographic method2006-04-25发布

中华人民共和国

国家质量监督检验检疫总局

2006-11-15实施

本标准的附录A为资料性附录,

本标准出国家认证认可监督管理委员会提出并归口本标准起草单位:中华人民共和国渐江出人境检验检疫局。本标准主要起草人:丁璜,谢文、章晓氧、将晓英、曾若茗雪。本标准系首次发布的出入境检验检疫行业标准。SN/T1774—2006

1范围

进出口茶叶中八氯二丙醚残留量检测方法气相色谱法

SN/T 1774—2006

木标规定了进出口茶叶中八氯二丙醚残留最测定的制样和气相色谱测定方法。本标适用于进出口茶吓中八氯二丙醚残留量的测定。2制样

将全部样品充分拌勺,磨碎,通过孔径为0.85-mm的筛(20月),均分成两份,装人洁净的容器内作为试样。密封,并标明标记。在制样的操作过程中,应防止样品受到污染或发牛残留物含量的变化。将试样室温保存。3测定方法

3.1方法提要

样品中的八氯二丙残留用丙酮和水提取,再经正已烷反萃取,然后用浓硫酸磺化净化,用配有电子俘获检测器的气相色谱仪测定,外标法定量。3.2试剂和材料

除有规定外,所用试剂均为分析纯,水为蒸水。3.21正已烷:色纯。

3.2.2丙酮:色谱纯。

3.2.3氟化钠水溶液:150g/L。

3.2.4浓硫酸。

3.2.5无水硫酸钢:650℃灼烧4h,在干燥器冷却至室温,储于密封瓶中备用。3.2.6八氯二内醚标准品:纯度大于99%。3.2.7八氯二丙醚标准储备溶液:称取0.01000g八氯二内醚标准品(3.2.6),用正已烷溶解定容至100ⅡL,此溶液浓度为100ug/mL。存放在4℃的冰箱。柜据带要用正己烷稀至适当浓度的标准工作液。

3.3仪器和设备

3.3.1气相色谱仪,配有电子俘获检测器。3.3.2旋转蒸发器。

3.3.3均质器。

3.3.4无水硫酸钠柱:80mm×40mm(内径)简型漏斗,底部势约5mm高脱脂棉,再装约50mml高无水硫酸钠(3.2.5)。

3.4定步骤

3,4.1提取

称圾3g试样(精确到0.01g)置于100mL烧杯中,加人10mL水浸泡2h,入20mL内酮,在均质器中均质2min。过滤至预先装有50mL氯化钠水溶液(3.2.3)和20mL正已烷的250mlL分液漏斗中,用10 IL左右内酮清洗残渣,合并滤液。剧烈振摇,静置分层。分离正己烷相。水相中再加入20ml.正已烷,重复操作,合非正己烷相,过无水硫酸钠柱(3.3.4)至液缩瓶中,用少量止已烷清洗此柱,1

SN/T1774—2006

用旋转蒸发器在45℃以下水济减压浓缩至近下。3.4.2净化

浓缩瓶中残留物用2mL止也烷溶解,转移人离心管中,浓缩瓶中再划2mL正已烷,重复操作一次。氮气吹干,准确加入3.0mL正已烷,0.5mE浓硫酸。振摇,以4000r/min离心2min,用尖嘴吸管吸取下层,弃去。止已烷层再加人0.5mL浓硫酸,重复操作,直到止己烷层无色。正已烷溶液供GC测定。

3.4.3测定

3. 4. 3. 1色谱条件

色谱柱:石英毛细管柱,DB.180mX0.25mm(直径)×0.25μm膜厚),或相当者a

找气和尾吹气:氮气(纯度大于99.999%),载气流量:1.0mL/min,尾吹气流质:30mL/min)

柱温:初始温度70℃保持1min,以10℃/min升至280℃,保持min进样口温度;200°℃;

检测器温度:300℃:

进样方式:不分流进样;

g)开阅时间;l mint

h)进样最:μL。

3.4.3.2色谱测定

根据样液中八氧二丙醒含量的情况,选定浓度相近的标推工作溶,标准工作溶液和样液中的八氯二丙醚响应值应在仪器检测的线性范围内。标准工作溶液和样液等体积穿插进样测定。八氧二内醚标准品的气相色谱图参见附录A中图A.1。3. 4. 3. 3空自试验

除不加试样外,均按上述操作步骤进行。在满足试剂纯度、仪器工作和实验环境正常条件下,空白试验应无于扰择出现。

3.4.3.4结果计算和表述

用色谱数据处理机或按式(1)计算试样中八氯二丙醚的残留含量:AXe×V

式中:

X—-试样中八氯二丙醚的残留量,单位为毫克每千克(mg/kg);A

-样液中八氯三丙醚的峰面积,

As—标推工作被中八氯二丙醚的峰面积标准工作液八氯二丙醚的浓度,单位为微克每毫升(ug/mL);V.

样液最终定容体积,单位为毫升(mL),最终样液所代表的试样质益,单位为克(),4测定低限和回收率

4.1测定低限

本方法的测定低限为 0. 01 1ig/kg4.2回收率

回收率的实验数据如下,

八氯二内醚添加浓度在0.01mg/kg时,回收率为90%~114%:八氯二丙醚添加浓度在0.02mg/kg时,回收率为97头~108%,八氮二丙醚添加浓度在 0.20 mg/kg时,回收率为 91%~110%。2

八氛二丙醚的保留时间约为15.4min10

附录A

(资料性附录)

标准品色谱图

八鼠二丙髓

八氧二丙醚标准品气相色谱图

SV/T1774—2006

SN/T1774-2006

Foreword

Annex A of.this stardard is an informative annex.This standard was proposed by and is under the charged of The Certification and Accreditation Ad-ministration of the People's Republic of China.This standard was drafted by Zhejiang Entry - Exit Inspection and Quarantine Bureau.The standard was mainly drafted by Ding Huiying,XieWen,Zhang XiaoDong,Jiang XiaoYing,ZengRuo Xue.

This standard is a professional standard for entry-exit inspection and quarantine promulgated for thefirst time.

SN/T 1774—2006

Determination of Octachlorodipropyl ether residue in tea forimport and export-Gas chromatographic method1Scope

This standard specifies the methods of sample reparation and determination by gas chromatography(Gc) of octachlorodipropyl ether rasidue in teaa for export and import.This standard is applicable to the determination ofoctachlorodipropyl ether residues in tea for exportand import.

2 Preparation of test sampleThe mixed primary sample is crushad with a grinder or martar until throughly crushed and wholypassed through a 0. 85 mm( id) sieve (20 mesh) , and then divided into two equal portions. Each por-tian is placad in a clean containar as the test sample, which is then sealed and labled.In the course of sarmpling and sample preparation,precautions must be taken to avoid contaminationor any factors which may cause the change of residue content. The test samples should be stored atraom temperature.

3 Method of determination

3, 1Principle

octachiorodipropyl ether residue are extracted from the tea sample by acetone, and re-extracted byhexane, and cleaned up with sulfuric acid. The solution is used for Gc-ECD determination, Externalstandard method is used for quantitative measurement.3. 2 Reagents and materials

Unless otherwise specified, all the reagent used should be analytical grade, \water\ is distilled wa-ter.

3. 2. 1 n-hexane: HPLC grade.3.2.2acetone;HPLC grade.

SN/T 1774--2006

3.2.3Sadiumchlaridesolution150g/L3:2.4 Suifuric acid.

3. 2.5 Anhydrous sodium sutfate: ignite for 4 h at 650'C, and keep in a tightly classd container.3, 2. 6 Satandard of octachlorodipropyl ether: purity>99%.3.2.7 Stock satandard solution of octachlorodipropyl ether: accurately weight 0. 010 00 g Satan-dard(3. 2. 6) ,dissolve witirT-nexane and quantitatively on 100 mL, thd concentration of solution is10o μg/mL. The solutian shall be stored in 4℃ refrigeratory. According to the requirement, is pre-pared from the stock standard salution by n-hexane and diluted' to the required concentration.3.3Apparatus and equipment

3.3.1Gas chromatography, equipped with electron capture detector.Rotaryvacuumevaporator.

3. 3. 3High spead blernde

Column of anhydrous sodium sulfate: 80 mm × 40 mm(id) cylinder funnel,pack with ca3. 3. 4

5 mm absorbent cotton at the bottom of the column and fill in 5o mm anhydrous sodium sulfate(3. 2. 5).

3. 4Procedure.

Extraction

Weigh ca 3 g of the test.samble (accurate to 0. 01g) into a 100mL beaker. Add 10 ml water andstand to 2 hours. Add 20 mL acetone, mixed 2 min in high speedt blender, filter the extracted solu.tion with a filter paper,into a 25o mL separatory funnel which is added 50 mL sodium chloride solu-tion(3. 2. 3) and 20 mL n-hexane, use 10 mL aceton to rinse fiter paper, shake vigorously for 2 min,let stand to separating, collet n-hexane layer. Add 25 mL n-hexane to water layer, repeat the opera-tion again. Combine the n-hexane layers through column' of anhydrous sodium sulfate(3. 3, 4) into a100mL round battom flask and use nhexape to rinse the column. Combine thesolution and evaporateto nearly dryness at rotary vacuum evaporator bleow 45c3.4. 2 Clean up

Add 2 mL n-haxane and 2 mL n-hexane to dissolve the residue of the round bottom flask, transferthe abave solution into 10 mL centrifuge tube with stopper, blow just dryness with N, gas, Add ex-.6

SN/T 1774—2006

actly 3. 0 mL n-hexane and 0. 5 mL sulfuric acid into the 10 mL centrifuge tube. The 10 ml centritugetube is shaked, and centrifuged for 2 min under 4 o00 r/min. The down layer is discarded with pipet,repeat the procedure again until the n-hexane layer is colourless. The n-hexane is ready for Gc deter.mination

3.4. 3Determination

3. 4. 3. 1 Gc operating conditionChromatographic column: Fused siltica cepillary column, DB-1 30 m× 0, 25 mm (id) × 0. 25 μma)

(filmthickness) or equivalent,Carrier gas and make-up gas: 'Nitrogen (purity ≥ 99. 999%)i Flaw rate at carrier gas:b)

1.0 mL/min, flow rate of make-up gas: 30 mL/mintsc)

Temperatureprogramme:70℃(1min),10℃/minto280℃(5min)Injectionporttemperature20o'c;Detector temperature:300℃,

Injection mode: Splitless;

Purge valve: 1 min on;

Injection valume: 1 μL.

3.4.3.2GC determination

According to the concentrations of actachlorodipropyl ether, select the standard working solutionwith similar peak area to that of sample solution. The responses of octachlorodipropyl ether in thestandard working solution and the sample solution should be within the linaar range of the instrumen-tal detection. The standard working solution should be randornly Injected in between the injections ofsample solution of equal yolume. Under ths abave GC operating condition, For chromatogram of thestandard seeFigureA1 inannexA,3. 4. 3.3Blank test

The operation of the blank test is the'sarme as the described in the method of determination, but withthe omission of sample addition. If the solvent purity,instrument and test environment conditions

mest demands, blank test should not have disturbing peaks.3.4.3.4

Calculationandexpressionof resuitCalculation the content of octachlorodipropyl ether residue in-the test sample by GC data processoror according to the formula(1):AxcxV

-the residue content of octachlorodipropyl ether in the test sample, mg/kg;(1)

SN/T1774—2006

A---the peak area of octachlorodipropyl ether in sample solution;As

the paak area of octachlorodipropyl ethar in standard working solution;-theconcentrationofoctachiorodipropyletherinworkingsolution,μg/mL;Vthe final volume of thesample solution,mL;m -mass of test sample, g.

Limit of determination and recovery4.1Limit of determination

The limit af determinatian of this method is 0, o1 mg/kg.4.2 Recovery

According to the experimental data,the carresponding recoveries of fortifying concentrations are:octachlorodipropyletherspike0.01mg/kg,therecoveryis90%~114%octachlorodipropyl ether spike 0. 02 mg/kg, tha récovery is 97% ~ 108%.octachlorodipropyletherspike0.2mg/kg,therecoveryis91%~110%.8

Annex A

(informative)

Chromatogram of the stardardoctachlorodipromyl ether

SN/T1774—2006

the retention time of octachlarodipropyl ether is about 15.4 min.Gas chromatogram of octachlorodlpropyl ether standardFigureA. 1

SN/T 1774-2006

中华人民共和国出人境检验检疫行业标翟

进出口茶叶中八氯二丙醚残留量捡测方法气相色谱法

SN/T 1774-- 2006

中国标准出版社出版

北京复兴门外三里河北街16号

邮政码:100045

网址uzchs.con下载标准就来标准下载网

电话:6852394668517548

中国标准出版社泰皇舟印刷厂印开本880×12301/门6印张1字数16千字2006年8月第一版2006年8儿第一次印刷印数1—2000

书号:155065,2-17038定价10.00元

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

标准图片预览:

- 热门标准

- 商检行业标准(SN)

- SN/T1763.3-2006 出入境口岸生物毒素检验规程 第3部分:蓖麻毒素

- SN/T0720-1997 出口鞋帽、文体用品类商品运输包装检验规程

- SN/T1013-2001 进出口棉、涤棉机织物的线密度测定方法

- SN/T4256-2015 出口普洱茶良好生产规范

- SN/T0810.2-1999 出口显示器技术性能检验规程

- SN0306-93 出口烟花爆竹检验规程

- SN0521-1996 出口油籽中丁酰肼残留量检验方法分光光度法

- SN/T1374-2015 美国白蛾检疫鉴定方法

- SN/T4624.10-2016 入境环保用微生物菌剂检测方法第10部分:淡紫拟青霉

- SN/T3012-2011 钨精矿中三氧化钨含量的测定 X射线荧光光谱法

- SN/T2574-2010 进出口蜂王浆中双甲脒及其代谢产物残留量检测方法 气相色谱-质谱法

- SN/T4890-2017 出口食品中姜黄素的测定高效液相色谱法和液相色谱-质谱/质谱法

- SN/T1424-2011 对日本出口哈密瓜检疫规程

- SN/T3567.11-2017 交叉引物恒温扩增检测方法第11部分:志贺菌

- SN/T0903-2000 进口彩色电视广播接收机安全要求检验规程

- 行业新闻

请牢记:“bzxz.net”即是“标准下载”四个汉字汉语拼音首字母与国际顶级域名“.net”的组合。 ©2025 标准下载网 www.bzxz.net 本站邮件:bzxznet@163.com

网站备案号:湘ICP备2025141790号-2

网站备案号:湘ICP备2025141790号-2